Preparation method of catalyst for catalytic combustion of VOCs (Volatile Organic Compounds) and product thereof

A catalytic combustion and catalyst technology, which is applied in the field of VOCs treatment, can solve the problems of expensive precious metals and single performance, and achieve the effect of simple preparation method, excellent product performance and improved crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

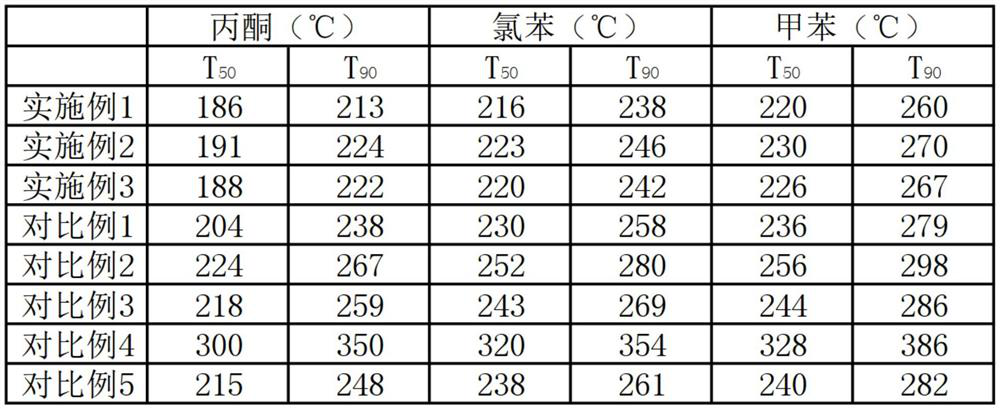

Examples

Embodiment 1

[0026] A preparation method for catalytic combustion of VOCs catalyst is characterized in that: comprising the following steps:

[0027] (1) the gallium nitrate of 5mmol and the trisodium citrate of 1.5mmol are added in the mixed solution of 100mL ethanol and water, wherein the volume ratio of ethanol and water is 1:1, magnetic stirring at room temperature, described stirring speed is 350rpm , stirring for 1 h, poured into the hydrothermal reaction kettle after mixing evenly, and then reacted at 190 ° C for 20 h. After the reaction was completed, the obtained suspension was filtered after the reaction kettle was cooled, washed with ethanol, centrifuged and filtered for 3 times, and then in Drying at 100°C for 13h, then calcining at 400°C for 30h to obtain gallium oxide;

[0028] (2) adding gallium oxide to the mixture containing copper nitrate and cerium nitrate, 1g urea, 4g polyvinylpyrrolidone, 55mL ethanol and 55mL deionized water and stirring, the stirring speed is 350rpm,...

Embodiment 2

[0030] A preparation method for catalytic combustion of VOCs catalyst, comprising the following steps:

[0031] (1) the gallium acetate of 5mmol and the sodium acetate of 2mmol are added in the mixed solution of 100mL ethanol and water, wherein the volume ratio of ethanol and water is 1:1, magnetic stirring at room temperature, described stirring speed is 400rpm, stirring time 0.5h, after mixing evenly, poured into the hydrothermal reaction kettle, and then reacted at 200°C for 12h. After the reaction was completed, after the reaction kettle was cooled, the obtained suspension was filtered, washed with ethanol, centrifuged and filtered 3 times, and then at, 120 Drying at ℃ for 12h, then calcining at 500℃ for 10h to obtain gallium oxide;

[0032](2) adding gallium oxide to the mixture containing copper chloride and cerium acetate, 3g urea, 5g polyvinylpyrrolidone, 60mL ethanol and 60mL deionized water and stirring, the stirring speed is 400rpm, the stirring time is 1h, and the ...

Embodiment 3

[0034] A preparation method for catalytic combustion of VOCs catalyst, comprising the following steps:

[0035] (1) the gallium chloride of 5mmol and the trisodium citrate of 1mmol are added in the mixed solution of 100mL ethanol and water, wherein the volume ratio of ethanol and water is 1:1; Magnetic stirring at room temperature, described stirring speed is 300rpm , stirring time for 1h, poured into the hydrothermal reaction kettle after mixing evenly, and then reacted at 180 ℃ for 24h, after the reaction was completed, after the reaction kettle was cooled, the obtained suspension was filtered, washed with ethanol, centrifuged and filtered for 3 times, and then in , dried at 80 °C for 14 h, and then calcined at 300 °C for 40 h to obtain gallium oxide;

[0036] (2) adding gallium oxide to the mixture containing copper acetate and cerium chloride, 1g urea, 3g polyvinylpyrrolidone, 50mL ethanol and 50mL deionized water and stirring, the stirring speed is 300rpm, the stirring ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com