Artificial bone material loaded with monatomic copper catalyst and application

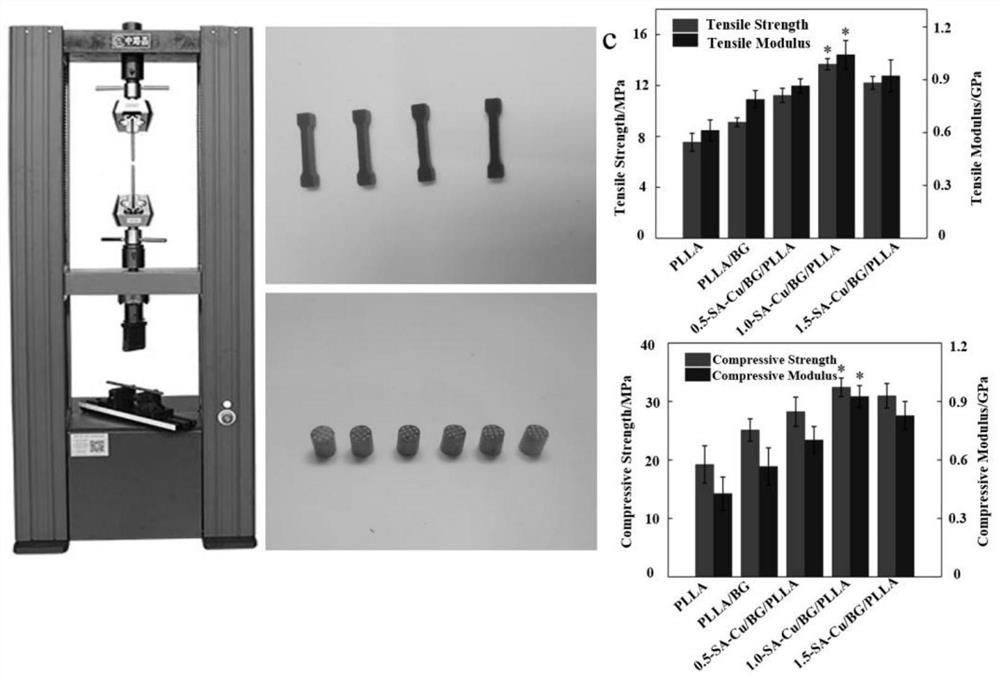

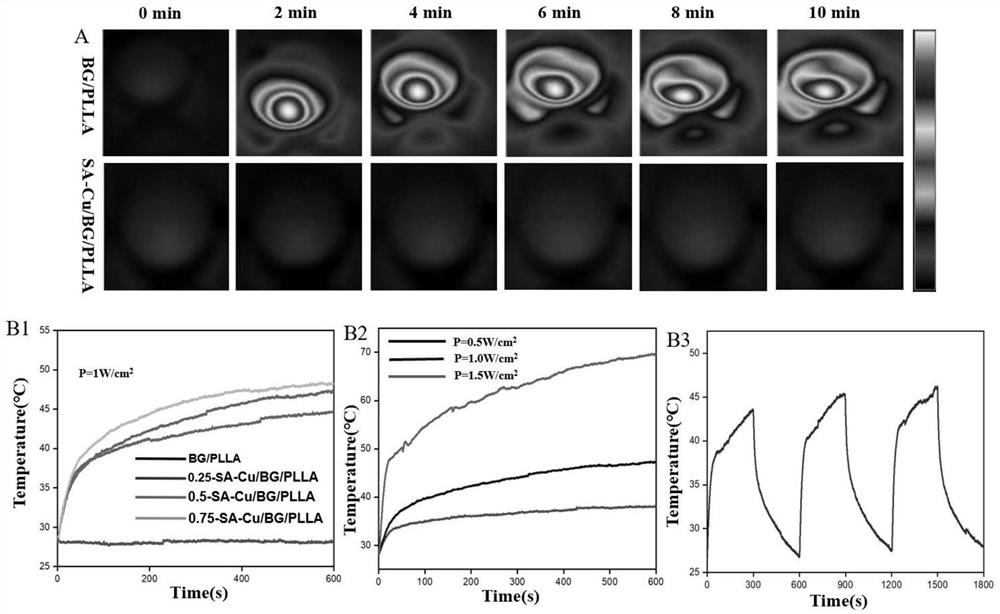

A technology of copper catalyst and artificial bone, applied in additive processing, medical science, prosthesis, etc., can solve the problem of unsatisfactory treatment effect, and achieve the effects of promoting adhesion, high photothermal conversion rate, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 (blank control group)

[0048] (1) Weigh 5g of L-polylactic acid (PLLA) powder with a molecular mass of 150,000 and disperse it in 50mL of anhydrous ethanol solution. The solution is uniformly mixed by magnetic stirring and ultrasonic dispersion. The magnetic stirring time is 10 minutes, and the magnetic stirring speed is 10 minutes. is 300r / min, the ultrasonic dispersion time is 30min, and the ultrasonic dispersion temperature is 50℃.

[0049] (2) After the mixed solution is filtered, it is dried in an electric blast drying oven. The main process parameters are: the drying temperature is 50°C, and the holding time is 24h.

