Lining paper for cigarettes as well as manufacturing method and application of lining paper

A technology for cigarette inner lining paper and manufacturing method, which is applied in the directions of papermaking, paper, wrapping paper, etc., can solve the problems of not meeting development requirements, unable to be melted for recycling, and adding coating and drying processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a method for manufacturing a cigarette inner lining paper with functions of moisturizing, moisturizing and maintaining fragrance. The specific steps are as follows:

[0037] S1. Mix bleached kraft softwood pulp and bleached kraft hardwood pulp according to a mass percentage of 25%: 75%, and disintegrate into pulp with a mass concentration of 11%, further dilute to a mass concentration of 4.5%, and refine the pulp Treatment, so that the Shore freeness of the pulp is controlled at 35°SR;

[0038]S2. Preparation of chemical additives: fully dissolve the anionic polyacrylamide dispersant with water at a concentration of 0.03%; dilute the AKD emulsion of the sizing agent three times with water for use; use green inorganic pigments and blue inorganic pigments for coloring Dissolve them in water to a concentration of 1% for use;

[0039] S3. Preparation of calcium chloride modified iron silicate:

[0040] (1) adding water with technical grade ...

Embodiment 2

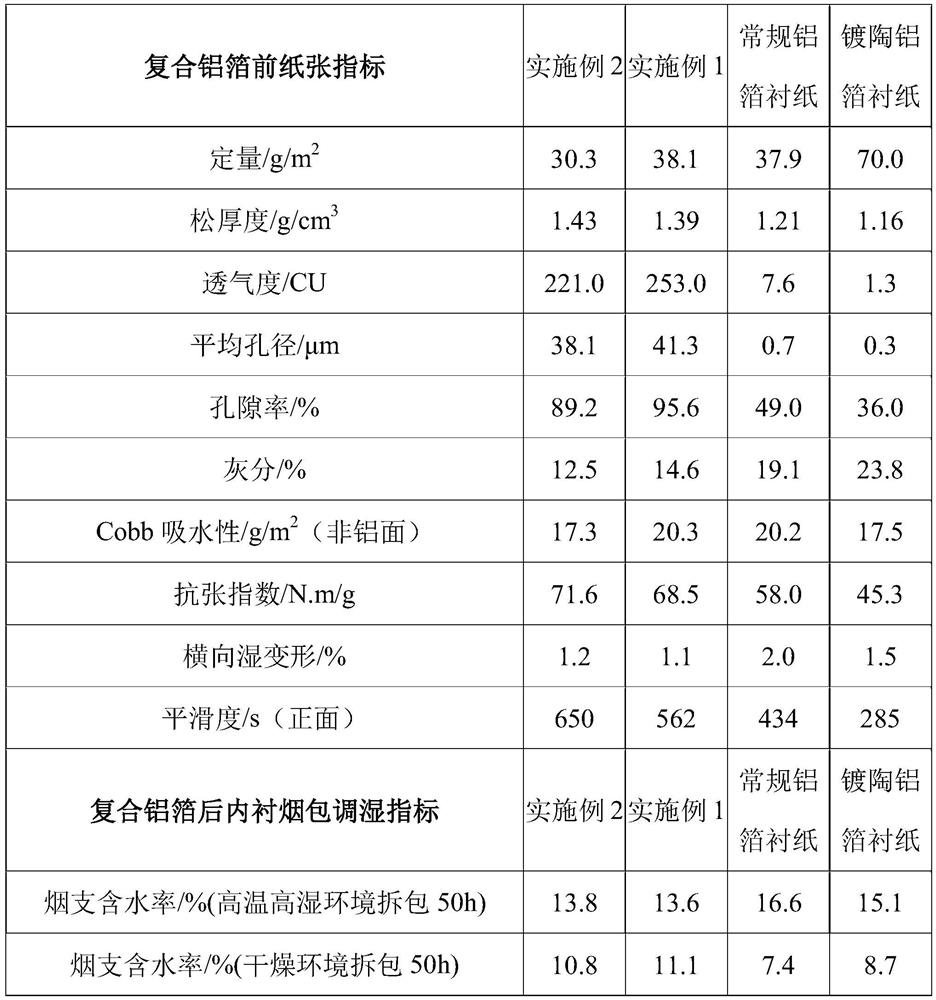

[0056] The present embodiment provides a method for manufacturing a cigarette lining paper with functions of moisturizing, moisturizing and maintaining fragrance. %: mixed with 70%, disintegrated into pulp with a mass concentration of 10%, diluted to a mass concentration of 4.0% for refining, and the beating degree is controlled at 50°SR; the absolute dry addition amount of modified iron silicate and diatomite is 200kg / ton of dry pulp, add 1.4kg blue inorganic pigment solution and 4.2kg green inorganic pigment solution per ton of dry pulp; use white water under the net to dilute the slurry to 0.5%; dilute the water main pipe in the headbox The pulp was diluted to a concentration of 0.20% with water; the addition of AKD stock solution was 2.0%; the dry addition of dispersant was 0.6%; the vehicle speed was 165m / min. The performance of the cigarette inner lining paper manufactured by the present embodiment is shown in Table 2:

[0057] The performance index of the cigarette i...

Embodiment 3

[0061] The present embodiment provides a method for manufacturing a cigarette inner lining paper with functions of moisturizing, moisturizing, and aroma. %: 80% mixed, crushed into pulp with a mass concentration of 12%, diluted to a mass concentration of 5.0% for refining, and the beating degree is controlled at 20°SR; the absolute dry addition amount of iron silicate and diatomite is 280kg / ton For absolute dry pulp, add 1.6kg of blue inorganic pigment solution and 4.8kg of green inorganic pigment solution per ton of absolute dry pulp; use white water under the net to dilute the pulp to 0.7%; the water from the dilution water main pipe in the headbox Dilute the pulp to a concentration of 0.30%; the addition amount of AKD stock solution is 1.0%; the absolute dry addition amount of dispersant is 0.2%; the vehicle speed is 145m / min. The performance of the cigarette inner lining paper manufactured by the present embodiment is shown in Table 3:

[0062] The performance index of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com