Preparation method of diphosphorus ligand

A technology of phosphorus ligand and phosphorus pentachloride is applied in the field of preparation of double phosphorus ligands, and can solve the problems of complex process, high safety risk, difficult preservation and the like, and achieve the effects of easy control of process conditions, simple raw materials, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] In the traditional process of preparing chiral double phosphorus ligands, the process is complicated, such as the following preparation route process:

[0079]

[0080]

[0081]

[0082] In the above-mentioned preparation process, it is necessary to first use chiral diol as raw material thionyl chloride to react to obtain a sulfoxide compound, and then the sulfoxide compound is reacted with a phosphorus-hydrogen intermediate. However, the phosphorus-hydrogen bond is very sensitive to water in the air, and it is difficult to It has a bad odor and high safety risk, and the reaction conditions are relatively harsh, which is not conducive to large-scale production.

[0083] Based on this, the technical personnel of the present application propose to improve the above-mentioned synthetic route to obtain a synthetic route that is relatively simple and can be reacted under milder conditions. body preparation method.

[0084] An embodiment of the present invention pro...

Embodiment 1~4

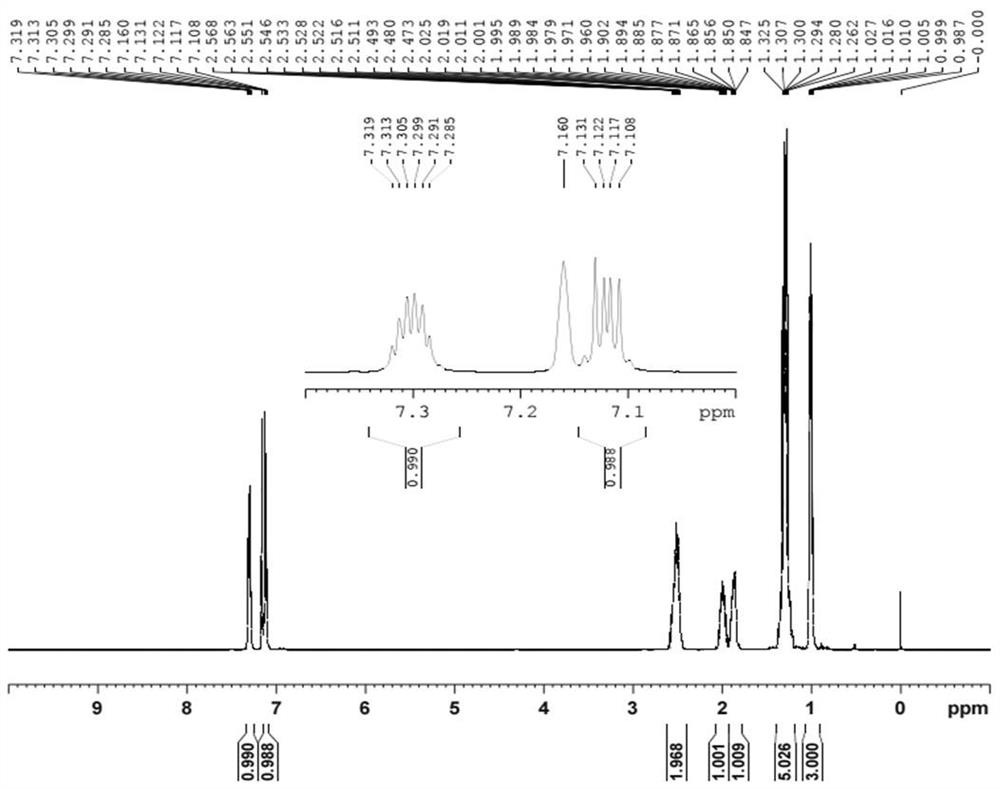

[0187] Compounds (1b) with different structures are synthesized in Examples 1 to 4, which are respectively denoted as compound (1b-1), compound (1b-2), compound (1b-3) and compound (1b-4). The structures are shown in Table 1. Show.

[0188] Specific steps are as follows:

[0189] The 3-L three-necked flask with the magneton was replaced three times with argon, then 1 mol of compound (1a) and methanol (1 L) were added, and cooled to 0°C under an ice-salt bath. Then, under stirring conditions, sodium borohydride (56 g, 1.5 mol) was added in batches, hydrogen was generated during the dropwise addition, and the temperature of the system was controlled not to be higher than 20 °C. After the dropwise addition, the reaction was stirred overnight, and then water (1 L ) to quench the reaction, spin dry methanol, extract with ethyl acetate (1 L×3), take the organic phase and wash with saturated brine, dry over anhydrous sodium sulfate, spin dry the solvent to obtain pure compound (1b)....

