Positive pole piece of lithium battery, preparation method of positive pole piece and lithium battery adopting positive pole piece

A technology for positive pole pieces and lithium-ion batteries, which is applied to battery electrodes, non-aqueous electrolyte storage battery electrodes, and secondary batteries. The effect of high specific capacity and slow cycle decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

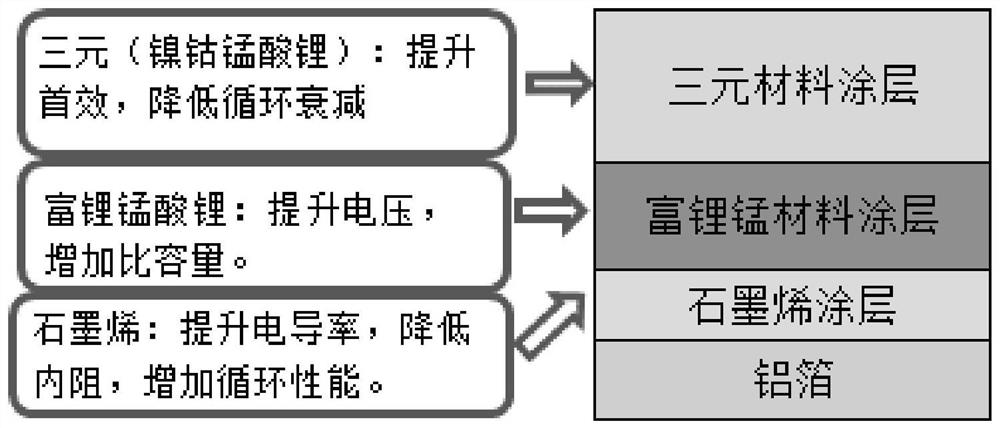

Method used

Image

Examples

preparation example Construction

[0022] (1) Preparation of graphene slurry

[0023] According to graphene powder (mass ratio 85%-89%), binder PVDF (mass ratio 11%-15%), NMP solvent, the binder includes: polyvinylidene fluoride, polyhexafluoropropylene- Copolymers of polyvinylidene fluoride, polyvinyl acetate, polyvinyl alcohol, polyethylene oxide, polyvinyl pyrrolidone, alkylated polyethylene oxide, polyvinyl ether, polymethyl methacrylate, polyvinyl At least one of ethyl acrylate, polytetrafluoroethylene, polyvinyl chloride, polyacrylonitrile, polyvinylpyridine, styrene-butadiene rubber, and acrylonitrile-butadiene rubber;

[0024] The solvent includes at least one of N-methyl-2-pyrrolidone, dimethylformamide, dimethylacetamide, N,N-dimethylaminopropylamine, ethylene oxide and tetrahydrofuran.

[0025] Add solvent according to the solid content of graphene slurry 20%-45%, mix materials according to revolution 25rpm / rotation 3000rpm, after mixing, stir evenly in a stirring pot to obtain graphene slurry, and ...

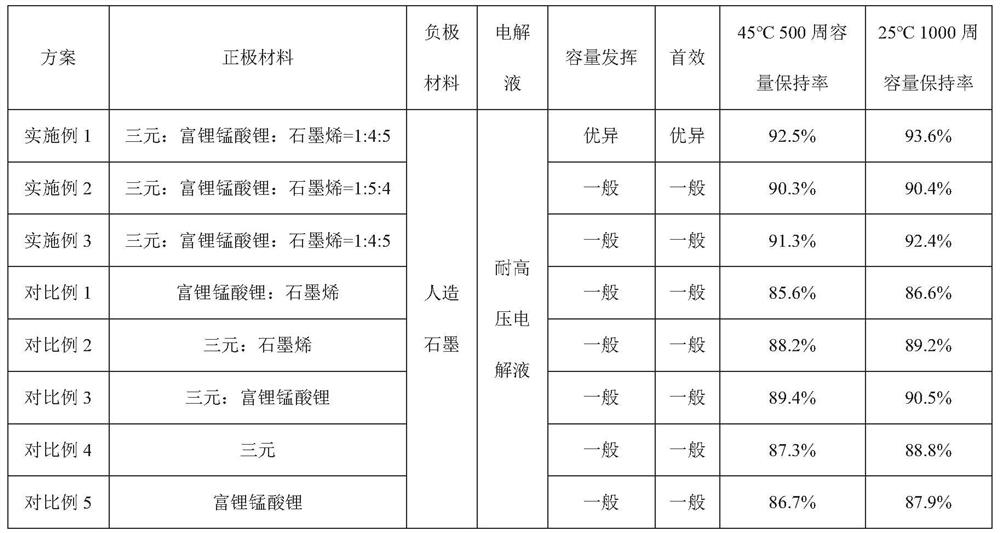

Embodiment 1

[0032] (1) Preparation of graphene slurry

[0033] Take 2000g of graphene powder and 200g of polyvinylidene fluoride and mix, add N-methyl-2-pyrrolidone according to the solid content of graphene slurry 45%, mix materials according to revolution 25rpm / rotation 3000rpm, and stir in a stirring pot after mixing The graphene slurry was uniformly obtained, and the viscosity of the graphene slurry was controlled at 3000cp.

[0034] (2) Preparation of lithium-rich lithium manganate

[0035] First, take 10,000 g of lithium-rich manganate Li (Li 1 / 3 Mn 2 / 3 )O 2 , 208.33g of carbon nanotubes, 208.33g of polyhexafluoropropylene-polyvinylidene fluoride copolymer, mixed with solvent NMP (N-methyl-2-pyrrolidone), the solid content is controlled at 50%, after mixing, in a stirring pot Stir evenly to obtain lithium-rich lithium manganate slurry.

[0036] (3) Preparation of ternary (lithium nickel cobalt manganate)

[0037] 10000g Li (Ni 0.8 Co 0.1 Mn 0.1 )O 2 , 51.5g carbon nanotube...

Embodiment 2

[0041] (1) Preparation of graphene slurry

[0042] Take 2000g graphene powder and 200g polyvinylidene fluoride and mix, add N-methyl-2-pyrrolidone according to the solid content of graphene slurry 45%, mix materials according to revolution 25rpm / rotation 3000rpm, and stir in a stirring pot after mixing The graphene slurry was uniformly obtained, and the viscosity of the graphene slurry was controlled at 3000cp.

[0043] (2) Preparation of lithium-rich lithium manganate

[0044] First, take 10,000 g of lithium-rich manganate Li (Li 1 / 3 Mn 2 / 3 )O 2 , 208.33g carbon nanotubes, 208.33g polyhexafluoropropylene-polyvinylidene fluoride copolymer, mixed with solvent NMP, the solid content is controlled at 50%, and after mixing, stir well in a stirring pot to obtain lithium-rich lithium manganate slurry material.

[0045] (3) Preparation of ternary (lithium nickel cobalt manganate)

[0046] 10000g Li (Ni 0.8 C0 0.1 Mn 0.1 )O 2 , 51.5g carbon nanotubes, 103.1g conductive agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com