Preparation method and application of core-shell petal-shaped nickel-cobalt-phosphorus coated silver nanowire electro-catalysis electrode material

A technology of silver nanowires and catalytic electrodes, applied in electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of no oxygen evolution performance research and poor oxygen evolution activity, achieve excellent catalytic activity, reduce electron transfer resistance, and good The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

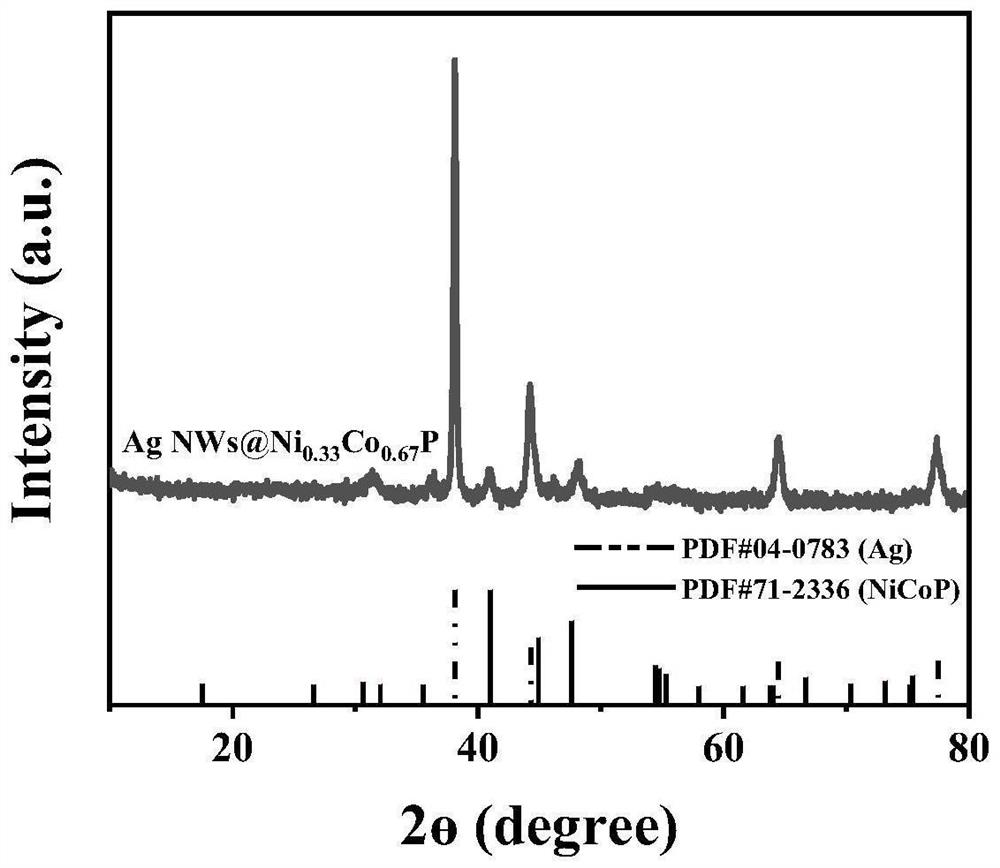

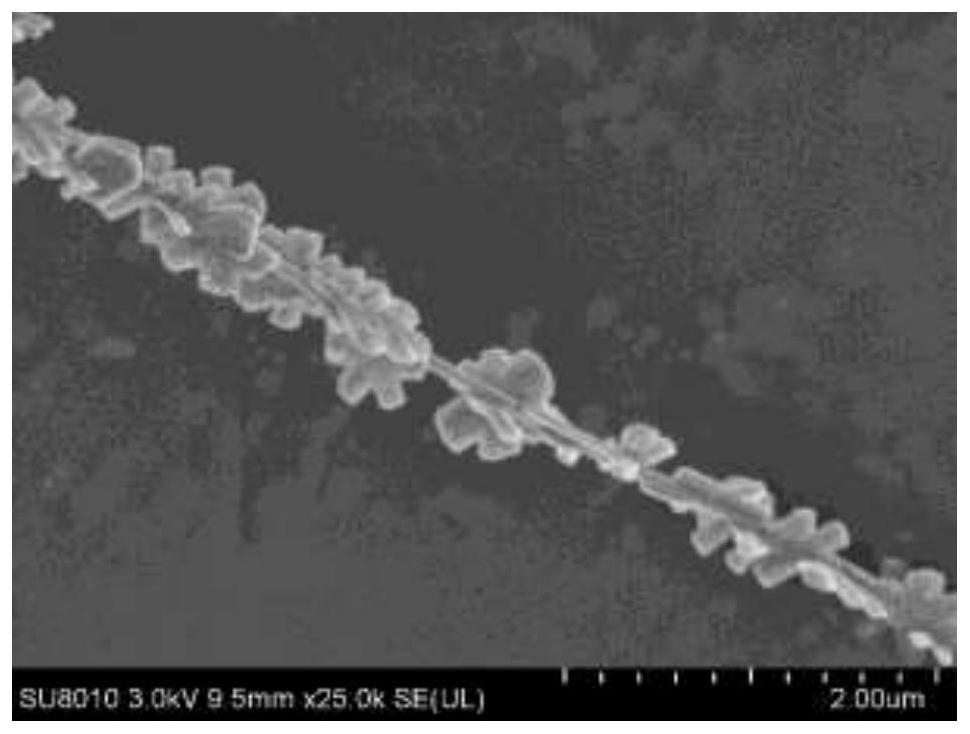

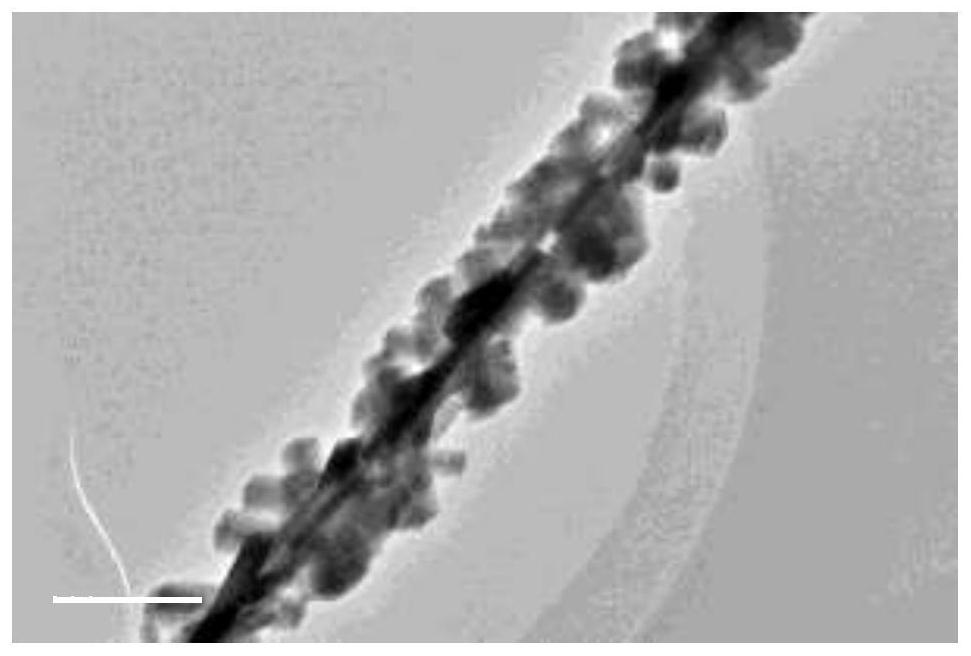

[0073] Embodiment 1. A three-dimensional core-shell petal-shaped nickel-cobalt-phosphorus-coated silver nanowire electrocatalytic electrode material, the preparation steps are as follows:

[0074] S1. Add 2 mL of silver nanowires (Ag NWs) with a mass fraction of 2% into a beaker containing 25 mL of deionized water, and sonicate at room temperature to uniformly disperse to obtain a silver nanowire dispersion with a mass fraction of about 0.15%.

[0075] S2, successively adding 0.33mmol nickel nitrate, 0.67mmol cobalt nitrate, 2mmol ammonium fluoride, 4mmol urea into the silver nanowire dispersion liquid of S1 gained, stirring at room temperature to above-mentioned 4 all dissolve;

[0076] S3. Transfer the solution obtained by stirring S2 into a stainless steel reaction kettle lined with polytetrafluoroethylene, and then transfer the reaction kettle to a high-temperature oven for hydrothermal reaction at 120 ° C for 6 hours; after the reaction is completed, the oven is cooled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com