Hydrophilic lubricating anticoagulant hydrogel film as well as preparation method and application thereof

A technology of anticoagulant water and gel, which is applied in anticoagulant treatment, transportation and packaging, and packaged food, etc. It can solve the problems of poor hydrophilicity and lubricity, achieve mild applicability, improve physiological functions, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

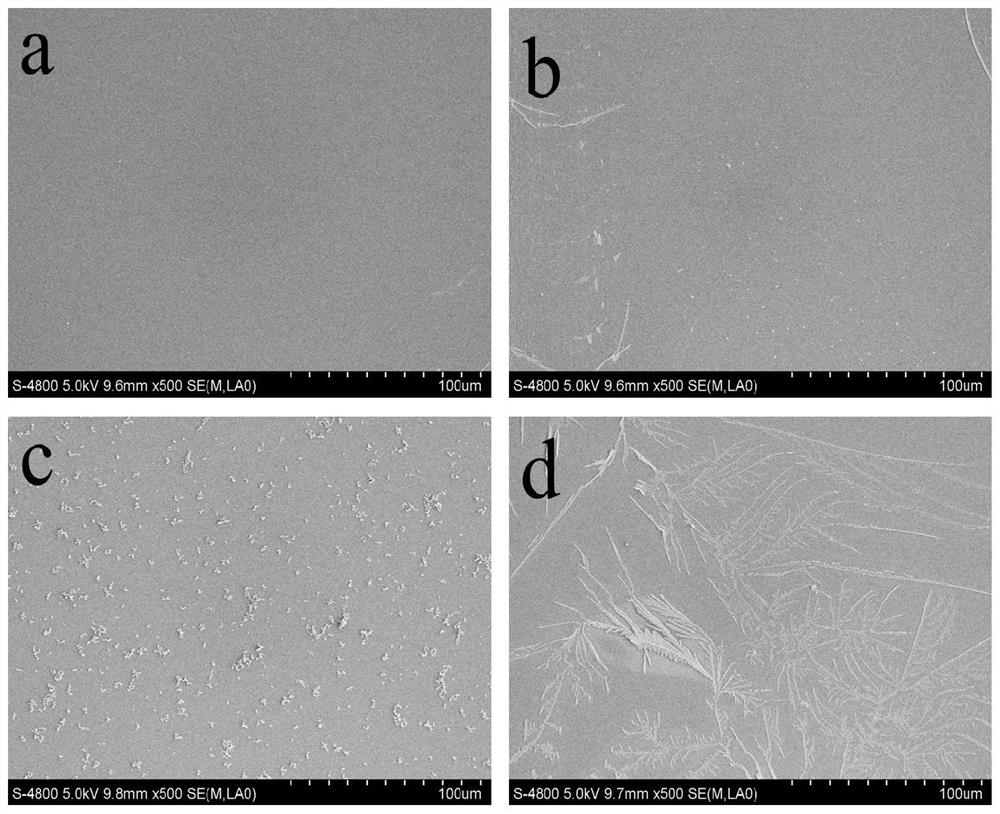

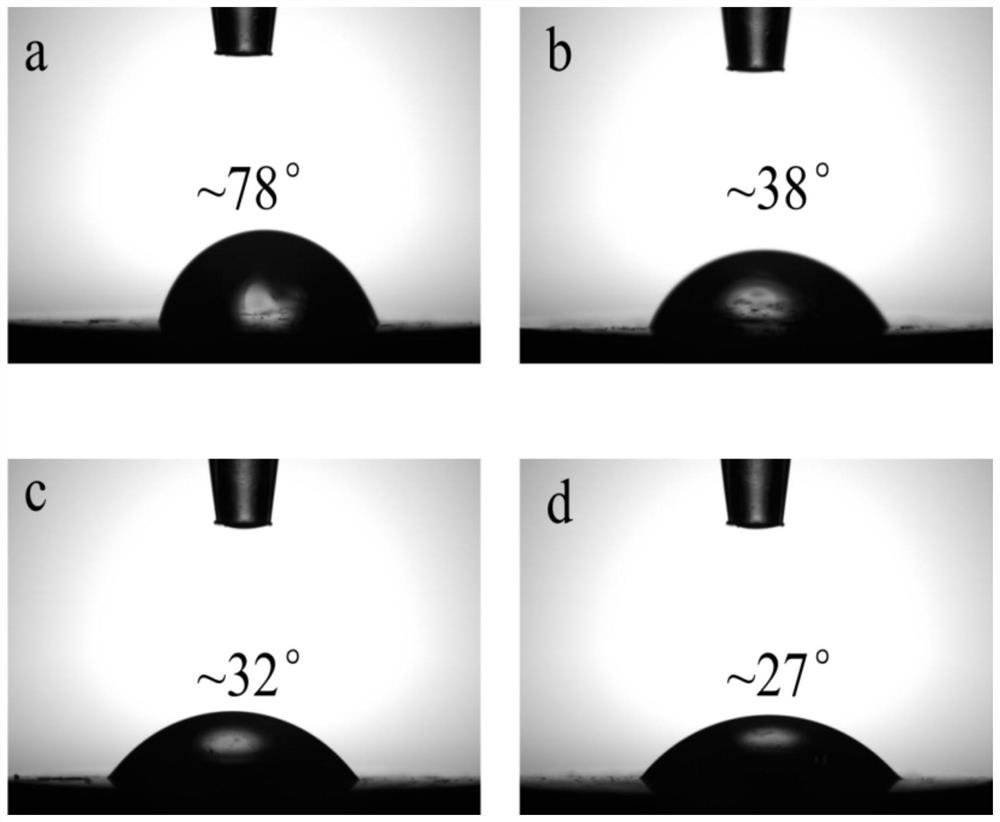

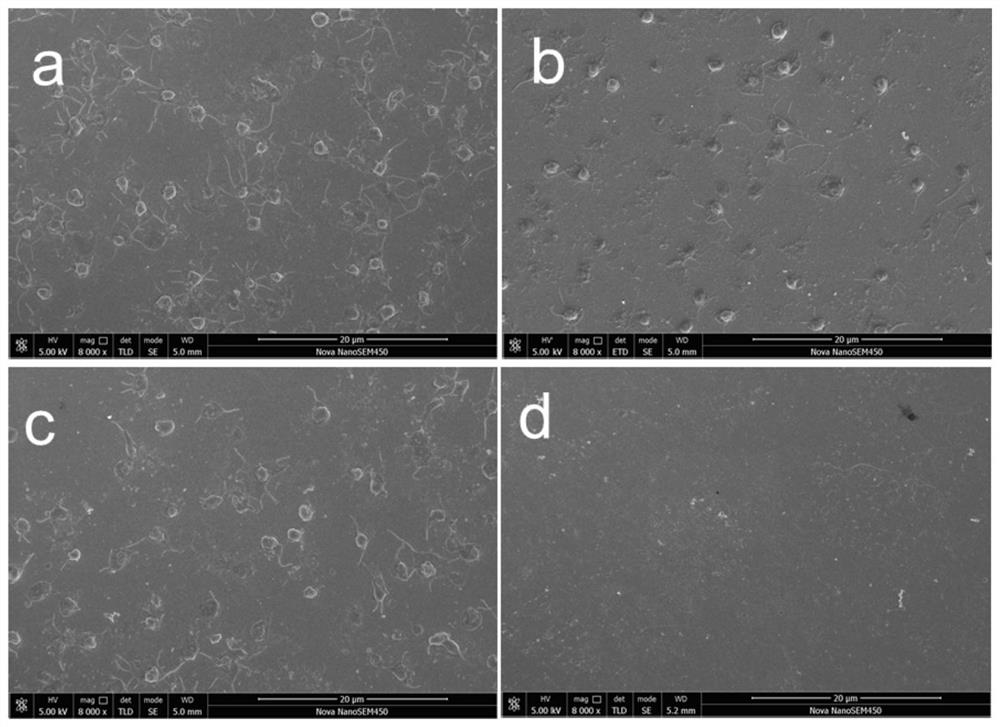

[0038] A kind of hydrophilic lubricating anticoagulation hydrogel film, its preparation method comprises the following steps in sequence:

[0039] (1) Put the PVC catheter material in the plasma chamber, add 100 μL of epoxy silane coupling agent, react for 70 s, then wash with ethanol and water in turn, and dry with nitrogen to obtain the epoxy group-modified catheter material ; Then immersed in 2g / L polyethyleneimine solution, reacted at 30℃ for 30min, and then washed the catheter material with deionized water;

[0040](2) Immerse the catheter material obtained in the step (1) into a solution of epigallocatechin gallate (EGCG) with a concentration of 2 g / L, react with a Schiff base at 30° C. for 15 min, and then use deionized water cleaning catheter material;

[0041] (3) adding sulfonic acid to the hyaluronic acid solution with a concentration of 0.6 g / L to obtain a mixed solution, activated for 30 min to obtain a sulfonated hyaluronic acid solution, the concentration of su...

Embodiment 2

[0044] A kind of hydrophilic lubricating anticoagulation hydrogel film, its preparation method comprises the following steps in sequence:

