Niobium-coated nickel-cobalt-manganese ternary precursor as well as preparation method and application thereof

A precursor, nickel-cobalt-manganese technology, used in chemical instruments and methods, nickel compounds, electrical components, etc., can solve problems such as poor interface stability of nickel-cobalt-manganese ternary cathode materials, battery cycle performance to be improved, and increased production costs. , to achieve a good coating effect, enhance the structure and cycle stability, reduce the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

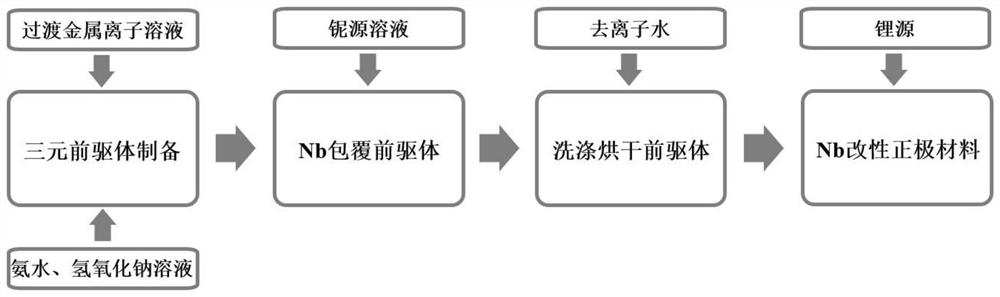

[0041] will NiSO 4 , CoSO 4 , MnSO 4 According to the molar ratio of Ni:Co:Mn=0.9:0.05:0.05, a certain mass was weighed and dissolved in deionized water to prepare 5L of transition metal ion solution with a solubility of 2mol / L and 1L of niobium oxalate solution with a concentration of 0.01mol / L, the concentration of ammonia water is 0.5mol / L, and the concentration of sodium hydroxide solution is 2mol / L. using as figure 1 As shown in the reaction process, the ammonia solution with a concentration of 0.1 mol / L was added in the reactor as the bottom liquid, and the transition metal ion solution and the ammonia solution were respectively added to the reactor using a peristaltic pump, and the flow rate was 2ml / min, and the reaction was maintained. The temperature in the kettle is 55°C, the rotating speed of the stirrer is 800rpm / min, and sodium hydroxide solution is added at the same time, and the flow rate is adjustable within 0.1-10ml / min to keep the pH value of the solution ...

Embodiment 2

[0044] The difference from Example 1 is that the concentration of the niobium oxalate solution is 0.03 mol / L; the temperature is raised to 780° C. in the second stage of lithiation and calcination.

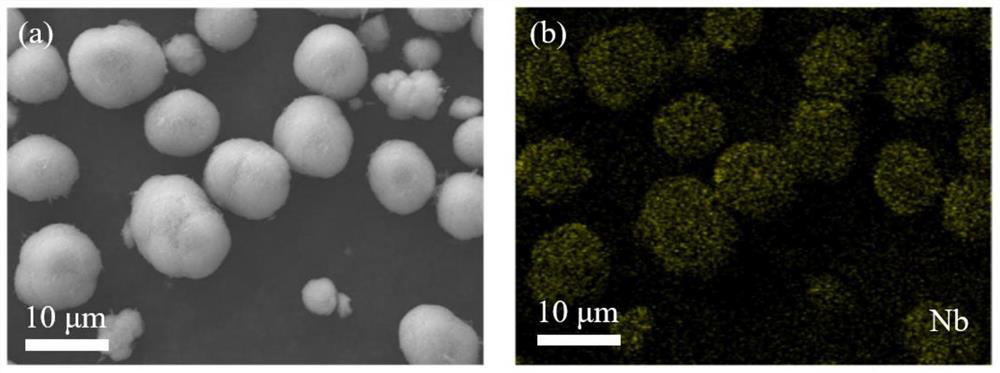

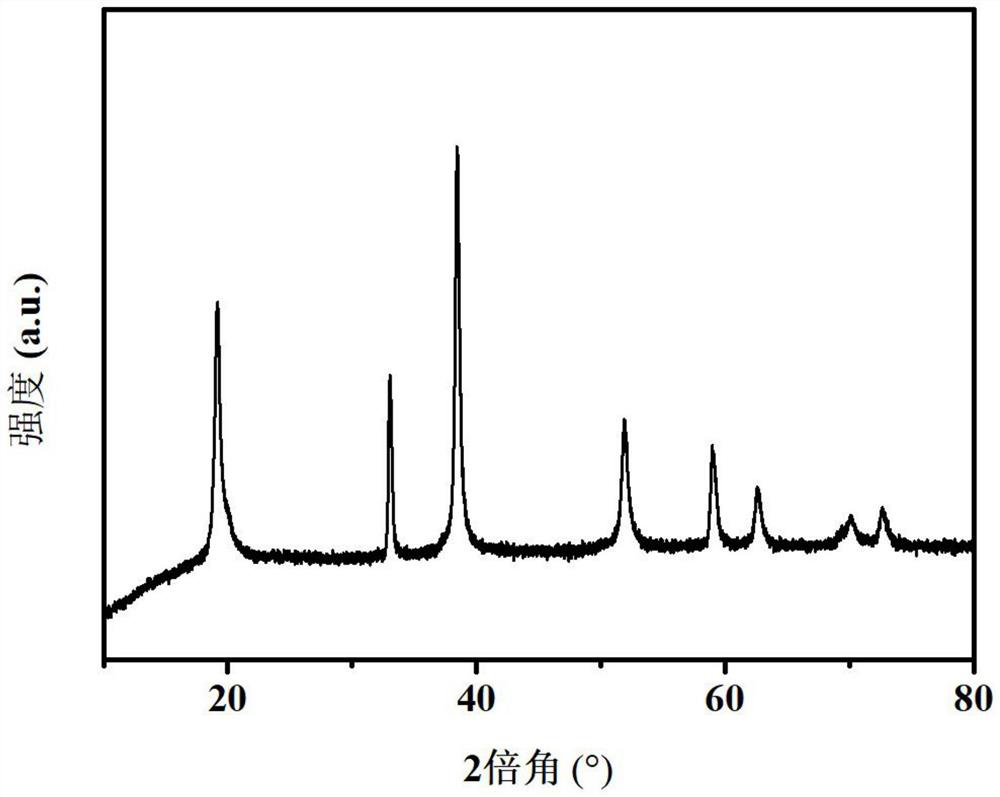

[0045] figure 2 For the SEM image of the niobium-coated nickel-cobalt-manganese ternary precursor in Example 2 and the distribution of Nb element on the particle surface, it can be observed that the Nb element is uniformly distributed on the surface of the precursor; image 3 It is the XRD pattern of the niobium-coated nickel-cobalt-manganese ternary precursor in Example 2. Due to the small amount of coating, only the characteristic peaks of the hydroxide precursor are displayed on the spectrum; Figure 4 The SEM image and the Nb element distribution diagram on the particle surface of the cathode material synthesized from the niobium-coated nickel-cobalt-manganese ternary precursor in Example 2 show that the Nb element is also uniformly distributed on the surface of the cathode m...

Embodiment 3

[0047] The difference from Example 1 is that niobium oxalate is replaced by niobium chloride; the concentration of niobium chloride solution is 0.05mol / L; the first stage of lithiation and calcination is heated to 450°C and kept for 2h, and then the second stage is heated to 750°C and kept for 14h. The electrochemical performance test data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com