Mg/Zn-MOF-74-coated Fe3O4 magnetic composite material and application thereof in aflatoxin enrichment

A magnetic composite material and aflatoxin technology, which is applied in the field of magnetic nanomaterials and food safety, can solve the problems of low adsorption efficiency, slow extraction speed, and high cost of use, and achieve the effect of less reagents, low cost, and high pretreatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Example 1 A kind of preparation of Mg / Zn-MOF-74@Fe 3 O 4 Methods

[0106] (1) Fe 3 O 4 Preparation of Magnetic Nanoparticles

[0107] FeCl 3 ·6H 2 O (10.0 mmol) and NaAc (4.0 mmol) were added to 25 mL of ethylene glycol (50 mL beaker for easy stirring), followed by 3.0 mmol of SDS and magnetic stirring at 400 r / min for 15-30 min. The yellow transparent mixed solution was then transferred to a 50 mL synthesis vessel and heated at 220 °C for 10 h. After cooling to room temperature, Fe was separated by magnetic separation 3 O 4 The black precipitate was separated from the remaining solution, and the resulting Fe was subsequently washed repeatedly with deionized water and absolute ethanol. 3 O 4 Magnetic nanoparticles until the supernatant is neutral. Finally, the prepared magnetic nanoparticles were placed in a vacuum drying oven and vacuum-dried at 80 °C for 2.5 h to obtain Fe with superparamagnetic properties. 3 O 4 Magnetic nanoparticles were stored at 4°C ...

