Organic porous material for electronic special gas separation and purification and preparation method thereof

A technology for separation and purification of porous materials, applied in the field of organic porous materials for separation and purification of electronic special gases and its preparation, to achieve good chemical stability, inhibition of adsorption and diffusion, and high-efficiency adsorption and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

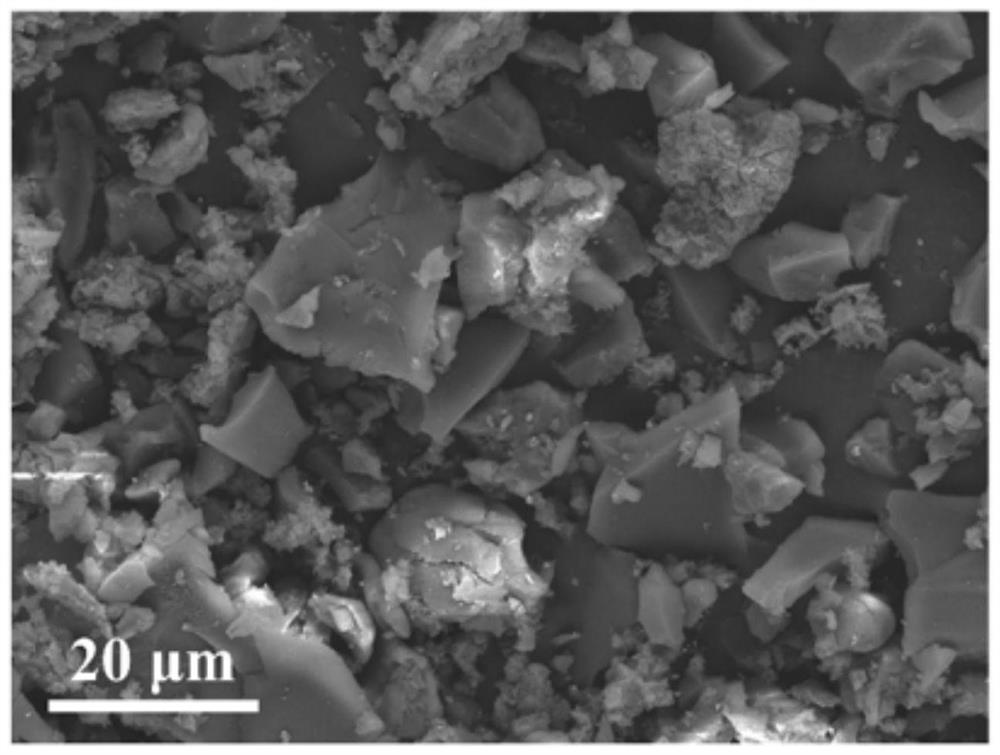

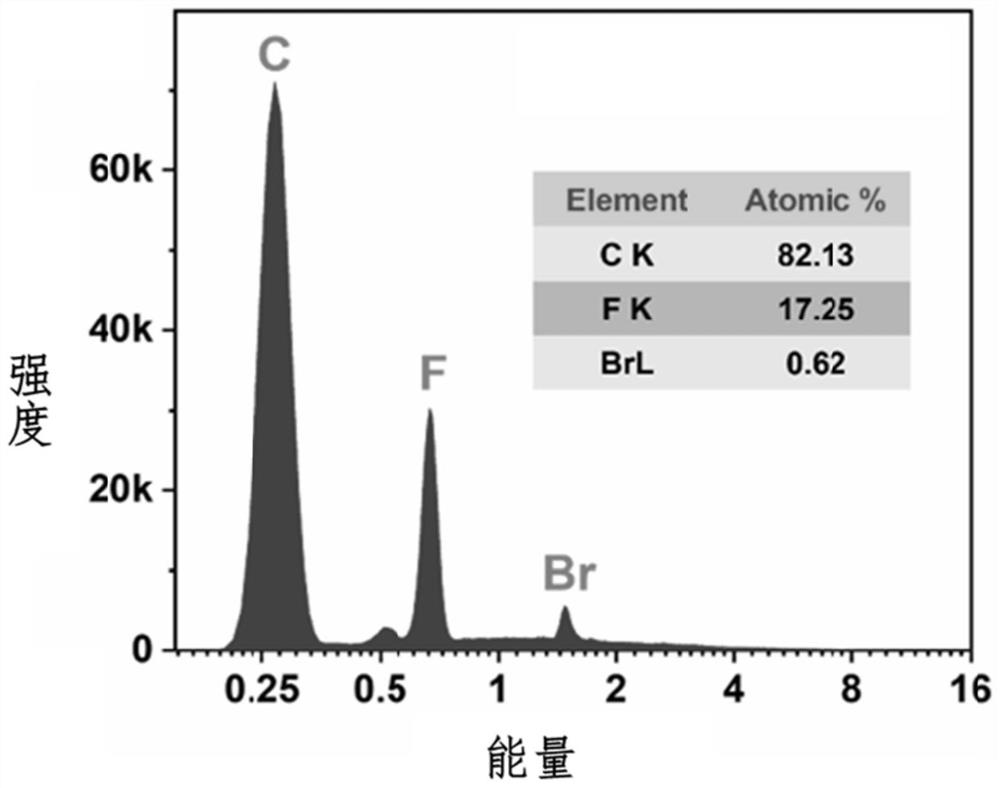

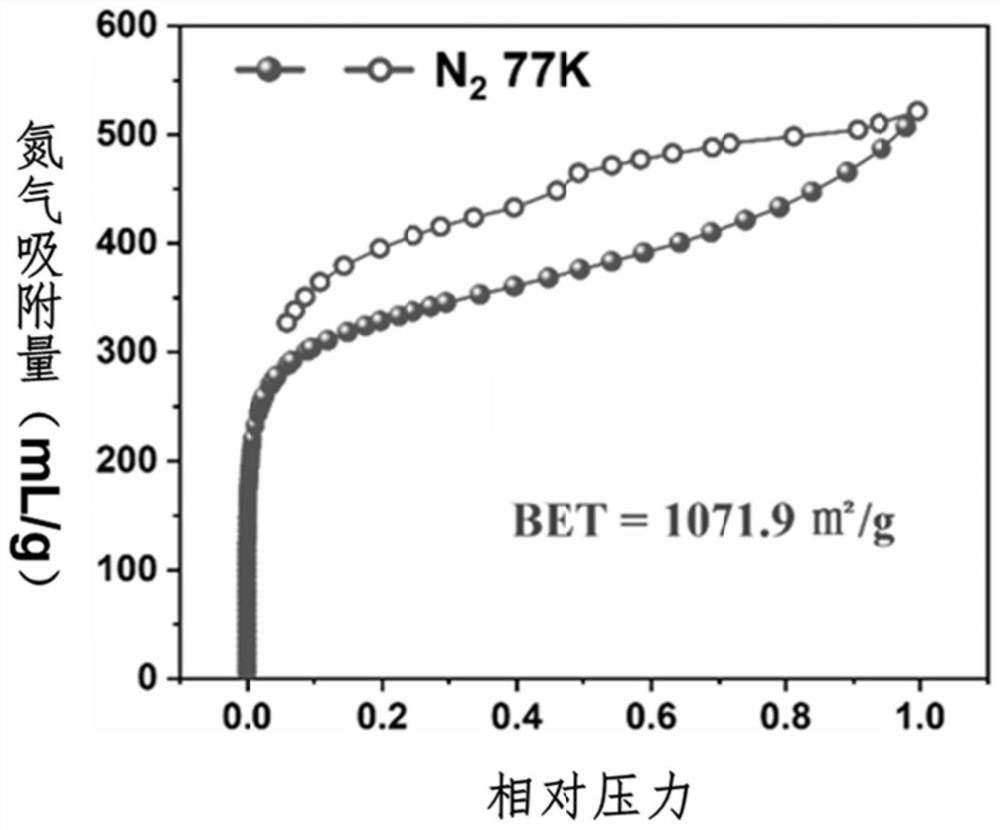

[0045] Step 1: In the 10L reaction kettle, weigh 1mol of tetrabromotetraphenylmethane and 2mol of 1,2,4,5 tetrafluorobenzene and add it, then add 0.1mol of palladium acetate, 0.2mol of tri-tert-butylphosphine tetrafluoroborate and 6LDMF, the materials are shaken and mixed evenly, after the nitrogen protection is completed, the temperature is set to 120 ° C, and the mixture is obtained by heating for 48 hours;

[0046] Step 2: Cool the mixture obtained in step 1 to room temperature, pour it into a material bucket, perform suction filtration on the obtained mixture, use DMF and methanol as washing solvents, and wash three times each to obtain a filter cake. Put the filter cake into a beaker containing DMF solution, rotate and stir on a magnetic stirrer for 1 h, and then perform suction filtration. The obtained product was subjected to Soxhlet extraction with ethanol reagent for 24 hours to further remove impurities, and the solid extracted by Soxhlet was vacuum-dried at 150° C. ...

Embodiment 2

[0052] Step 1: In the 10L reaction kettle, weigh 1mol of tetrabromotetraphenylmethane and 2mol of 1,2,4,5 tetrafluorobenzene and add it, then add 0.1mol of palladium acetate, 0.2mol of tri-tert-butylphosphine tetrafluoroborate With 6L nitrogen methyl pyrrolidone, the materials are shaken and mixed evenly, after nitrogen protection is completed, the temperature is set to 150 ° C, and heated for 48 hours to obtain a mixed solution;

