Mesoporous molecular sieve doped acetylated molecularly imprinted polymer and construction of micro-fluidic chip platform

A mesoporous molecular sieve and molecular imprinting technology, applied in other chemical processes, laboratory containers, chemical instruments and methods, etc., can solve the problems of cumbersome steps in multi-dimensional systems, difficulty in online sample processing, incompatible operating conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

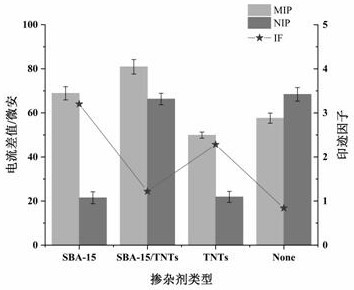

[0042] Example 1: Optimizing the preparation conditions of the molecularly imprinted polymer is to improve its specificity to the template molecule and make the imprinting effect more pronounced. In order to investigate the effect of functional monomer / crosslinker ratio and dopant type on the imprinting effect and adsorption effect of the template. The specific operation steps are as follows:

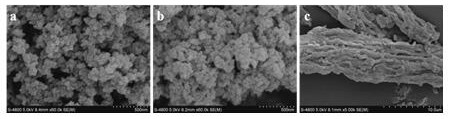

[0043] a. Preparation method of SBA-15 mesoporous molecular sieve doped acetylated molecularly imprinted polymer:

[0044] The mass fraction of SBA-15 mesoporous molecular sieve (8-12 nm) 0.50%, template KacQLAT (95%, Shanghai Qiangyao Biotechnology Co., Ltd., product number 04010047537) 1.44%, functional monomer zinc acrylate 3.97%, cross-linking agent PEGDA 15.81% and EDMA 9.50%, initiator azobisisobutyronitrile 0.46%, dissolved in a mixed solution of porogen methanol 36.05% and N, N-dimethylformamide 32.27%; ultrasonic (power 150 W) dissolved After 15 min, it was dissolved and clar...

Embodiment 2

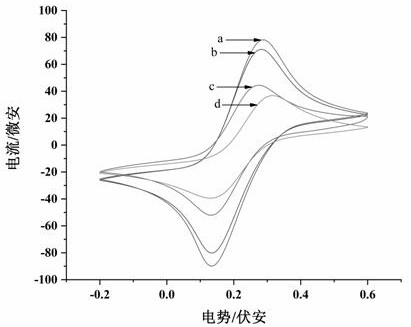

[0050] Example 2: Application of the prepared electrochemical sensor based on molecularly imprinted electrode technology in detecting template KacQLAT. Specific steps are as follows:

[0051] a. Preparation of SBA-15@MIP / GCE electrical sensor:

[0052] The SBA-15@MIP / GCE electrical sensor was fabricated using the drop coating method. First, glassy carbon electrodes (GCE) were polished on a polishing cloth with 1.0, 0.3, and 0.05 μM GCE alumina aqueous slurries, respectively, and then washed with sulfuric acid solution (1 M), deionized water, and ethanol for 10 min, respectively. After that, 2 mg of imprinted polymer was added to 1 mL of chitosan solution (0.5% wt, containing 20 μL of acetic acid), followed by 50 μL (1 mg / mL) of MWCNT DMF solution to increase conductivity sex. In order to uniformly disperse the polymer and multi-walled carbon nanotubes, the prepared mixture was sonicated and mixed for 5 min. Finally, 10 μL of the SBA-15@MIP mixture was drop-coated on the su...

Embodiment 3

[0060] Example 3: In order to reduce sample consumption and loss, shorten analysis time and cost, and achieve the goal of automation and integration, a multi-functional microfluidic chip integration platform was built. Specific steps are as follows:

[0061] a. Sample online processing:

[0062] The denaturation chip is connected to protein fractionation before, followed by enzyme reactor and acetylation molecular imprinting enrichment column. The four units are connected in series with thin connecting tubes. The length and size requirements of the denaturation channel and the location distribution of each reservoir are comprehensively considered. The online denaturation column is divided into denaturation I area and denaturation II area. Each area contains multiple groups of serpentine channels, each channel is 2cm long, and the total length of the channel can be adjusted arbitrarily. All channels are 250 μm wide and 100 μm deep. The prepared chip is placed on the jig, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com