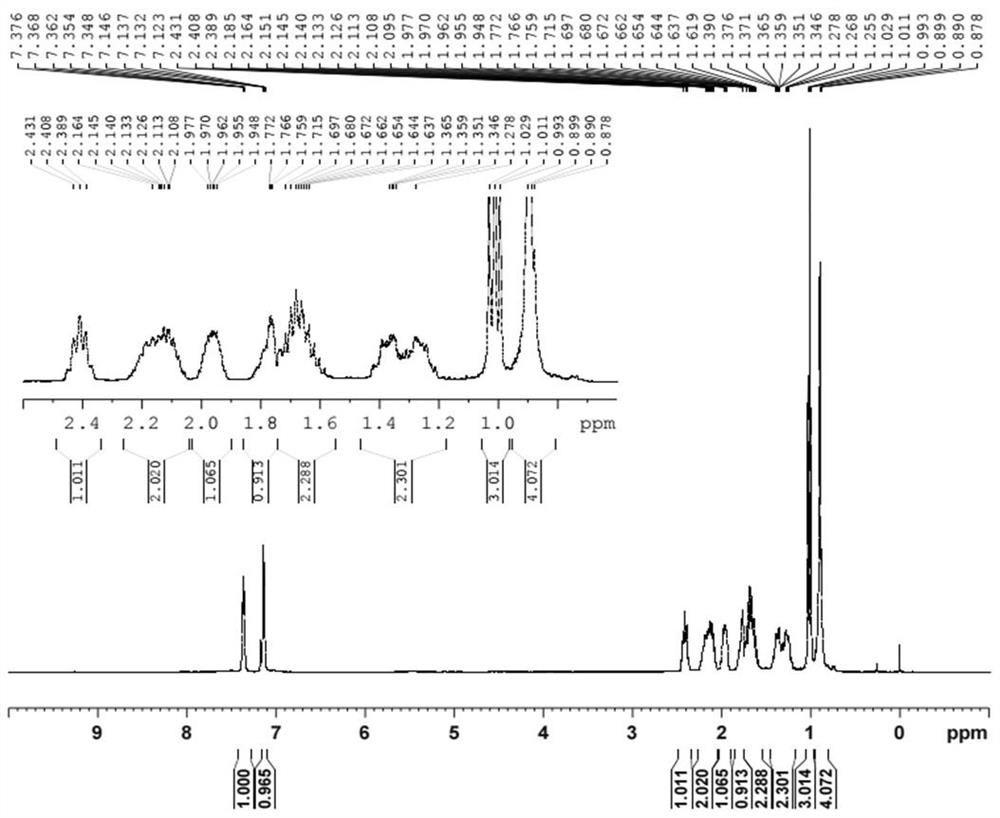

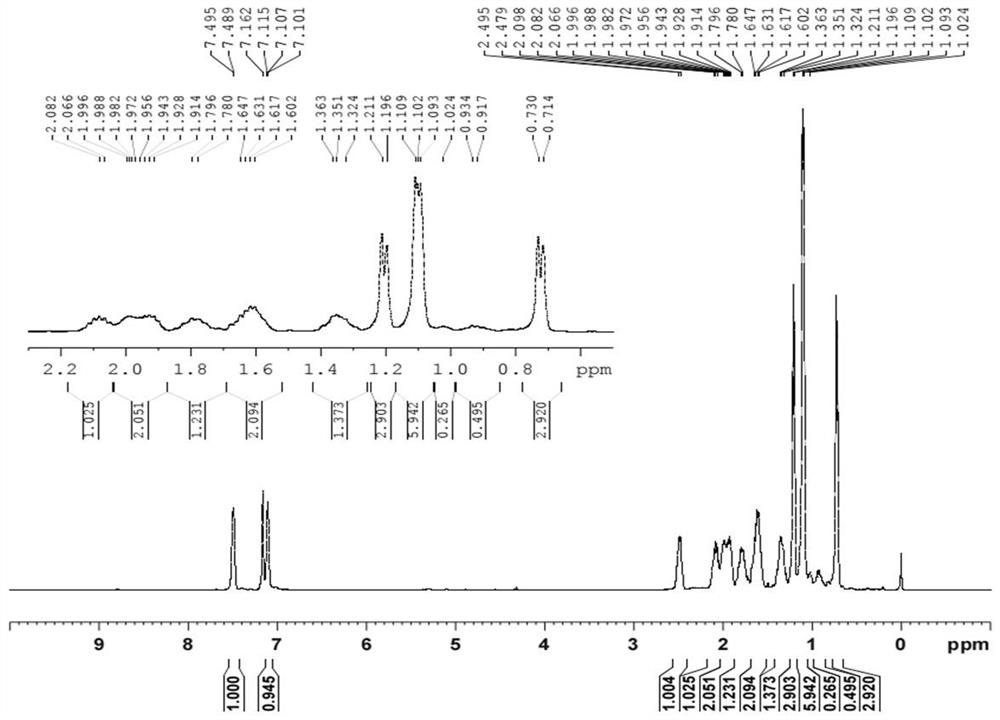

Embodiment 5~8

[0197] In Examples 5-8, the compounds (1b) prepared in Examples 1-4 were respectively used to prepare compound (1), and the prepared compounds (1) were denoted as compound (1-1), compound (1-2), compound (1-3) and compound (1-4). The specific steps are as follows: add 1 mol of compound (1b) to a 1 L there-necked flask with magnetic particles, cool to -5°C, and slowly add tribromide to the there-necked flask through a constant pressure dropping funnel under stirring conditions. Phosphorus (600 g, 1.2 mol), the temperature of the system was controlled not to be higher than 5 °C during the dropwise addition. After the dropwise addition, the reaction temperature was gradually raised to room temperature, and the reaction was stirred overnight, and then the reaction solution was poured into 1 L of ice water , the organic phase was washed with 96% concentrated sulfuric acid, water, saturated sodium carbonate and brine respectively, dried over anhydrous sodium sulfate, and then collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com