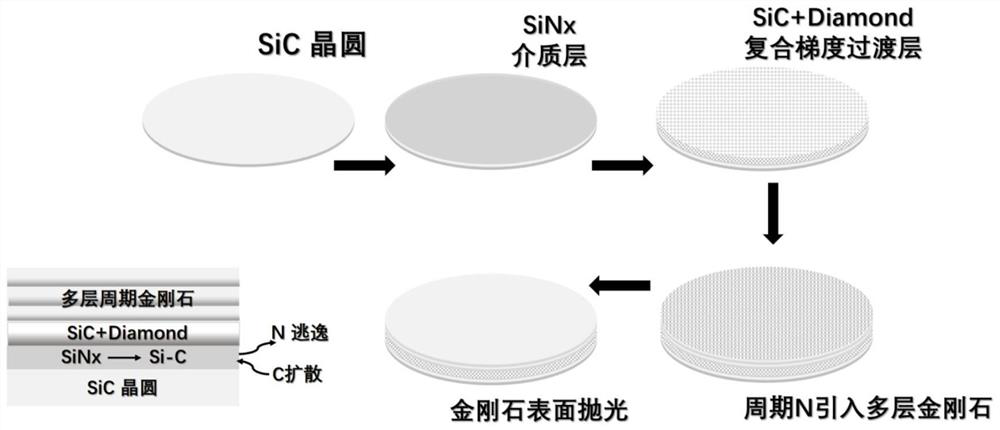

Preparation method of diamond reinforced silicon carbide composite wafer

A diamond-enhanced, silicon carbide crystal technology, applied in the direction of gaseous chemical plating, metal material coating process, solid-state diffusion coating, etc., to achieve the effect of avoiding complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A 5nm SiNx thin layer was plated on the polar surface of SiC carbon after vacuum heat treatment at 800°C for 3h. Subsequently, the microwave hydrogen plasma with a power of 1500W was treated at 400°C for 3 minutes, and then methane with a hydrogen gas flow rate of 5% was introduced, and the power and chamber pressure were increased to the wafer temperature to 680°C, which promoted the formation of carbon films and diamond nucleation for 15 minutes. . Then, the proportion of methane was reduced to 3%, and while maintaining the growth of diamond at 680 °C, silane with a flow rate of hydrogen gas of 1% was introduced, and the flow rate of silane was slowly reduced within 30 minutes until it was turned off, for the preparation of SiC / diamond composite gradient transition Floor. Subsequently, after the diamond has grown for 10 min, nitrogen with a hydrogen flow ratio of 3% was introduced and kept for 3 min, and then turned off. The nitrogen-assisted diamond growth process w...

Embodiment 2

[0042] A 20 nm SiNx thin layer was formed by plating the polar surface of SiC carbon after vacuum heat treatment at 1000 °C for 3 h. Subsequently, the microwave hydrogen plasma with a power of 2000W was treated at 500 °C for 1 min, and then methane with a hydrogen gas flow rate of 10% was introduced, and the power and chamber pressure were increased to the wafer temperature to 720 °C, which promoted the formation of carbon film and diamond nucleation for 5min. . Then, the proportion of methane was reduced to 3%, and silane with a hydrogen gas flow rate of 0.5% was introduced while maintaining the growth of diamond at 720 °C, and the flow rate of silane was slowly reduced within 20min until it was turned off, for the preparation of SiC / diamond composite gradient transition Floor. Subsequently, after the diamond has grown for 15 minutes, nitrogen with a hydrogen flow ratio of 5% is introduced and kept for 5 minutes, and then turned off. The nitrogen-assisted diamond growth proc...

Embodiment 3

[0044] A 15nm SiNx thin layer was formed by plating the polar surface of SiC carbon after vacuum heat treatment at 1000°C for 3h. Subsequently, the microwave hydrogen plasma with a power of 1800W was treated at 450°C for 3 minutes, and then methane with a hydrogen gas flow rate of 7% was introduced, and the power and chamber pressure were increased to the wafer temperature of 700°C, which promoted the formation of carbon films and diamond nucleation for 10 minutes. . Then, the proportion of methane was reduced to 3%, and silane with a hydrogen gas flow rate of 0.1% was introduced while maintaining the growth of diamond at 700 °C, and the flow rate of silane was slowly reduced within 10 min until it was turned off, for the preparation of SiC / diamond composite gradient transition Floor. Subsequently, after the diamond has grown for 15 minutes, nitrogen with a hydrogen flow ratio of 3% is introduced and kept for 5 minutes, and then closed, and the nitrogen-assisted diamond growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com