Low-temperature plasma cold sterilization and mycin degradation method for aspergillus flavus in coarse cereals

A low-temperature plasma and plasma cooling technology, applied in the preservation of seeds by freezing/cooling, preservation of seeds by radiation/electrical treatment, etc., can solve the problem of no simultaneous sterilization method of Aspergillus flavus, cumbersome operation, and degradation effect of plasma treatment. limited and other problems, to avoid the loss of sensory quality, low temperature rise, and shorten working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

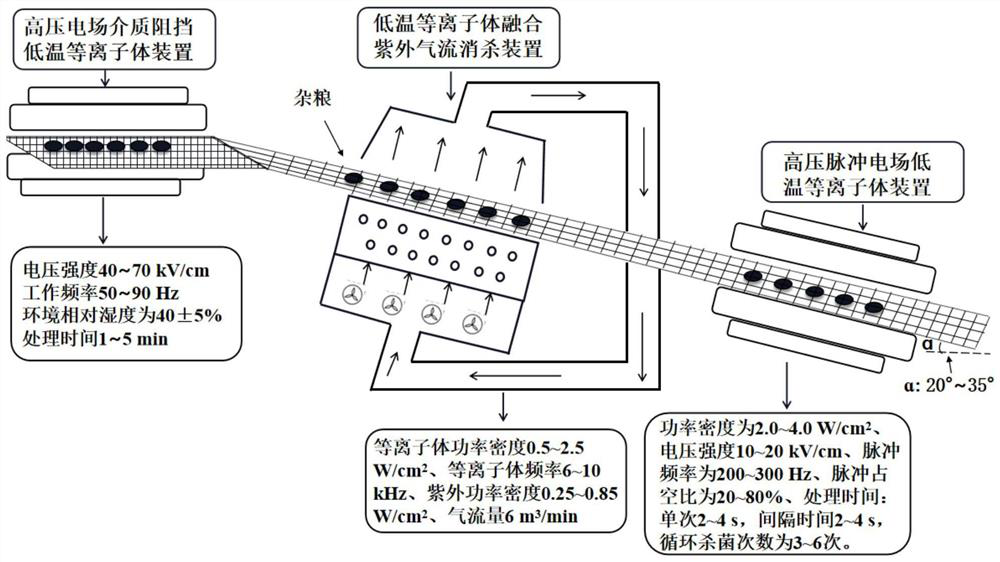

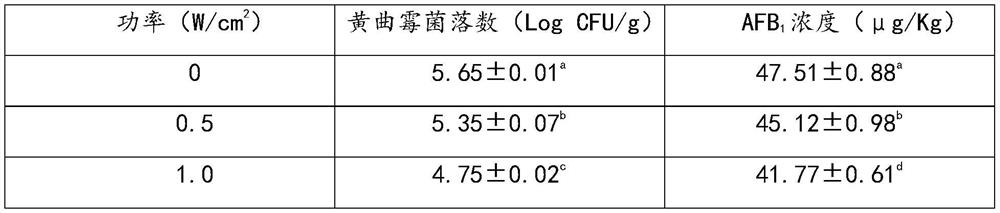

[0032] Sterilization and AFB of Aspergillus flavus in Maize by High Voltage Electric Field Dielectric Barrier Low Temperature Plasma at Different Working Voltage Intensities 1 Degradation effect:

[0033] Will Aspergillus flavus positive or AFB 1 The positive corn samples are laid flat (stacking height 0.5cm) between the high-voltage electric field dielectric barrier low-temperature plasma electrodes, the relative humidity of the environment is 40±5%, the working voltage intensity is 48, 52, 56, 60 and 64kV / cm, and the working frequency The samples were processed under the conditions of 50 Hz and 2 min working time. Counting of Aspergillus flavus was carried out by plate coating counting method; AFB was carried out by fluorescent immunoassay kit. 1 determination of concentration.

[0034] Table 1 Sterilization and AFB of Aspergillus flavus in maize under the condition of different working voltage intensity with high voltage electric field dielectric barrier low temperature ...

Embodiment 2

[0038] Sterilization and AFB of Aspergillus flavus in Maize by High Voltage Electric Field Dielectric Barrier Low Temperature Plasma at Different Operating Frequency 1 Degradation effect

[0039] Will Aspergillus flavus positive or AFB 1 The positive corn samples are laid flat (stacking height 0.5cm) between the high-voltage electric field dielectric barrier low-temperature plasma electrodes, the ambient relative humidity is 40±5%, the working frequency is 50, 60, 70, 80 and 90 Hz, and the working voltage intensity is 64kV / cm, and the samples were processed under the condition of 2 min working time. Counting of Aspergillus flavus was carried out by plate coating counting method; AFB was carried out by fluorescent immunoassay kit. 1 determination of concentration.

[0040] Table 2 Sterilization and AFB of Aspergillus flavus in corn under different working frequencies of high-voltage electric field dielectric barrier low-temperature plasma 1 Degradation effect

[0041] ...

Embodiment 3

[0044] Sterilization and AFB of Aspergillus flavus in Maize under Different Treatment Time of High Voltage Electric Field Dielectric Barrier Low Temperature Plasma 1 Degradation effect

[0045] Will Aspergillus flavus positive or AFB 1 The positive corn samples are laid flat (stacking height 0.5cm) between the high-voltage electric field dielectric barrier low-temperature plasma electrodes, the relative humidity of the environment is 40±5%, the working voltage intensity is 64kV / cm, the working frequency is 50Hz, and the working time is 1, 2, Samples were processed under 4 and 5 min conditions. Counting of Aspergillus flavus was carried out by plate coating counting method; AFB was carried out by fluorescent immunoassay kit. 1 determination of concentration.

[0046] Table 3 Sterilization and AFB of Aspergillus flavus in corn under different treatment time of high voltage electric field dielectric barrier low temperature plasma 1 Degradation effect

[0047] Proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com