Production device and production process for extracting lithium from brine through efficient adsorption method

A production device and adsorption method technology, which are applied in selective adsorption, ion exchange treatment device, solid adsorbent liquid separation, etc., to achieve the effects of low risk, simple preparation method and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: 50,000 t / a lithium carbonate production

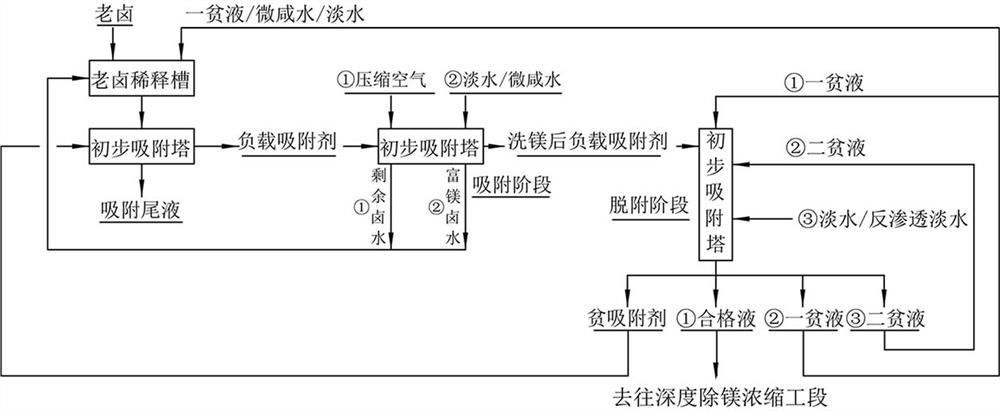

[0041] like Figure 1-3 As shown, a production device for extracting lithium from brine by an efficient adsorption method includes a preliminary adsorption and magnesium removal section, a deep magnesium removal and concentration section, and a precipitation lithium reaction section;

[0042] The preliminary adsorption and magnesium removal section includes: an old halogen dilution tank and a preliminary adsorption tower;

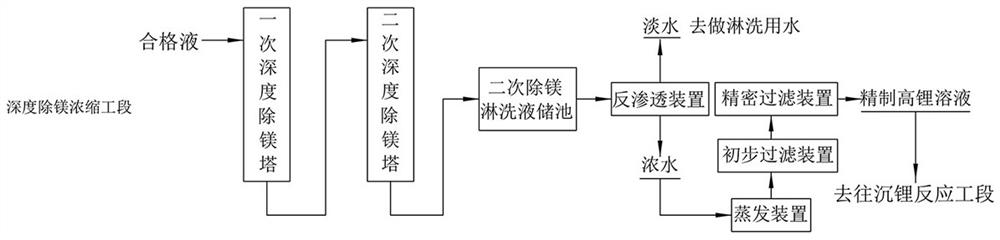

[0043] The deep magnesium removal and concentration section includes: a primary deep magnesium removal tower, a secondary deep magnesium removal tower, a secondary magnesium removal eluent storage tank, a reverse osmosis device, an evaporation device, a preliminary filter device, and a precision filter device;

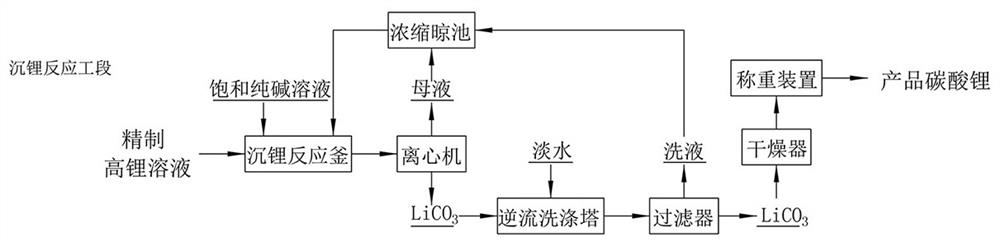

[0044] The lithium precipitation reaction section includes: a precipitation lithium reaction kettle, a centrifuge, a concentration drying tank, a countercurrent washing tower, a filter, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com