Binuclear ruthenium catalyst as well as preparation method and application thereof

A catalyst, di-nuclear ruthenium technology, applied in the field of organometallic catalysts for olefin polymerization, can solve the problems of catalyst synthesis and purification difficulties, and achieve the effects of easy operation, mild synthesis conditions, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

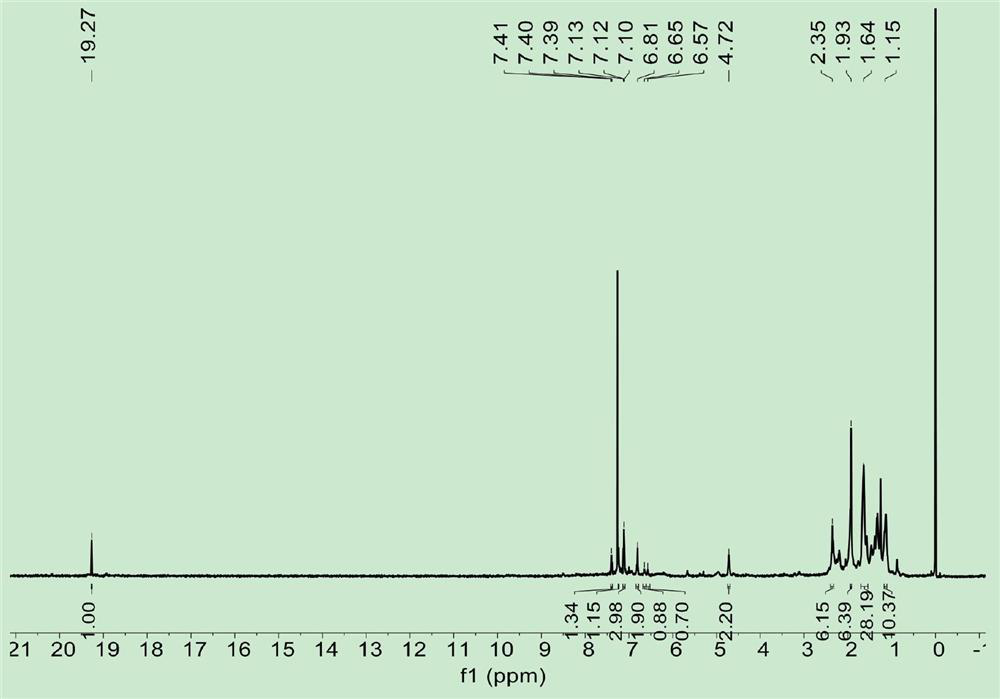

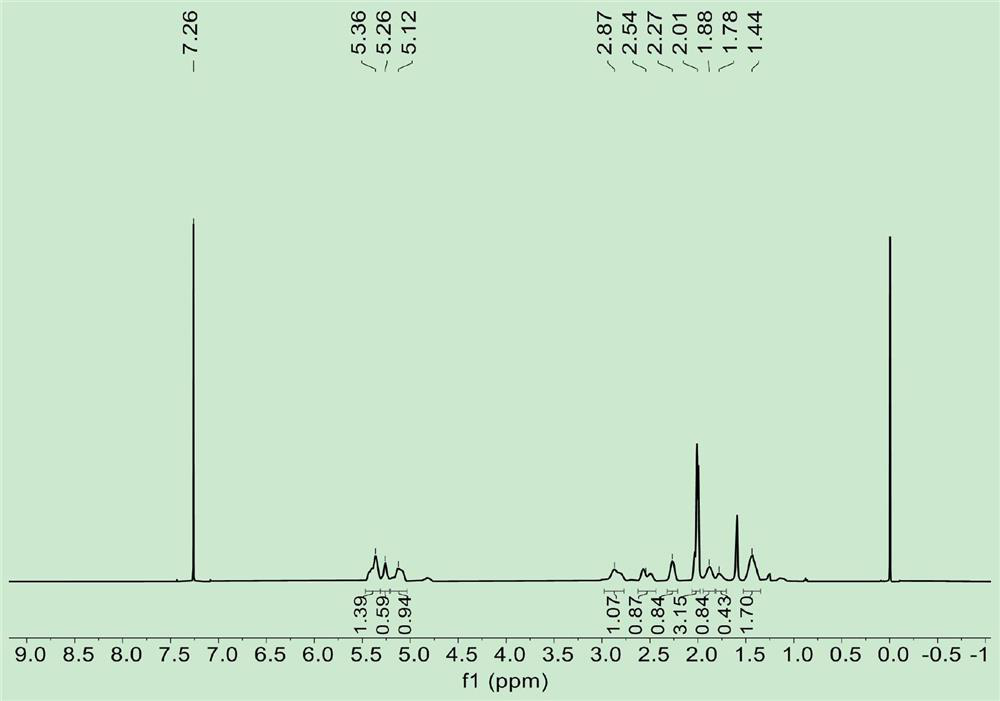

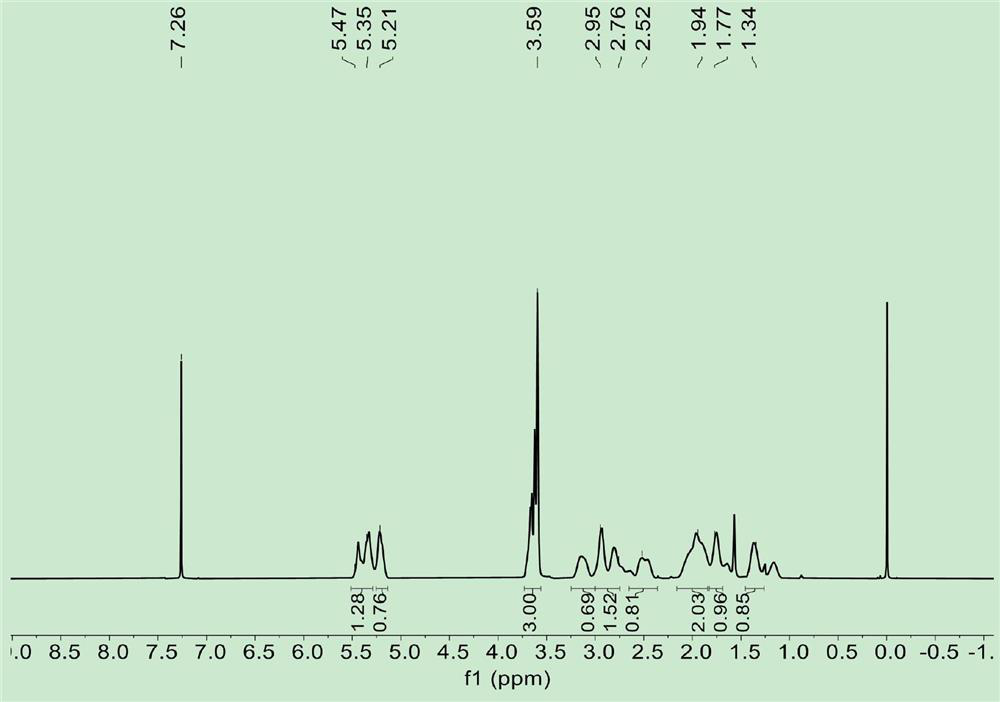

Embodiment 1

[0040] A preparation method of a dual-nuclear ruthenium catalyst, comprising the following steps:

[0041] (1) Preparation of dual-nuclear ruthenium catalyst precursor: under the protection of nitrogen flow, weigh 1,10-dibromodecane (201mg, 0.67mmol) into a 15mL Ace pressure-resistant tube, add 5mL of toluene, and then add 2,4, 6-Trimethylphenylimidazole (250 mg, 1.34 mmol), put the Ace pressure-resistant tube in an oil bath, stir at 110 ° C for 12 h, a light yellow reaction solution precipitates a solid, remove the solvent in vacuo, and dissolve the solid in two. Chloromethane becomes a light yellow liquid, which is dropped into diethyl ether to separate out white powder, which is uniformly sonicated and left to stand, repeatedly washed with dichloromethane and diethyl ether, left to stand in a refrigerator, and the solvent is removed in vacuo to obtain a white powder decane even bis-1-(2, 4,6-Trimethylphenyl)-imidazole bromide 293 mg, yield 65%;

[0042] (2) Preparation of ...

Embodiment 2

[0052] A preparation method of a dual-nuclear ruthenium catalyst, comprising the following steps:

