Polycarboxylate superplasticizer and preparation method thereof

A technology of water reducer and polycarboxylate, which is applied in the field of polycarboxylate water reducer and its preparation, and can solve the problems of reduced binding rate of polycarboxylate and cement particles, severe cement hydration reaction, and increased concrete slump , to achieve the effect of increased contact amount, increased molecular weight, and improved slump performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] Sa, fully mix 50kg of 4-hydroxybutyl vinyl polyoxyethylene ether, 50kg of ethylene glycol monovinyl polyglycol ether, 1kg of sodium persulfate, 1kg of ammonium persulfate and 4kg of zwitterionic polyacrylamide. Under the atmosphere, the temperature is raised to a reaction temperature of 30 to 45°C to obtain a first mixed solution;

[0053] Sb, add 2kg vinyl silane coupling agent dropwise to the first mixed solution, react at 55~60 ℃ to obtain the second mixed solution;

[0054] Sc, add 40kg 4-aniline sulfonic acid to the second mixed solution, and react at constant temperature for 1~2h to obtain a prepolymer;

[0055] Sd, add 20kg of chain extender to the prepolymer, mix and stir evenly, and react at 75-80 DEG C to obtain a six-carbon polycarboxylic acid mother liquor.

preparation example 2

[0057] Sa, fully mix 50kg of 4-hydroxybutyl vinyl polyoxyethylene ether, 50kg of ethylene glycol monovinyl polyglycol ether, 1kg of sodium persulfate, 1kg of ammonium persulfate and 4kg of zwitterionic polyacrylamide. Under the atmosphere, the temperature is raised to a reaction temperature of 30 to 45°C to obtain a first mixed solution;

[0058] Sb, add 2kg vinyl silane coupling agent dropwise to the first mixed solution, react at 55~60 ℃ to obtain the second mixed solution;

[0059] Sc. Add 20kg of chain extender to the second mixed solution, mix and stir evenly, and react at 75-80° C. to obtain a six-carbon polycarboxylic acid mother solution.

