A preparation method and application of click chemical imprinted lincomycin molecular composite film

A technology of lincomycin and click chemistry, applied in chemical instruments and methods, other chemical processes, membranes, etc., can solve the problems of lower thermal stability requirements of basement membranes, long and shortened preparation time of molecularly imprinted membranes, etc. Achieve the effects of improved selective separation efficiency, improved toughness and anti-pollution performance, and short polymerization reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

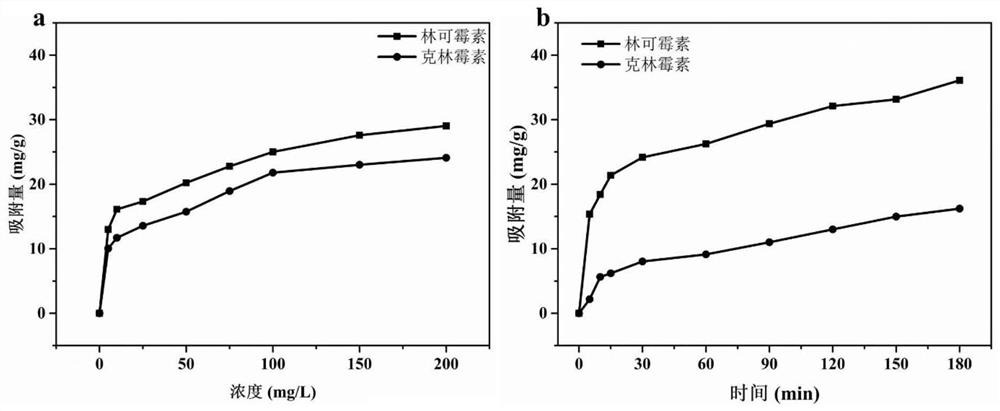

Embodiment 1

[0054] S1. Preparation of PVDF blank membrane:

[0055] Dissolve 3g of PVDF powder in 25ml of organic solvent N-methylpyrrolidone, stir and mix at 50°C for 12 hours to obtain a casting solution, let it stand for 24 hours, obtain a PVDF film through phase inversion and dry it in the air;

[0056] Preparation of S2, PVDF hydrophilic modified membrane:

[0057] 0.1211g tris(hydroxymethyl)aminomethane hydrochloride, 0.4g polyethyleneimine and 0.2g dopamine hydrochloride are dissolved in 100ml water to obtain a mixed solution, and the pH of the solution is adjusted to 8.5 with hydrochloric acid and sodium hydroxide, and the basement membrane Immerse in the mixed solution, shake at room temperature for 6 hours, wash and dry to obtain PVDF hydrophilic modified membrane;

[0058] Preparation of S3, KH570 modified PVDF hydrophilic membrane:

[0059] Disperse the PVDF hydrophilic modified membrane prepared in S2 in a mixed solution containing 80mL ethanol and 20mL water, then add 1ml ...

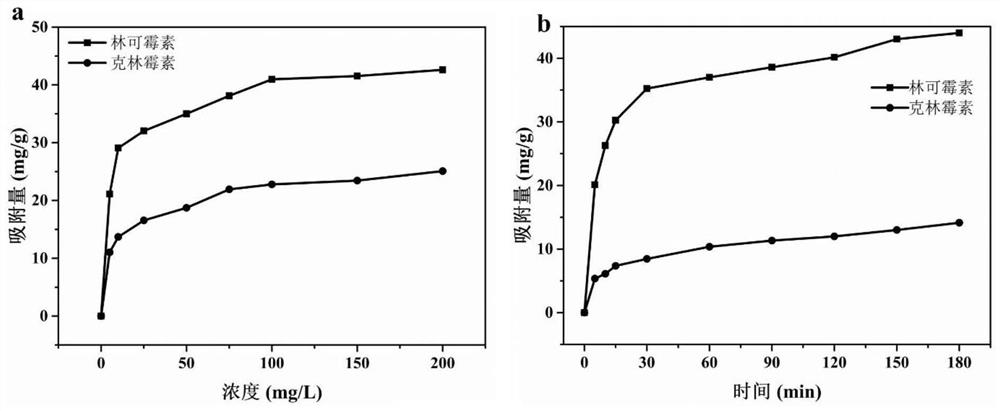

Embodiment 2

[0069] S1. Preparation of PVDF blank membrane:

