Macroelement liquid fertilizer as well as preparation method and application thereof

A technology of liquid fertilizers and macronutrients, applied in liquid fertilizers, applications, fertilizer mixtures, etc., can solve the problems of single nutrient element formula, low nutrient content, high production cost, etc., and achieve high total nutrient content, comprehensive nutrient components, and physical and chemical properties stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

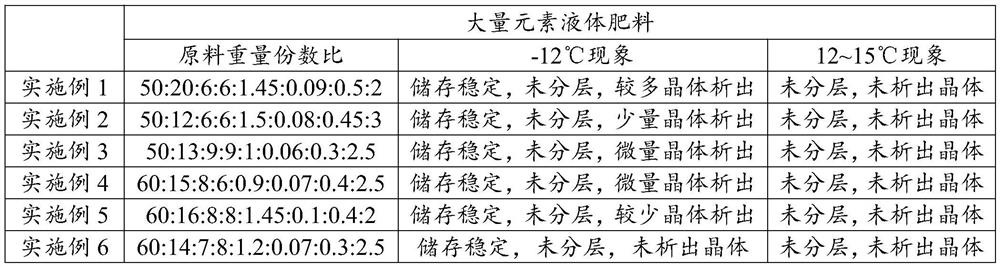

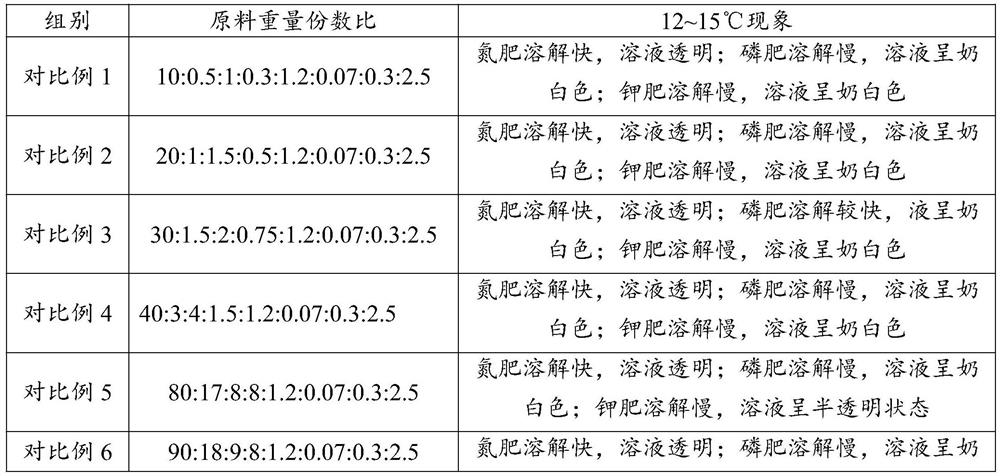

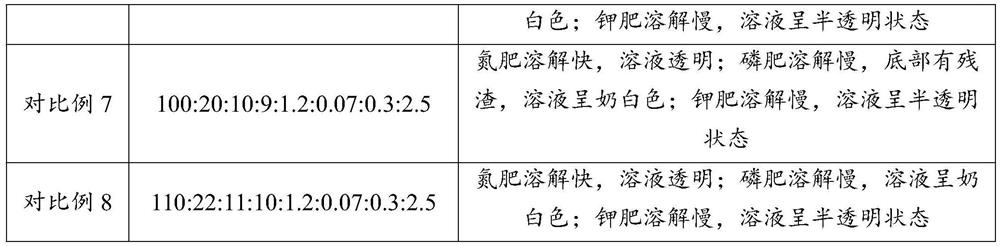

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the above-mentioned large-element liquid fertilizer, comprising the following steps:

[0042] Mix ammonium nitrate solution, nitrogen fertilizer, potash fertilizer, phosphate fertilizer and accelerator, and stir at 20~40℃ for 20~30min to obtain primary mixed solution;

[0043] Mixing the primary mixed solution, polymer dispersant and thickener, and stirring for 40-50 min to obtain primary liquid fertilizer;

[0044] The primary liquid fertilizer and the antifreeze are mixed to obtain the macroelement liquid fertilizer.

[0045] In the present invention, ammonium nitrate solution, nitrogen fertilizer, potash fertilizer, phosphate fertilizer and accelerator are mixed and stirred at 20-40 DEG C for 20-30 minutes to obtain a primary mixed solution. In the present invention, the ammonium nitrate solution preferably further includes pretreatment before being mixed with nitrogen fertilizer, potash fertilizer, phospha...

Embodiment 1

[0054] A liquid fertilizer with a large number of elements, consisting of the following components: 50 mL of ammonium nitrate solution, 20 g of urea, 6 g of diammonium phosphate, 6 g of potassium chloride, 0.8 g of citric acid, 0.2 g of sodium salicylate, 0.45 g of sulfamic acid, 0.09 g of acrylamide, 0.15 g of sodium carboxymethyl cellulose, 0.35 g of xanthan gum and 2 mL of methanol; the mass concentration of ammonium nitrate in the ammonium nitrate solution is 15%.

[0055] The preparation method of described macroelement liquid fertilizer consists of the following steps:

[0056] S1. put ammonium nitrate solution into the stirring mixer, control the mixing temperature to 30°C, the stirring speed to be 70 rev / min, and the stirring time to be 5min;

[0057] S2. slowly add urea, diammonium phosphate, potassium chloride, citric acid, sodium salicylate, sulfamic acid to the ammonium nitrate solution, and stir for 25min while adding, keeping stirring speed at 70 rev / min;

[005...

Embodiment 2

[0062] A liquid fertilizer with a large number of elements, consisting of the following components: 50mL of ammonium nitrate solution, 12g of urea, 6g of diammonium phosphate, 6g of potassium chloride, 0.4g of citric acid, 0.5g of sodium salicylate, 0.6g of sulfamic acid, 0.08 g of acrylamide, 0.1 g of sodium carboxymethyl cellulose, 0.35 g of xanthan gum and 3 mL of methanol; the mass concentration of ammonium nitrate in the ammonium nitrate solution is 15%.

[0063] The preparation method of described macroelement liquid fertilizer consists of the following steps:

[0064] S1. put ammonium nitrate solution into the stirring mixer, control the mixing temperature to 30°C, the stirring speed to be 70 rev / min, and the stirring time to be 7min;

[0065] S2. slowly add urea, diammonium phosphate, potassium chloride, citric acid, sodium salicylate, sulfamic acid to the ammonium nitrate solution, and stir for 25min while adding, keeping stirring speed at 70 rev / min;

[0066] S3. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com