Novel efficient zinc-series surface conditioning agent as well as preparation method and application thereof

A surface conditioner and high-efficiency technology, which is applied in the field of zinc-based surface conditioner and its preparation, can solve the problems that the solution is easy to produce sediment, the dense crystal coverage is low, and the service life of the bath is short, so as to shorten the treatment time and eliminate the corrosion. Uniform, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

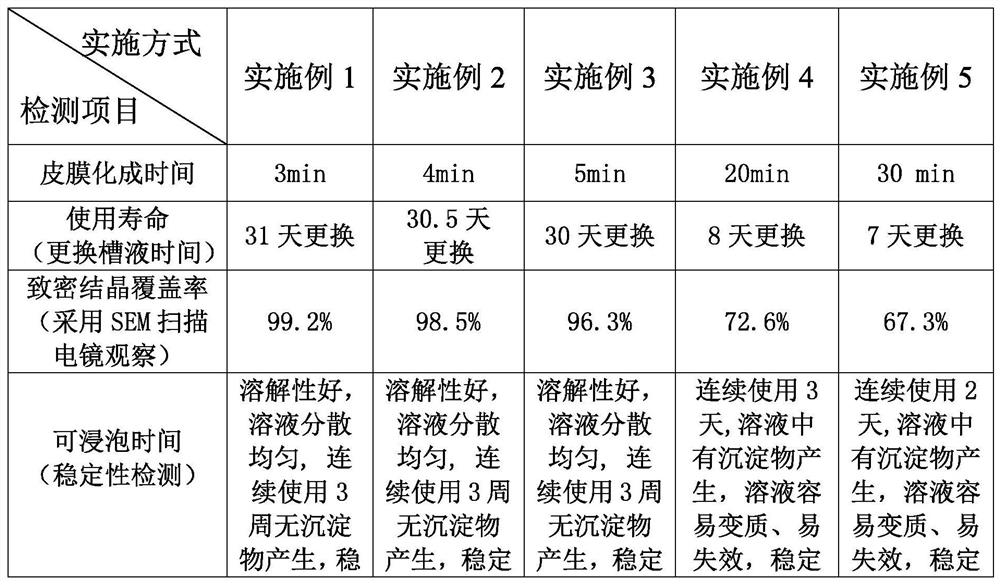

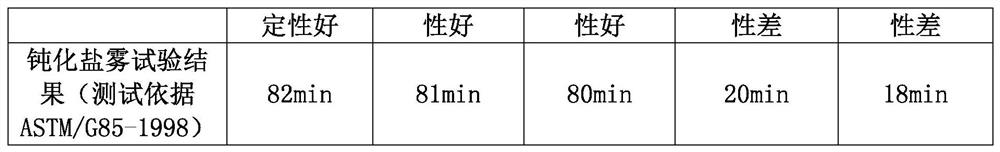

Examples

Embodiment 1

[0032] The present embodiment discloses a novel and efficient zinc-based surface preparation, which is composed of the following components in weight ratio:

[0033] Titanium salt: 35%;

[0034] Polyphosphate: 25%;

[0035] Organic polymer sodium salt: 5%;

[0036] Fluoride: 20%;

[0038] Wherein, the titanium salt includes a mixture of phosphate and titanyl sulfate, and the weight ratio of the mixture of phosphate and titanyl sulfate is 35:1.

[0039] Wherein, the polyphosphate is sodium polyphosphate.

[0040] Wherein, the organic polymer sodium salt includes a mixture of sodium sulfamate, sodium citrate and potassium sodium tartrate, and the weight ratio of sodium sulfamate, sodium citrate and potassium sodium tartrate is 1:1:1.

[0041] Wherein, the fluoride comprises a mixture of sodium fluoride, ammonium bifluoride and fluoroboric acid, and the weight ratio of sodium fluoride, ammonium bifluoride and fluoroboric acid is 1:1:1.

Embodiment 2

[0043] The present embodiment discloses a novel and efficient zinc-based surface preparation, which is composed of the following components in weight ratio:

[0044] Titanium salt: 40%;

[0045] Polyphosphate: 20%;

[0046] Organic polymer sodium salt: 4%;

[0047] Fluoride: 17%;

[0049] Wherein, the titanium salt includes a mixture of phosphate and titanyl sulfate, and the weight ratio of the mixture of phosphate and titanyl sulfate is 35:1.

[0050] Wherein, the polyphosphate is sodium polyphosphate.

[0051] Wherein, the organic polymer sodium salt is sodium sulfamate.

[0052] Wherein, the fluoride is a mixture of ammonium bifluoride and fluoroboric acid, and the weight ratio of ammonium bifluoride to fluoroboric acid is 1:1.

Embodiment 3

[0054] The present embodiment discloses a novel and efficient zinc-based surface preparation, which is composed of the following components in weight ratio:

[0055] Titanium salt: 33%;

[0056] Polyphosphate: 23%;

[0057] Organic polymer sodium salt: 3%;

[0058] Fluoride: 19%;

[0059] Sodium carbonate: 22%.

[0060] Wherein, the titanium salt includes a mixture of phosphate and titanyl sulfate, and the weight ratio of the mixture of phosphate and titanyl sulfate is 35:1.

[0061] Wherein, the polyphosphate is sodium polyphosphate.

[0062] Wherein, the organic polymer sodium salt includes a mixture of sodium citrate and potassium sodium tartrate, and the weight ratio of sodium citrate to potassium sodium tartrate is 1:1.

[0063] Wherein, the fluoride comprises a mixture of sodium fluoride and fluoroboric acid, and the weight ratio of sodium fluoride and fluoroboric acid is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com