Bee venom peptide and separation and purification method thereof

A technology for separation and purification of melittin, applied in the biological field, can solve the problems of high reagent consumption cost, harsh purification conditions, low separation purity, etc., and achieve the effects of less loss of target substances, high separation purity, and simple purification steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Solvent extraction

[0055] The crude bee venom was mixed according to the material-to-liquid ratio (crude bee venom: acetonitrile water extractant) 1g:1mL. Specifically, add 20% acetonitrile water extractant to the centrifuge tube, add crude bee venom to the 20% acetonitrile water extractant, vortex for 25min, centrifuge at 14000rpm for 20 minutes at 4°C, and take the supernatant. Repeat the vortex centrifugation step above and pool the supernatants.

[0056] (2) The first separation and purification of melittin

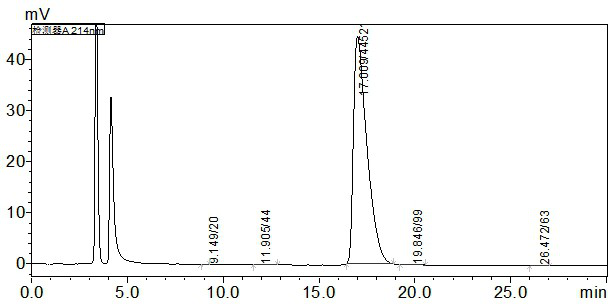

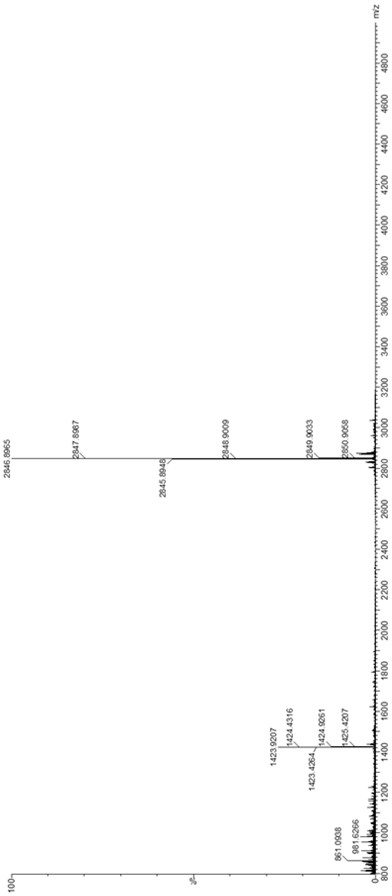

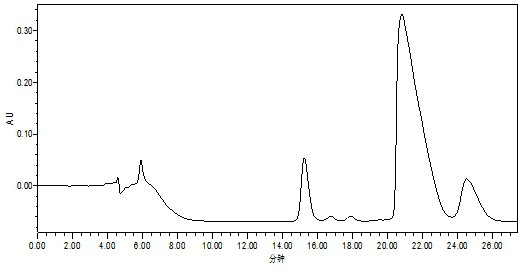

[0057] The supernatant was separated by reverse-phase C18 semi-preparative column, and 0.2% (volume percent) formic acid aqueous solution and acetonitrile system were used for gradient elution. The elution procedure was shown in Table 1. figure 1 The retention time is in the range of 14min-15min, and it is freeze-dried at low temperature to obtain melittin in white powder with a chromatographic purity greater than 90%, such as figure 2 shown.

[0058...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com