Alpha-calcium sulfate hemihydrate crystal whisker with high length-diameter ratio as well as preparation method and application of alpha-calcium sulfate hemihydrate crystal whisker

A technology of calcium sulfate hemihydrate and high aspect ratio, applied in the field of materials engineering, can solve the problems of short whiskers and limited application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

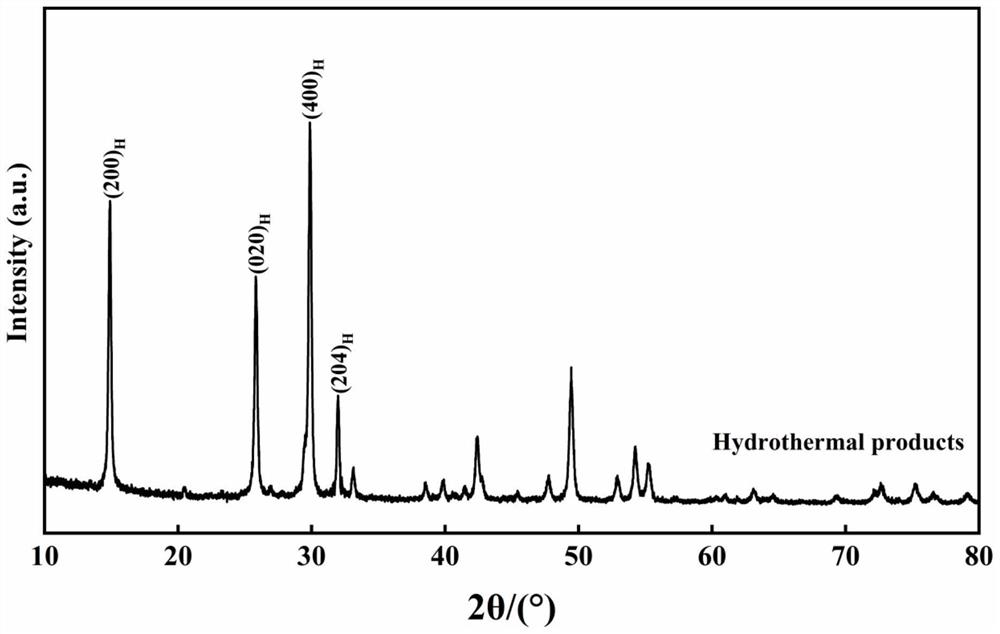

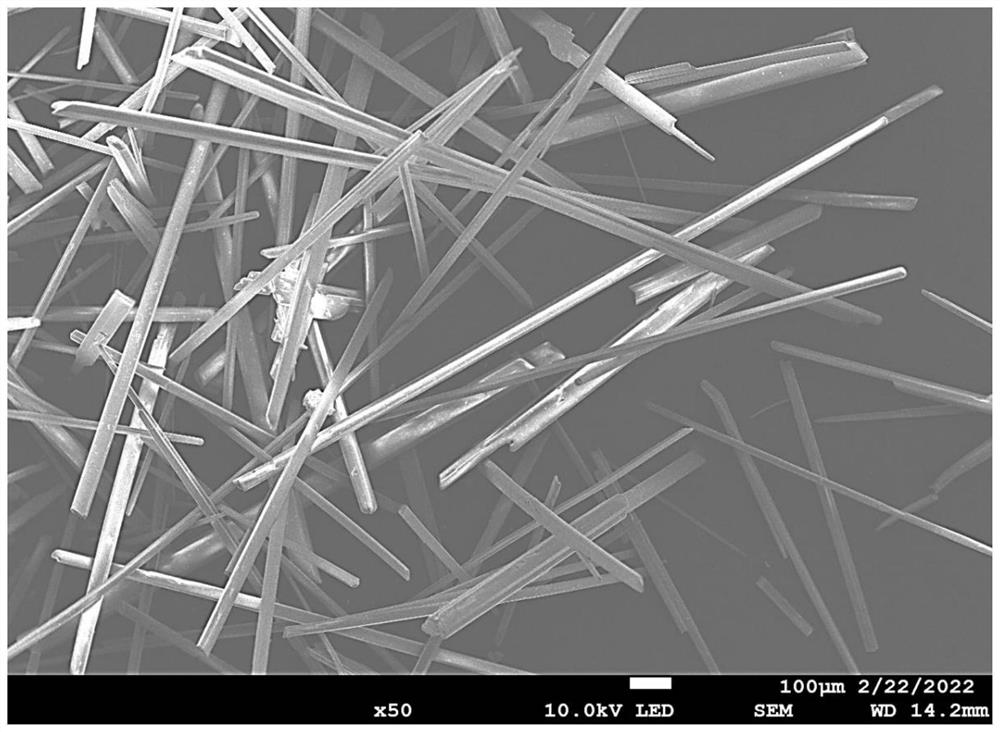

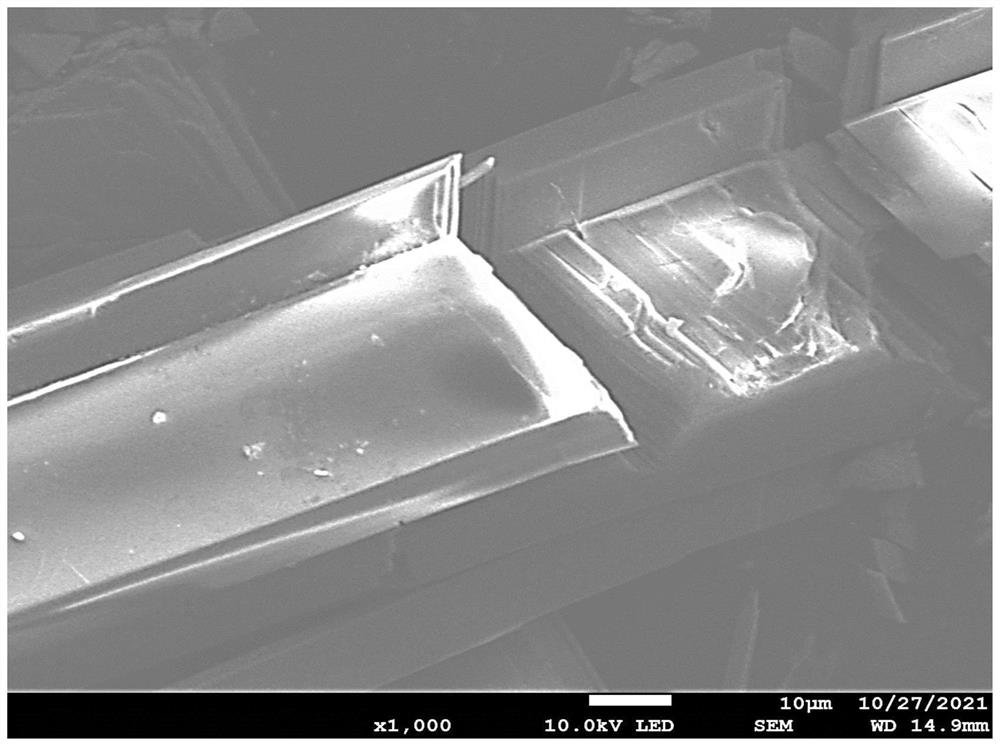

[0020] Some embodiments of the present invention provide a method for preparing high aspect ratio α-calcium sulfate hemihydrate whiskers, which includes: in an alkaline environment, subjecting titanium gypsum to water under the action of a composite crystal growth agent. Thermal reaction; wherein, the composite crystal form promoter includes magnesium salt and dodecyl salt.

[0021] The above scheme uses industrial solid waste titanium gypsum as a raw material, which can reduce environmental pollution and ecological damage, and obtains better α-calcium sulfate hemihydrate whiskers with high aspect ratio and high whisker output in an alkaline environment, The reason may be: the composite crystal growth agent containing magnesium salt and dodecyl salt is used. In the reaction process, magnesium salt and dodecyl salt work together, and Mg 2+ Embedded lattice with OH in alkaline environment - The selective adsorption of dodecyl salt is promoted, and then the α-calcium sulfate hem...

Embodiment 1

[0038] The present embodiment provides a preparation method of a high aspect ratio α-calcium sulfate hemihydrate whisker in an alkaline environment, the preparation method comprising the following steps:

