Double-antibody material and preparation method thereof

A technology of raw materials and antistatic agents, which is applied in the field of double antistatic materials and their preparation, can solve the problems of damaging the physical properties of materials, affecting the mechanical properties of materials, and affecting the physical properties of materials, so as to achieve increased compatibility, high mechanical properties, and no The effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

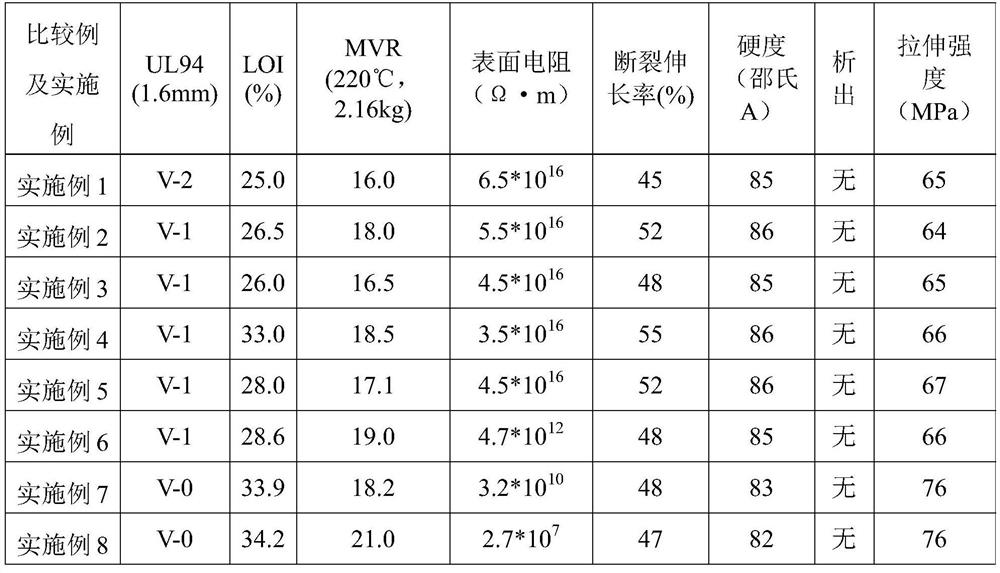

Examples

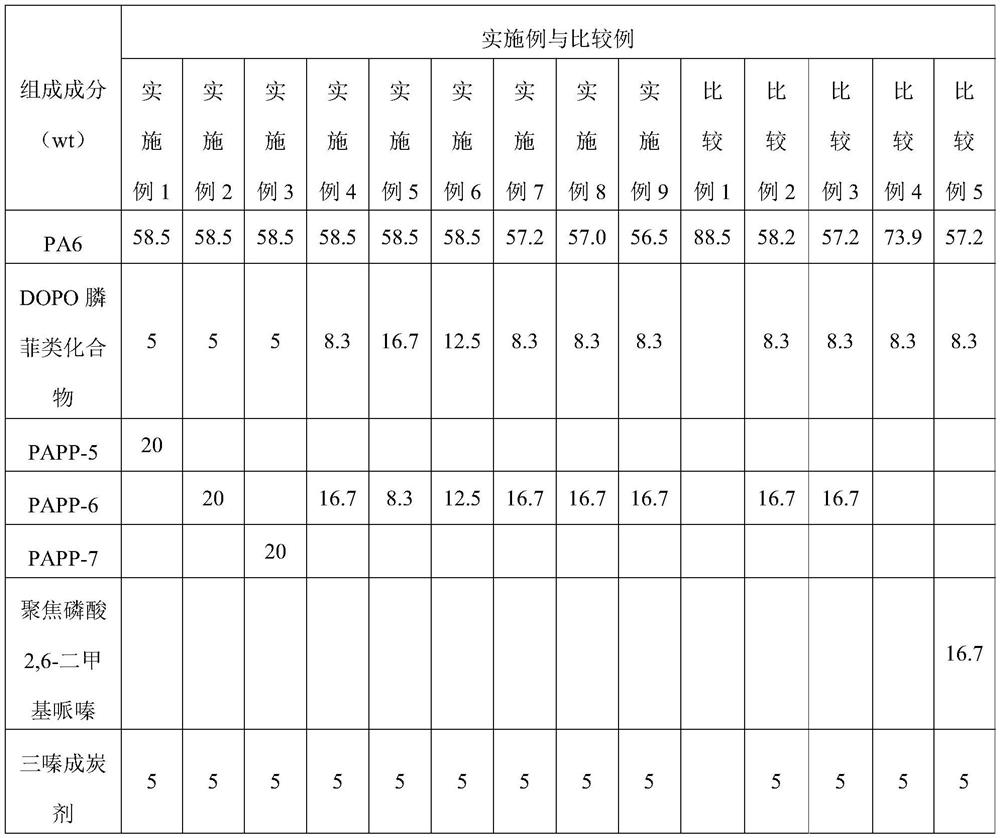

Embodiment 1

[0071] 1) By weight, 5 parts of DOPO phosphine phenanthrene compounds, 20 parts of PAPP-5, 5 parts of triazine carbon-forming agent, 10 parts of wollastonite, 0.5 part of antioxidant 1010, 0.5 part of phenyl salicylate, 0.5 part of ethylene bis-stearoyl was added into a high-speed mixer for high-speed pre-mixing to obtain a mixture. The rotational speed of the blades was 200 rpm, the mixing time was 3 minutes, the inclination angle of the body was 0°, and the staggered angle of the blades was 45°. Subsequently, 58.5 parts of nylon was added to the above mixture, and mixed at high speed for 2 min to obtain a mixture.

[0072] 2) The stirred mixture is placed in the feeding section of the twin-screw extruder, and after the material is extruded by screw mixing, it is extruded from the die; the temperature of the first to fifth sections of the twin-screw extruder is once : 180°C, 200°C, 220°C, 220°C, 220°C; the speed of the main engine of the twin-screw extruder is 220r / min; the f...

Embodiment 10-14

[0083] Compared with Example 7, most of them are the same, except that the nylon in this example is adjusted to PA66, PA56, PA9T, PA10T, PA6T of equal weight, respectively.

Embodiment 15-21

[0085] Compared with Example 7, most of them are the same, except that the antioxidants in this example are adjusted to equal weights of 2,6 di-tert-butyl-p-cresol, 1,1,3 tris(2-methyl) respectively. -4Hydroxy-5-tert-butylphenyl)butane, 2,2'-methylenebis(4-ethyl-6-tert-butylphenol), 1,3,5-tris(3,5tert-butyl- 4-Hydroxybenzyl)trimethylbenzene, 2,2'-methylenebis(4-methyl-6-tert-butylphenol), 1,6hexamethylenebis(3,5di-tert-J- 4-Hydroxyphenyl)propionate, 4,4'-di-tert-octyldiphenylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com