[0045] (1) Put the PVC catheter material in the plasma chamber, add 50 μL of epoxy silane coupling agent, react for 30 s, then wash with ethanol and water in turn, and dry with nitrogen to obtain the epoxy group-modified catheter material ; Then immersed in 0.5g / L polyethyleneimine solution, reacted at 20℃ for 60min, and then washed the catheter material with deionized water;

[0046] (2) immersing the catheter material obtained in step (1) into the epicatechin solution and the solution with a concentration of 0.1 g / L, at 20 ° C, the Schiff base is reacted for 20min, and then the catheter material is washed with deionized water;

[0047] (3) Add sulfonic acid to the hyaluronic acid solution with a concentration of 0.2 g / L to obtain a mixed solution, activate for 30 min to obtain a sulfonated hyaluronic acid solution, the concentration of s...

Embodiment 3

[0051] A kind of hydrophilic lubricating anticoagulation hydrogel film, its preparation method comprises the following steps in sequence:

[0052] (1) Put the PVC catheter material in the plasma chamber, add 200 μL of epoxy silane coupling agent, react for 120 s, then wash with ethanol and water in turn, and blow dry with nitrogen to obtain the epoxy group-modified catheter material ; Then immersed in 10g / L polyethyleneimine solution, reacted at 40°C for 10min, and then washed the catheter material with deionized water;

[0053] (2) Immerse the catheter material obtained in step (1) into an epicatechin gallate solution with a concentration of 10 g / L, react with a Schiff base at 40° C. for 5 min, and then wash the catheter material with deionized water ;

[0054] (3) Add sulfonic acid to the hyaluronic acid solution with a concentration of 1 g / L to obtain a mixed solution, activate for 30 min to obtain a sulfonated hyaluronic acid solution, the concentration of sulfonic acid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com