High-close-packing flexible anti-radiation pseudo-type glass cover plate and preparation method thereof

A cover glass and anti-irradiation technology, which is applied in the field of materials, can solve the problems of unfavorable scrape coating film uniformity, high structural requirements, and short operating time, so as to enhance anti-radiation performance, improve preparation efficiency, and improve The effect of translucency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

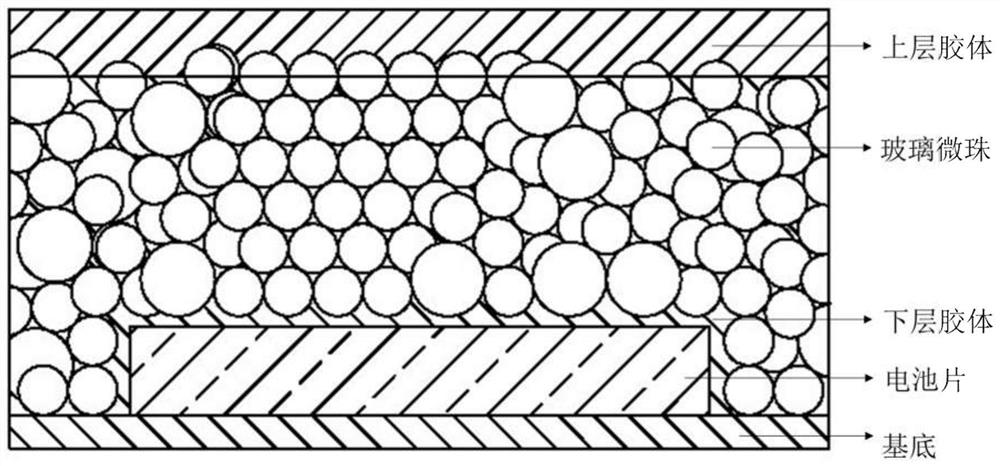

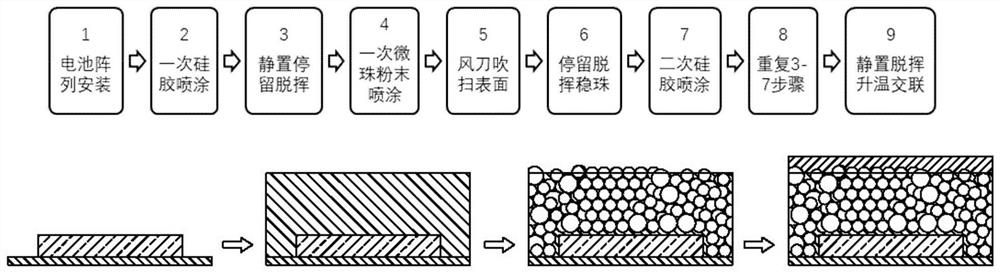

Method used

Image

Examples

Embodiment

[0063] Step 1: Silicone Rubber Spray

[0064] Use pneumatic compressed air to adjust the pressure of the spray gun between 0.1 and 8 bar. The spraying method can be manual spraying or automatic spraying mode, and the surface of the cell is sprayed with silicone rubber solution. Spraying method: 1. The battery is fixed, and the nozzle moves serpentinely along the X or Y direction alone and alternately sprays; 2. The battery substrate and the nozzle keep moving at the same time, and reciprocate relative to the X and Y axes for spraying. The moving speed of the nozzle is between 0.1 and 100 mm / s, and the moving speed of the cell substrate is between 0 and 100 mm / s. Control the thickness and uniformity of the silicone rubber sprayed in the moving direction. After the silicone rubber is sprayed, the temperature is controlled at 30-100°C in the fume hood, and the level is still for 5-60 minutes. When the battery surface solution is uniform and transparent, it is smoothed to the next...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com