[0053] Step 2: Cool the mixture obtained in step 1 to room temperature, pour it into a material bucket, perform suction filtration on the obtained mixture, use ethanol and methanol as washing solvents, and wash three times each to obtain a filter cake. Put the filter cake into a beaker containing DMF solution, rotate and stir on a magnetic stirrer for 1 h, and then perform suction filtration. The obtained product was subjected to Soxhlet extraction with ethanol reagent for 24 hours to further remove impurities, and the solid extracted by Soxhlet was...

Embodiment 3

[0063] Step 1: In the 10L reaction kettle, weigh 1mol of tetrabromotetraphenylmethane and 2mol of 1,2,4,5 tetrafluorobenzene and add it, then add 0.1mol of palladium acetate, 0.2mol of tri-tert-butylphosphine tetrafluoroborate and 6L nitrogen methyl pyrrolidone, the materials are shaken and mixed evenly, after nitrogen protection is completed, the temperature is set to 130 ° C, and heated for 48 hours to obtain a mixed solution;

[0064] Step 2: Cool the mixture obtained in step 1 to room temperature, pour it into a material bucket, perform suction filtration on the obtained mixture, use methanol as a rinsing solvent, and rinse three times to obtain a filter cake. Put the filter cake into a beaker containing DMF solution, rotate and stir on a magnetic stirrer for 1 h, and then perform suction filtration. The obtained product was then subjected to Soxhlet extraction with ethanol reagent for 24 hours to further remove impurities, and the solid extracted by Soxhlet was vacuum-dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com