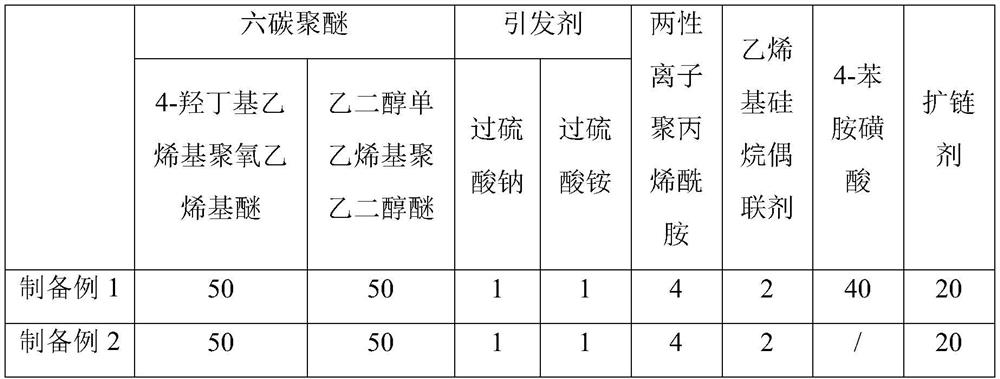

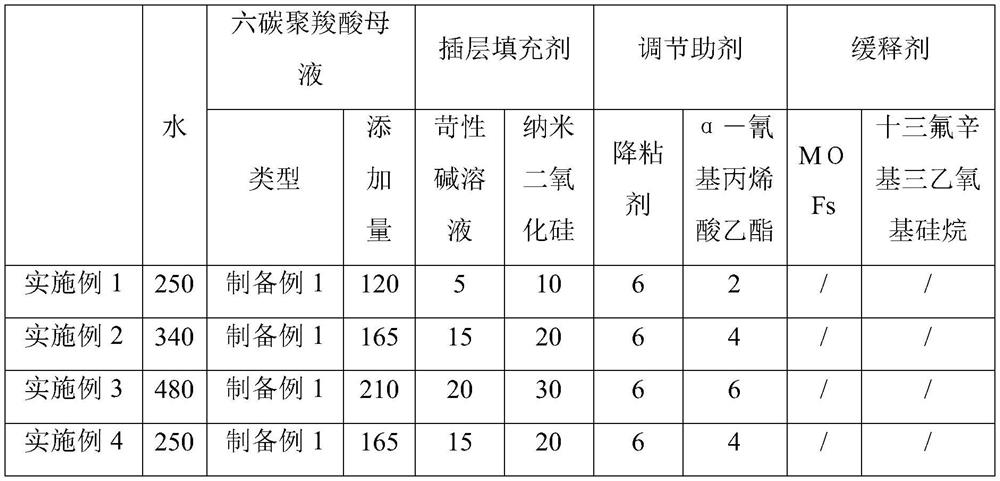

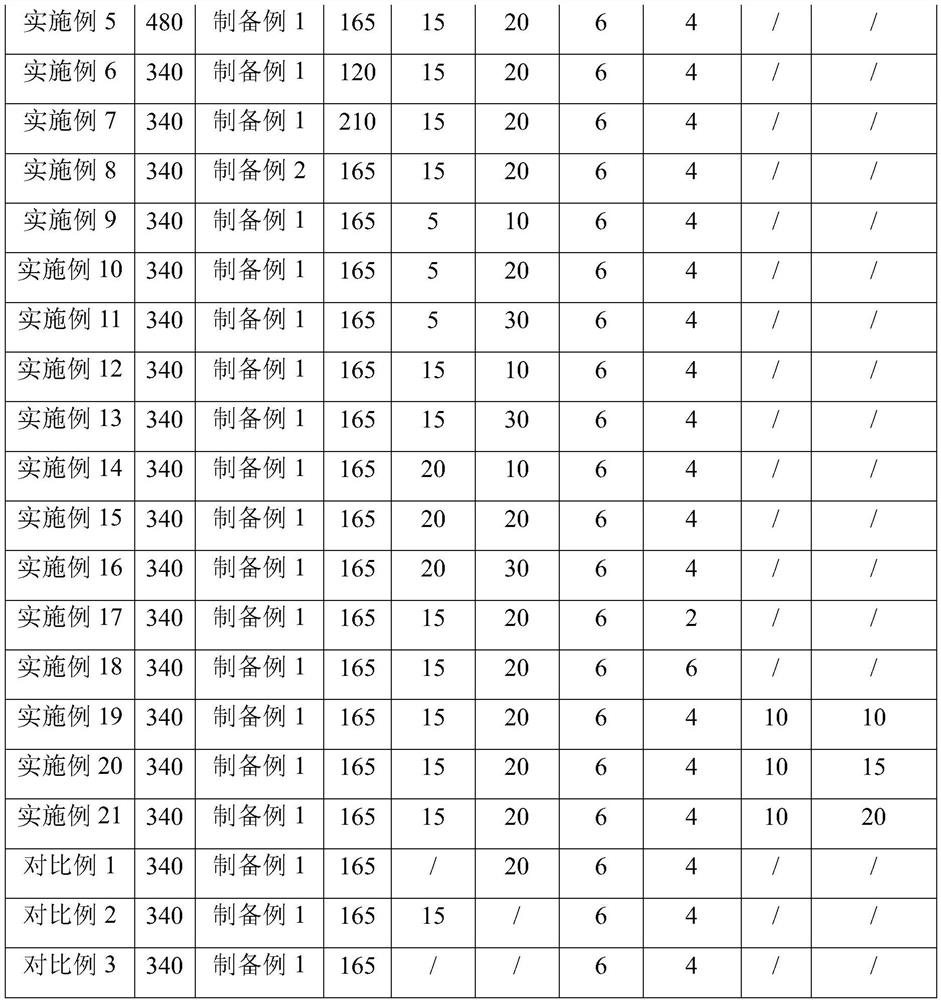

[0060] The raw material table of the preparation example is shown in Table 1:

[0061] Table 1 Raw material table of preparation example (kg)

[0062]

Embodiment 1

[0065] S1, 10kg nano-silicon dioxide is placed in the caustic alkali solution of 5kg, stir and mix, obtain intercalation filler after drying and grinding;

[0066] S2. Add 120kg of the six-carbon polycarboxylic acid mother liquor prepared in Preparation Example 1, 6kg of viscosity reducer, 2kg of α-ethyl cyanoacrylate and intercalation filler to 250kg of water, and mix well to obtain a polycarboxylate water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com