[0050] (3) Put the mixed powder in the laser rapid prototyping system, and sinter layer by layer according to the three-dimensional model. After the sintering is completed, use compressed air to remove the unsintered powder to form the three-dimensional body of the artificial bone required. The main process parameters are: laser The power...

Embodiment 2

[0053] Compared with Example 1, the main difference lies in the addition of bioactive glass (BG) powder, which accounts for 10% of the mass of the composite powder. The specific operations are as follows:

[0054] (1) Weigh 4.5g of PLLA powder with a molecular mass of 150,000 and disperse it in 50mL of anhydrous ethanol solution. The solution is uniformly dispersed and mixed by magnetic stirring and ultrasonic waves. The magnetic stirring time is 10min, and the magnetic stirring speed is 300r / min. , the ultrasonic dispersion time was 30 min, and the ultrasonic dispersion temperature was 50 °C.

[0055] (2) Weigh 0.5g of BG powder, then add the BG powder into the beaker containing the PLLA solution, and the mixed solution is uniformly mixed by magnetic stirring and ultrasonic dispersion technology;

[0056] (3) After the mixed solution is filtered, it is dried in an electric blast drying oven. The main process parameters are: the drying temperature is 50°C, and the holding time...

Embodiment 3

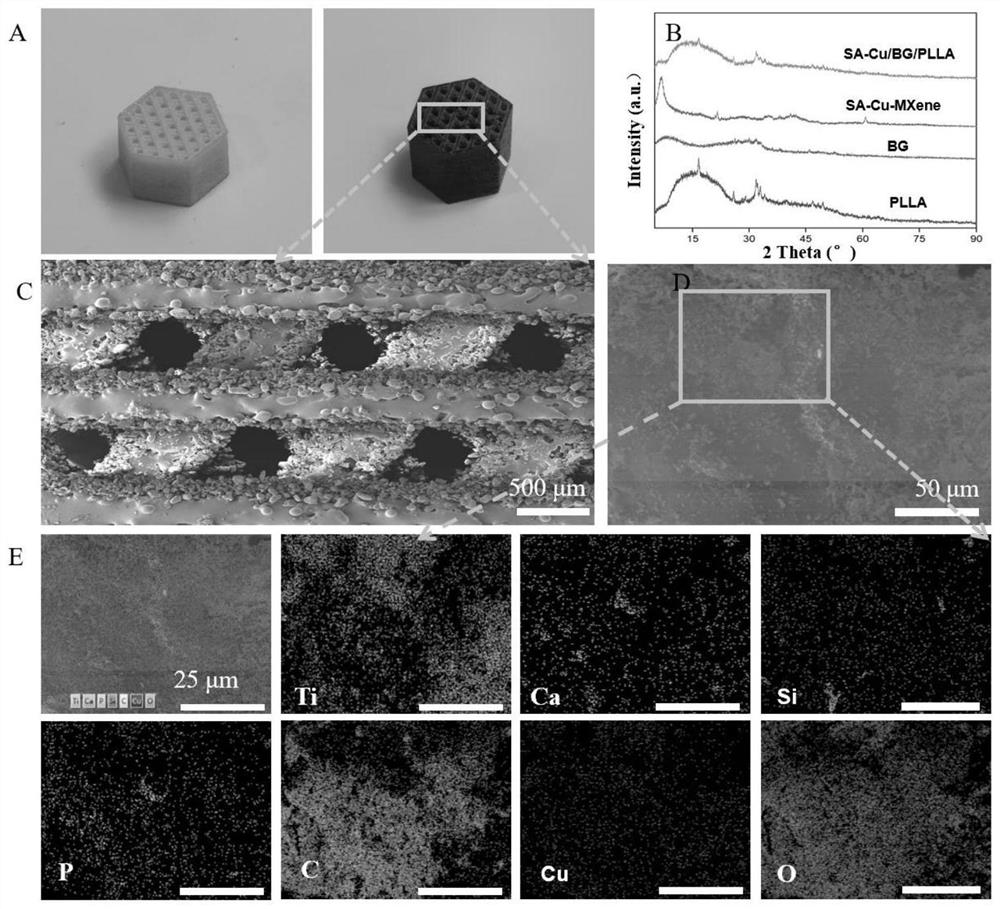

[0060] Compared with Example 1, the main difference is that BG powder is added, which accounts for 10% of the mass ratio of the composite powder, and single-atom copper catalyst (SA-Cu-MXene) powder is added, which accounts for 0.25% of the mass ratio of the composite powder. The specific operation as follows:

[0061] (1) Weigh 4.4875g of PLLA powder with a molecular mass of 150,000 and disperse it in 50mL of anhydrous ethanol solution. The solution is uniformly mixed by magnetic stirring and ultrasonic dispersion. The magnetic stirring time is 10min, and the magnetic stirring speed is 300r / min. , the ultrasonic dispersion time was 30 min, and the ultrasonic dispersion temperature was 50 °C.

[0062] (2) Weigh 0.5g of BG powder, then add the BG powder into the beaker containing the PLLA solution, and the mixed solution is uniformly mixed by magnetic stirring and ultrasonic dispersion technology;

[0063](3) Weigh 0.0125g of powder, add SA-Cu-MXene powder into another beaker ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com