Method for improving conversion rate of grease yeast and regulating composition of grease fatty acid by pretreating alcohol fermentation wastewater

A technology for oily yeast and fermented wastewater, applied in chemical instruments and methods, methods based on microorganisms, biochemical equipment and methods, etc., can solve problems such as high sulfate and ammonia nitrogen content, achieve high added value, simple and feasible process, and improve The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Activated carbon was used to detoxify the ethanol fermentation wastewater, and Trichosporoncutaneum was used for fermentation after the treatment.

[0016] Insert Trichosporon cutaneum from the test tube into 50 mL of activation medium, and at 20° C., activate and cultivate for 24 hours to obtain Trichosporon cutaneum seed liquid. The activated medium is: glucose 20g / L, peptone 10g / L, yeast powder 10g / L L, the balance is water.

[0017] In the control group, activated carbon was not used in the medium of ethanol fermentation wastewater for detoxification, and the seed liquid was directly connected to the medium for fermentation.

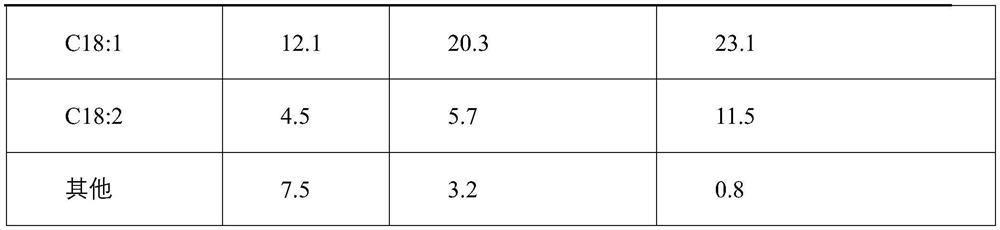

[0018] Activated carbon was added to the ethanol fermentation wastewater in the proportions of 0.5wt% and 5wt% respectively, and the paddle stirring method was adopted. The stirring condition was 50rpm / min for 0.5h. After the stirring was completed, the activated carbon was removed by filtration, and the filtrate was taken to determine the ald...

Embodiment 2

[0027] The ethanol fermentation wastewater was detoxified by attapulgite, and then fermented by Rhodosporidium toruloides after the treatment.

[0028] Put Rhodosporidium toruloides from the test tube into 50 mL of activation medium, 20 ° C, activate and cultivate for 24 hours, to obtain Rhodosporidium toruloides seed liquid, the activation medium is: glucose 20g / L, peptone 10g / L, yeast powder 10g / L L, the balance is water.

[0029] In the control group, the attapulgite was not used for detoxification in the ethanol fermentation wastewater medium, and the seed liquor was directly fermented.

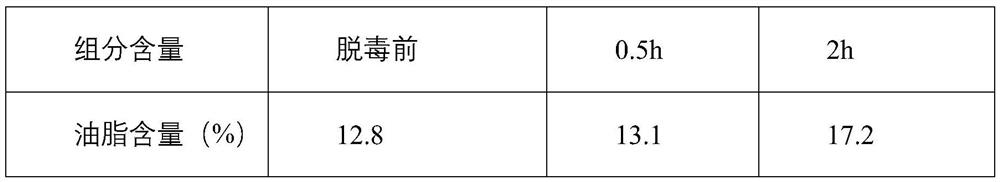

[0030] Attapulgite was added to the ethanol fermentation wastewater in a proportion of 2wt%, and the attapulgite was respectively stirred by anchor stirring for 0.5 and 2 hours, and the rotation speed was 200 rpm / min. (furfural, 5-hydroxymethylfurfural), phenols, ammonia nitrogen content, and measure the light transmittance; after adjusting the pH, the oil yeast seed liquid was connected...

Embodiment 3

[0040] The butanol fermentation wastewater was detoxified by polar macroporous adsorption resin, and Rhodotorula glutinis and Lipomyces starkeyi were used for mixed bacterial fermentation after the treatment.

[0041] The Rhodosporidium toruloides and Lipomyces starkeyi were respectively inserted into 50 mL of activated medium from the test tube, and activated for 24 hours at 20°C to obtain seed liquid. The activated medium was: glucose 20 g / L, peptone 10 g / L, yeast powder 10g / L, the balance is water.

[0042] In the control group, the butanol fermentation wastewater medium did not use polar macroporous adsorption resin for detoxification, and the seed liquid was directly connected to the medium for fermentation.

[0043] The polar macroporous adsorption resin was added to the butanol fermentation wastewater in a proportion of 2 wt%, and stirred for 2 hours by means of screw-type propelling stirring, and the sum of the rotational speed was 100 rpm / min. Resin, take the filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com