[0039] 1) Take material. Weigh 25g of titanium gypsum according to the recipe.

[0040] 2) Prepare the slurry. The weighed titanium gypsum was dissolved in a saturated calcium hydroxide solution, the solid-liquid ratio of the slurry was controlled to be 1:12, and the pH value of the slurry was 12.

[0041] 3) Subsidence. After stirring the prepared slurry, let it stand for 1 min to remove the Al in the bottom layer. 2 O 3 , SiO 2 Wait for the insoluble matter, repeat 3 times, and then transfer the supernatant to the reaction kettle.

[0042] 4) Add crystal form promoter. In the reaction kettle of step 3), add the composite crystal form promoter of magnesium chloride and sodium dodecyl benzene sulfonate, the consumption of magnesium chloride is 6% of the quality of tit...

Embodiment 2

[0047] The present embodiment provides a preparation method of a high aspect ratio α-calcium sulfate hemihydrate whisker in an alkaline environment, the preparation method comprising the following steps:

[0048] 1) Take material. Weigh 25g of titanium gypsum according to the recipe.

[0049] 2) Prepare the slurry. The weighed titanium gypsum was dissolved in a saturated calcium hydroxide solution, the solid-liquid ratio of the slurry was controlled to be 1:12, and the pH value of the slurry was 12.

[0050] 3) Subsidence. After stirring the prepared slurry, let it stand for 1 min to remove the Al in the bottom layer. 2 O 3 , SiO 2 Wait for the insoluble matter, repeat 3 times, and then transfer the supernatant to the reaction kettle.

[0051] 4) Add crystal form promoter. In the reaction kettle of step 3), add the composite crystal form promoter of magnesium sulfate and sodium dodecylbenzenesulfonate, the consumption of magnesium sulfate is 6% of the quality of titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com