Reaction-enhanced pre-paved waterproof coiled material and preparation method thereof

A waterproofing membrane, reaction enhancement technology, applied in the direction of adhesive types, building insulation materials, roofing using flexible materials, etc. The effect of improving waterproof safety, improving technical level, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of above-mentioned a kind of reaction-enhanced type pre-laid waterproof roll material, comprises the steps:

[0047] Step 1: prepare the modified epoxy resin by reacting rosin or hydrogenated rosin with epichlorohydrin;

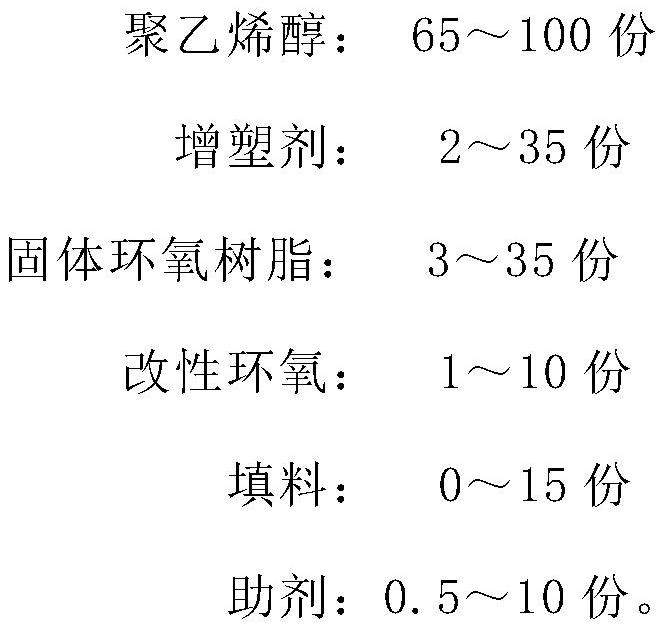

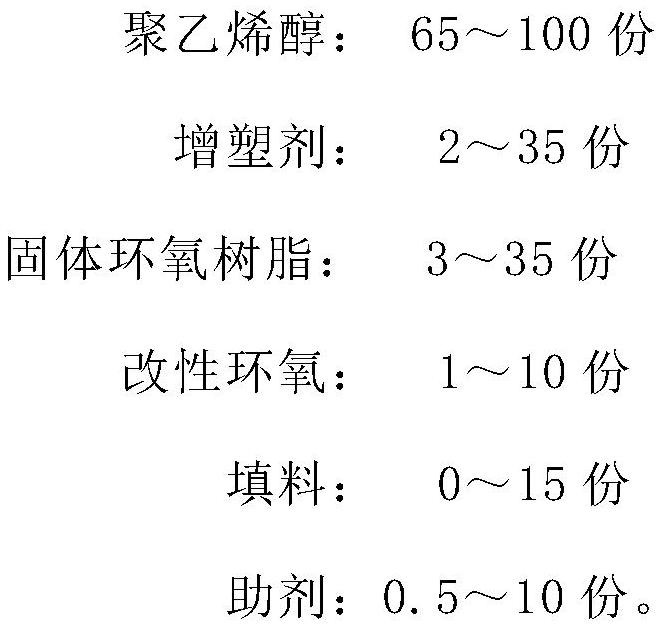

[0048] Step 2: blending the modified epoxy resin with polyvinyl alcohol, plasticizer, solid epoxy resin, filler and auxiliary agent to prepare a reactive reinforced bonding protective layer;

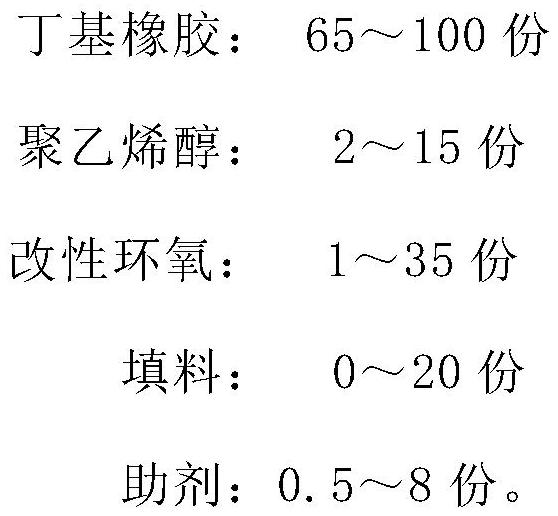

[0049] Step 3: blend the modified epoxy resin with butyl rubber, polyvinyl alcohol, filler and auxiliary agent to prepare an adhesive;

[0050] Step 4: composite the self-adhesive layer and the main material layer by dipping, scraping or hot pressing process to obtain a single-sided self-adhesive main material layer or a double-sided main material layer;

[0051] Step 5: Cover one side of the self-adhesive layer of the single-sided self-adhesive main material with an adhesive, and coat the adhesive with a reactive reinforced bonding protec...

Embodiment 1

[0071] Add epichlorohydrin to the hydrogenated rosin according to the mass ratio of 2.2:1, wherein the epichlorohydrin is slightly excessive, and stir at 95°C to fully dissolve the rosin; add 1.5% mass fraction of the rosin to the fully dissolved rosin. Tetrabutylammonium iodide, heated and stirred for 3 hours at 95°C, ended the reaction, and cooled to room temperature; then, water was added to fully wash the product, and the water-soluble catalyst tetrabutylammonium iodide was removed to obtain a water-containing intermediate product; A mixed solvent of dichloromethane / ethyl acetate / xylene with a volume ratio of 1:3:1 was added to the intermediate product of 1:3:1, and after mixing evenly, it was allowed to stand for 48 hours, and a liquid separation treatment was performed to remove excess water in the intermediate product. Under the condition of 80°C, the intermediate product containing dichloromethane / ethyl acetate / xylene was rotary evaporated, and the solvent and hydrogen ...

Embodiment 2

[0077] Add epichlorohydrin to the rosin according to the mass ratio of 2.5:1, wherein the epichlorohydrin is slightly excessive, and stir at 90°C to fully dissolve the rosin; add 1% mass fraction of tetrafluoroethylene to the fully dissolved rosin. Butylammonium bromide, heated and stirred for 5 hours at 95°C, ended the reaction, and cooled to room temperature; then, water was added to fully wash the product, and the water-soluble catalyst tetrabutylammonium bromide was removed to obtain a water-containing intermediate product; A mixed solvent of dichloromethane / xylene with a volume ratio of 1:4 was added to the intermediate product, and after mixing evenly, it was allowed to stand for 48 hours, and a liquid separation treatment was performed to remove excess water in the intermediate product. Under the condition of 70°C, the intermediate product containing dichloromethane / xylene solvent was rotary evaporated, and the solvent and hydrogen chloride were removed to obtain the ros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com