[0053] (1) Preparation of dual-nuclear ruthenium catalyst precursor: under the protection of nitrogen flow, weigh 1,5-dibromopentane (154 mg, 0.67 mmol) into a 15 mL Ace pressure-resistant tube, add 5 mL of toluene, and then add 2, 4, 6-Trimethylphenylimidazole (250 mg, 1.34 mmol), put the Ace pressure-resistant tube in an oil bath, stir at 110 ° C for 12 h, a light yellow reaction solution precipitates a solid, remove the solvent in vacuo, and dissolve the solid in two. Chloromethane becomes a light yellow liquid, which is dropped into diethyl ether to separate out white powder, which is uniformly sonicated and left to stand, repeatedly washed with dichloromethane and diethyl ether, left to stand in a refrigerator, and the solvent is removed in vacuo to obtain a white powder of pentane bis-1-(2, 4,6-Trimethylphenyl)-imidazolium bromide 279 mg (69%);

[0054] (2) Preparation of...

Embodiment 3

[0060] A preparation method of a dual-nuclear ruthenium catalyst, comprising the following steps:

[0061] (1) Preparation of binuclear ruthenium catalyst precursor: under the protection of nitrogen flow, 1,4-bis(bromomethyl)benzene (305 mg, 1.15 mmol) was weighed into a 15 mL Ace pressure-resistant tube, 5 mL of dichloromethane was added, and then 2,4,6-Trimethylphenylimidazole (453mg, 2.43mmol) was added, the Ace pressure-resistant tube was placed in an oil bath, and after stirring at 45°C for 12h, a light yellow reaction solution precipitated a solid, and the solid was dissolved in Methanol became a light yellow liquid, which was dropped into diethyl ether to separate out white powder, which was uniformly sonicated and left to stand, repeatedly washed with methanol and diethyl ether, kept in refrigerator, and the solvent was removed in vacuo to obtain a white powder cyclodimethylene bis-1-(2, 4,6-Trimethylphenyl)-imidazole 640 mg (84%);

[0062] (2) Preparation of binuclea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com