Embodiment 2

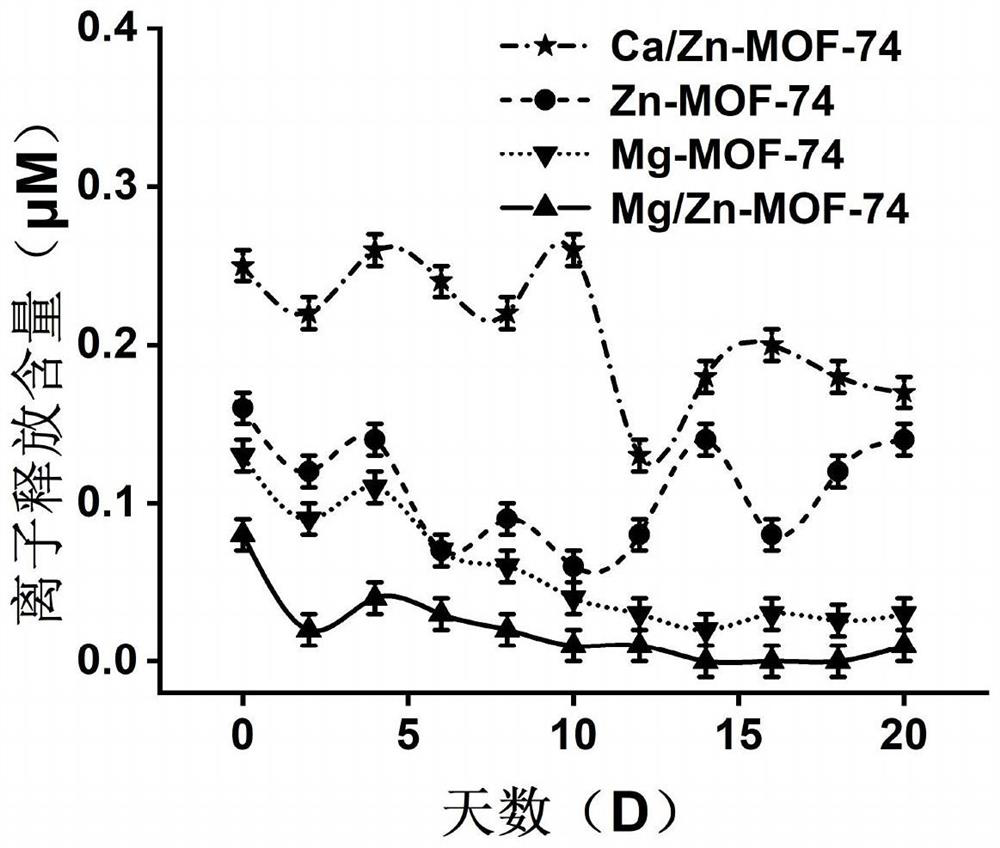

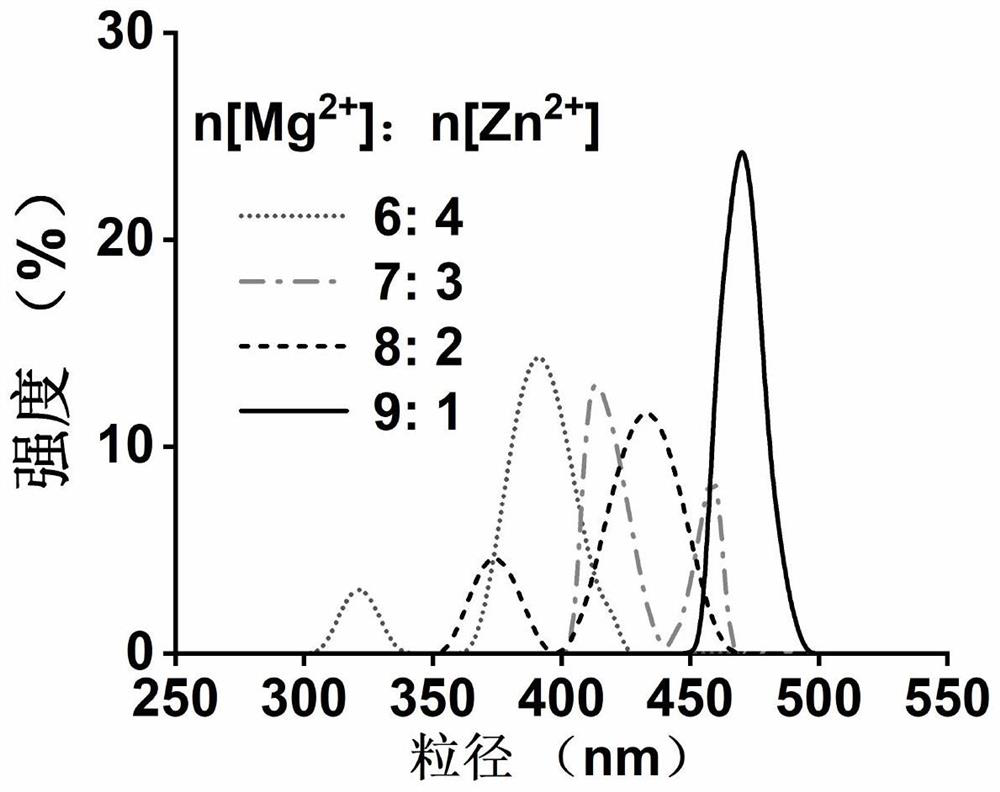

[0112] Example 2 Selection and Optimization of Synthetic Raw Materials

[0113] (1) Prepare Fe according to the step (1) of Example 1 3 O 4 magnetic nanoparticles;

[0114] (2) prepare Mg / Zn-MOF-74 by step (2) of embodiment 1;

[0115]Preparation of Mg-MOF-74: The pretreated titanium sheet was immersed in 1 mL of 0.1 mol / L Mg(NO) 3 ) 2 ·6H 2 O1h. After the reaction was completed, titanium flakes, 0.3 mmol DHTA and 5 mL DMF were added to a polytetrafluoroethylene reactor (microwave assisted heating), and heated at 130° C. for 24 h. The titanium sheet pretreatment method and the cleaning and drying method of Mg-MOF-74 are consistent with step (2) of Example 1.

[0116] Preparation of Zn-MOF-74: The pretreated titanium sheet, 0.3 mmol DHTA, 1 mmol Zn(NO 3 ) 2 ·6H 2 O and 15 mL of DMF were added to the Teflon reactor (microwave assisted heating) and heated at 130 °C for 24 h. The titanium sheet pretreatment method and the cleaning and drying method of Zn-MOF-74 are cons...

Embodiment 3

[0125] Example 3 Mg / Zn-MOF-74@Fe 3 O 4 Structural characterization of

[0126] Prepare Mg / Zn-MOF-74@Fe by the method of Example 1 3 O 4 .

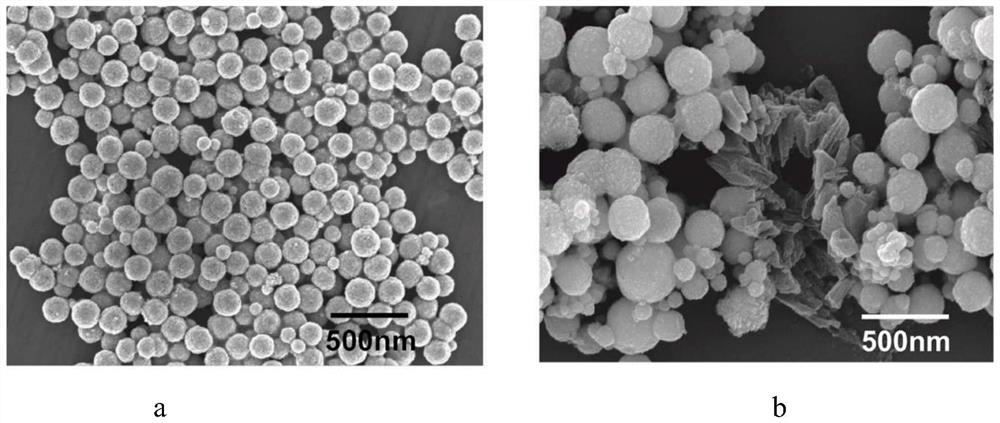

[0127] (1) Characterization by scanning electron microscope (SEM)

[0128] image 3 for Fe 3 O 4 and Mg / Zn-MOF-74@Fe 3 O 4 scanning electron microscope image. like image 3 shown, Fe 3 O 4 The cross-linking and bonding between the nanoparticles and the Mg / Zn-MOF-74 metal framework formed a clear regular hexagonal cluster structure with a size of about 380-480 nm. The size of the regular hexagonal cluster structure in each region is different, which is presumed to be obvious crystal growth during the high-temperature synthesis process. The above electron microscope directly proves that Mg / Zn-MOF-74@Fe 3 O 4 Synthesis. This shows that Fe 3 O 4 The nanoparticles were successfully incorporated into the Mg / Zn-MOF-74 metal framework.

[0129] (2) Energy Dispersion (EDS) Characterization

[0130] Table 2 shows Mg / Zn-MOF-74@Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com