Metal bone cement, porous metal microspheres and preparation method of porous metal microspheres

A porous metal and microsphere technology, applied in the field of bone defect repair, can solve problems such as poor mechanical properties, affecting the implantation effect of bone filling materials, poor stability, etc., achieve high precision, realize the integration of function and structure, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] see Figure 4A , Figure 4A It is a schematic diagram of a preparation method according to an embodiment of the present invention. The forming method of porous metal microspheres of the present invention comprises the following steps:

[0042] Step S100, select a degradable metal powder material as required, the metal powder material is magnesium-based metal, zinc-based metal, iron-based metal or molybdenum-based metal, the degradable metal powder is preferably spherical powder, and the powder particle size is in the range of 15 -53μm;

[0043] Step S200, heating and drying the degradable metal powder material in a vacuum drying oven, the heating temperature is 60-150°C, and the drying time is 3-6 hours;

[0044] Step S300 , selecting an alloy with the same composition as the metal powder material as a substrate, and preheating the substrate, and the preheating temperature is 100-200° C.;

[0045] Step S400, designing a three-dimensional model of the porous metal mi...

Embodiment 1

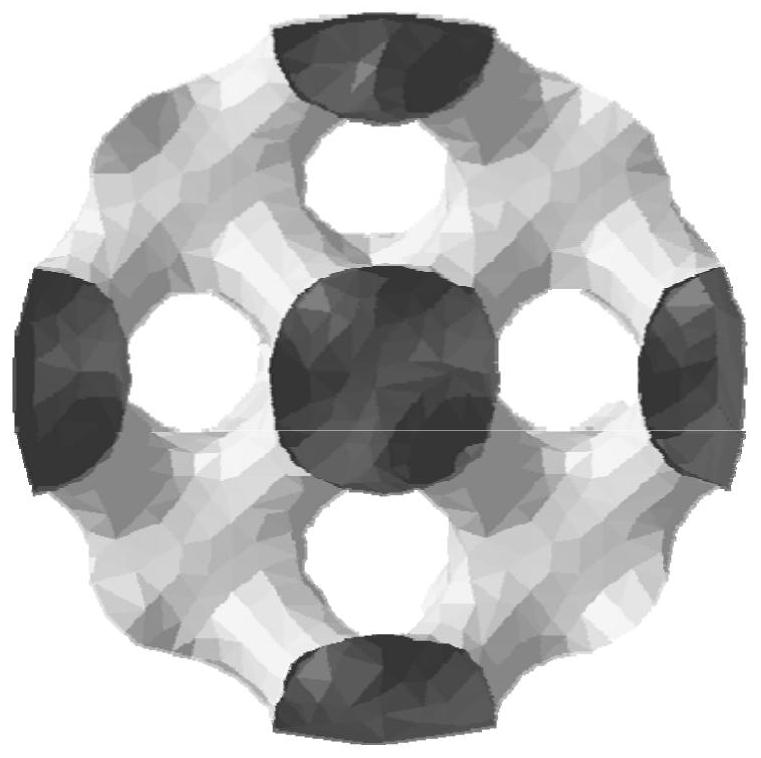

[0053] see Figure 5 , Figure 5 It is the porous pure zinc microsphere of Example 1 of the present invention. In this example, degradable porous pure zinc microspheres with body-centered cubic cell structure were prepared.

[0054] Porous microspheres with an external dimension of 2 mm were designed using Magics software. The interior of the porous microspheres was a body-centered cubic beam-rod cell structure with a rod diameter of 0.3 mm. The porous microsphere model was saved in STL format.

[0055] Select aerosolized spherical pure zinc powder with a particle size distribution of 15-53μm. Put the powder into a vacuum drying oven, the heating temperature is 60°C, and the drying time is 4 hours.

[0056] A pure zinc substrate is selected, and the substrate is preheated at 200°C.

[0057] The porous microsphere STL model was imported into the layering software, supports were added, and sliced at 30 μm per layer.

[0058] Set the laser powder bed fusion printing parame...

Embodiment 2

[0063] see Image 6 , Image 6 It is the porous zinc-magnesium alloy microsphere polyhedron of Example 2 of the present invention. In this example, a degradable porous zinc-magnesium alloy tetrahedron with a diamond cell structure was prepared.

[0064] Magics software was used to design a porous cube with an external dimension of 2 mm. The interior of the porous cube was a diamond beam-rod cell structure with a rod diameter of 0.4 mm. The porous microsphere model was saved in STL format.

[0065] The gas-atomized spherical Zn-3Mg alloy powder is selected, and the particle size distribution of the powder is 15-53 μm. Put the powder into a vacuum drying oven, the heating temperature is 60°C, and the drying time is 4 hours.

[0066] A zinc-magnesium alloy substrate is selected, and the substrate is preheated at 200°C.

[0067] The porous microsphere STL model was imported into the layering software, supports were added, and sliced at 30 μm per layer.

[0068] Set the lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com