[0070] Dissolve 4g of PVDF powder in 25ml of organic solvent N-methylpyrrolidone, stir and mix at 50°C for 24 hours to obtain a casting solution, let it stand for 24 hours, obtain a PVDF film through phase inversion and dry it in the air;

[0071] Preparation of S2, PVDF hydrophilic modified membrane:

[0072] 0.1211g tris(hydroxymethyl)aminomethane hydrochloride, 0.5g polyethyleneimine and 0.2g dopamine hydrochloride are dissolved in 100ml water to obtain a mixed solution, and the pH of the solution is adjusted to 8.5 with hydrochloric acid and sodium hydroxide, and the basement membrane Immerse in the mixed solution, shake at room temperature for 12 hours, wash and dry to obtain PVDF hydrophilic modified membrane;

[0073] Preparation of S3, KH570 modified PVDF hydrophilic membrane:

[0074] Disperse the PVDF hydrophilically modified membrane prepared in S2 in a mixed solution containing 80mL ethanol and 20mL water, then add...

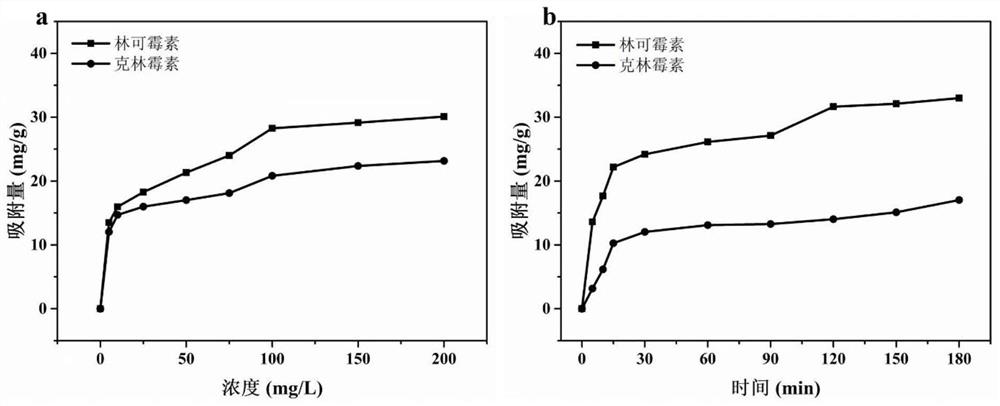

Embodiment 3

[0085] S1. Preparation of PVDF blank membrane:

[0086] Dissolve 5g of PVDF powder in 25ml of organic solvent N-methylpyrrolidone, stir and mix at 50°C for 36 hours to obtain a casting solution, let it stand for 24 hours, obtain a PVDF film through phase inversion and dry it in the air;

[0087] Preparation of S2, PVDF hydrophilic modified membrane:

[0088] 0.1211g tris(hydroxymethyl)aminomethane hydrochloride, 0.6g polyethyleneimine and 0.2g dopamine hydrochloride are dissolved in 100ml water to obtain a mixed solution, and the pH value of the solution is adjusted to 8.5 with hydrochloric acid and sodium hydroxide, and the basement membrane Immerse in the mixed solution, shake at room temperature for 24 hours, wash and dry to obtain PVDF hydrophilic modified membrane;

[0089] Preparation of S3, KH570 modified PVDF hydrophilic membrane:

[0090] Disperse the PVDF hydrophilically modified membrane prepared in S2 in a mixed solution containing 80mL ethanol and 20mL water, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com