Preparation method and application of film with photonic device structure

A technology of photonic devices and thin films, applied in optical components, coupling of optical waveguides, instruments, etc., can solve problems such as high cost, limited application, complicated process, etc., and achieve the effects of low optical loss, fast response, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

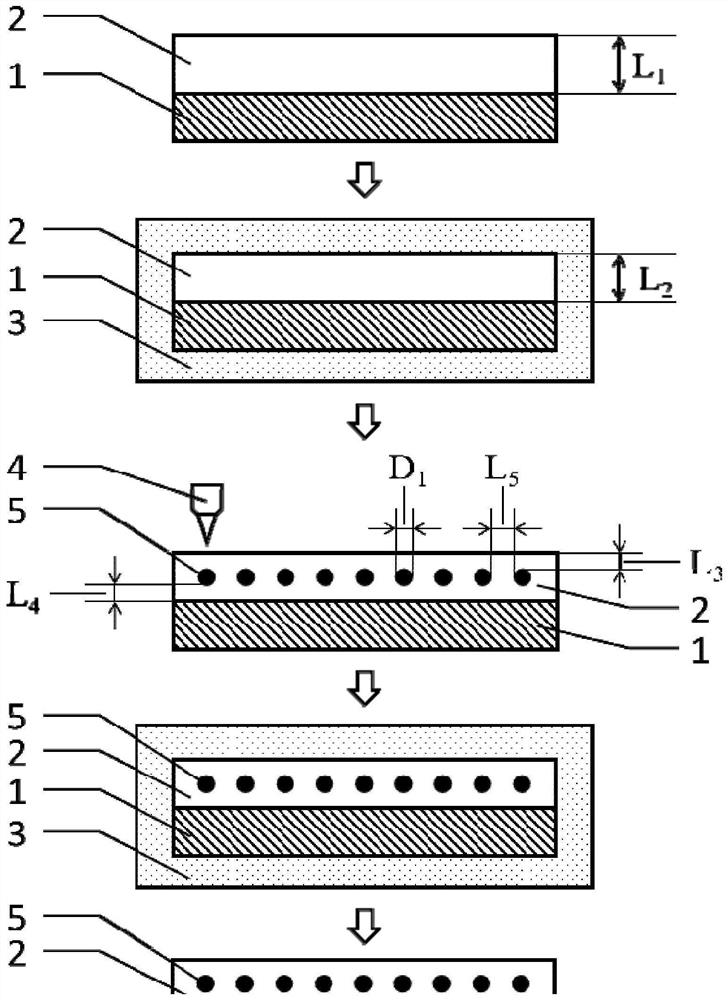

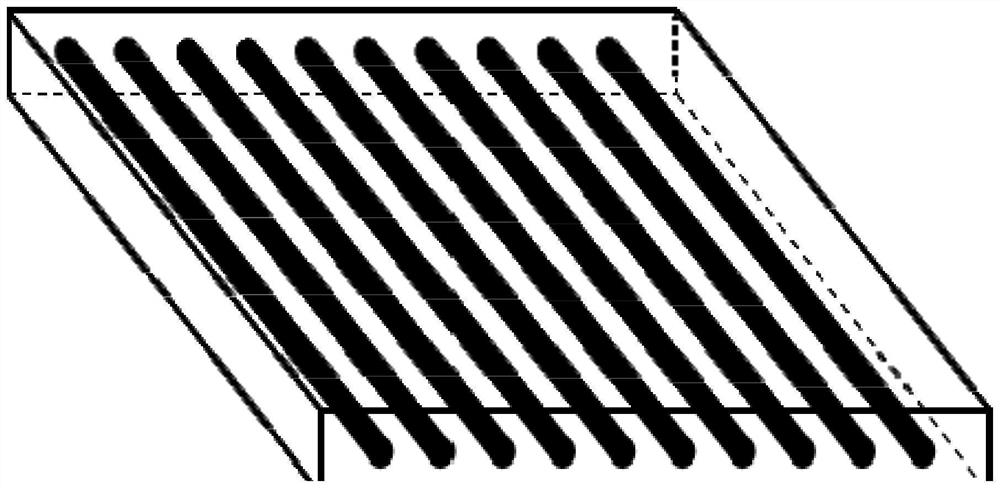

Method used

Image

Examples

Embodiment 1

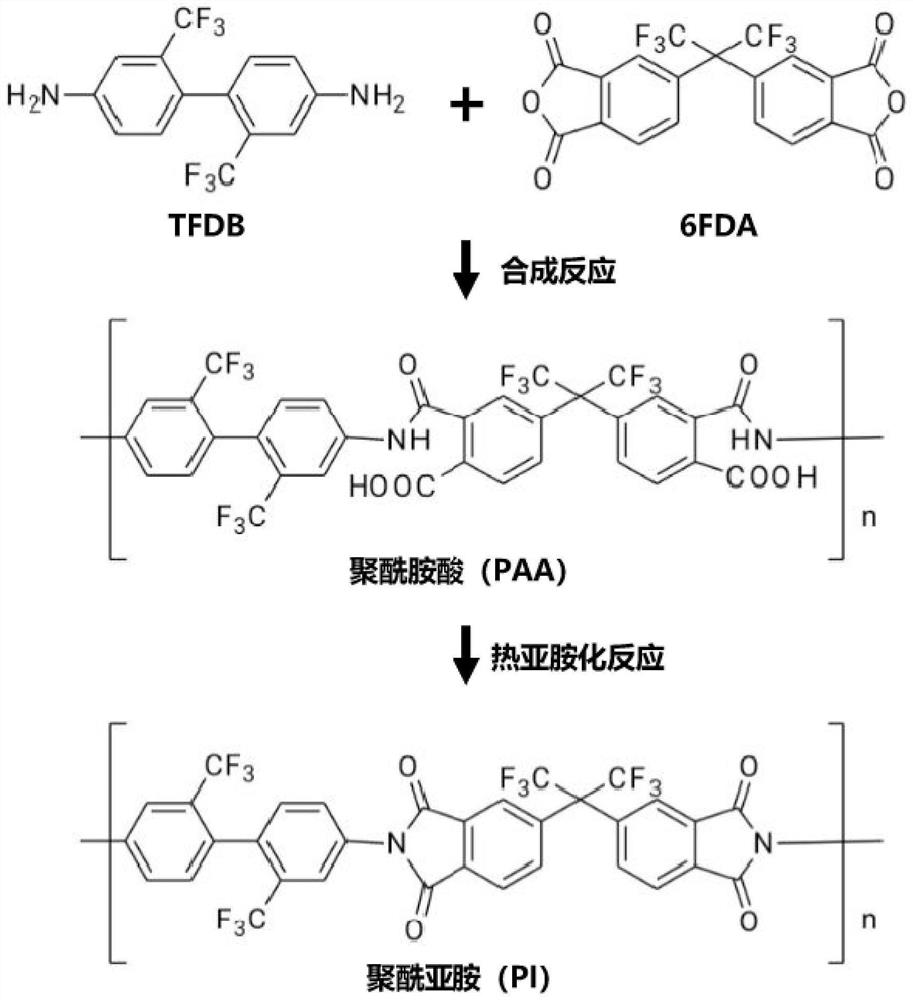

[0055] Synthesis of polyamic acid:

[0056] (1) in the three-necked flask, add anhydrous solvent DMAC 50mL, then weigh 5g of TFDB and add the solvent, under nitrogen protection, mechanically stir at a speed of 100 rev / min until dissolved to obtain a colorless transparent solution;

[0057] (2) Weigh 6FDA 6.93g, add the transparent solution of TFDB in 5 times, after the last addition in the process, under nitrogen protection, mechanically stir at a speed of 100 rpm until the dissolution is complete, and then repeat the operation to carry out the following Join at a time until all joins are completed at the end;

[0058] (3) after the addition of (2) is completed, after the solution is clarified, the rotating speed is increased to 300 rpm, and at 25 ° C, the reaction is performed for 22 hours, and finally PAA (polyamic acid) is obtained;

[0059] (4) Transfer the PAA into a clean glass bottle and store in a refrigerator at 5°C for later use.

[0060] Preparation of polyimide f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com