Heat-conducting halogen-free flame-retardant polyolefin cable material for automobile wires and preparation method of heat-conducting halogen-free flame-retardant polyolefin cable material

A technology for polyolefin cable materials and wires, which is applied in plastic/resin/wax insulators, organic insulators, climate change adaptation, etc. It can solve the problems of unsatisfactory aging resistance of cable materials and improve long-term thermal aging resistance and resistance Illumination performance, good fluidity in extrusion processing, and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

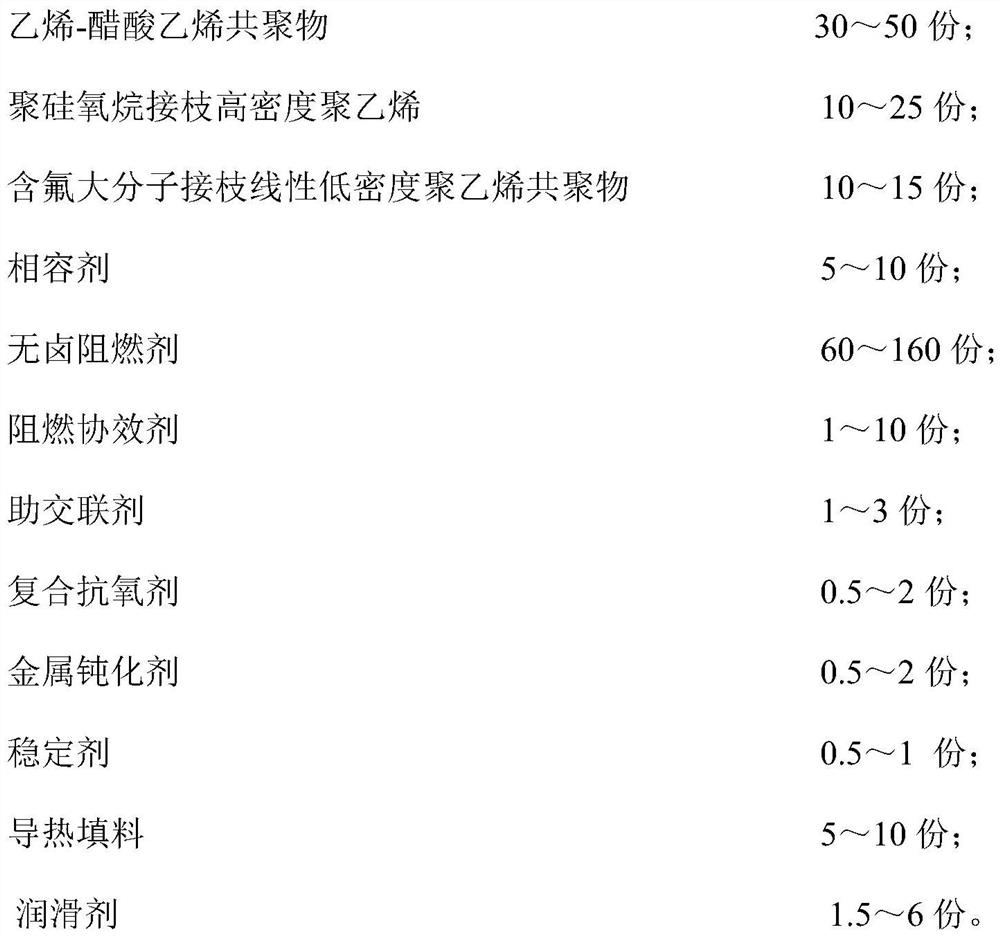

[0030] The present embodiment provides a thermally conductive halogen-free flame retardant polyolefin cable material for automobile wires, which is composed of the following raw materials in proportions by weight:

[0031]

[0032]

[0033] Wherein, the ethylene-vinyl acetate copolymer is an ethylene-vinyl acetate copolymer with a vinyl acetate monomer content of 28% by weight, the trade name is Evatane 28-03, and the melt flow rate is 3.0g / (2.16kg, 10min), The manufacturer is French Atofena; the polysiloxane-grafted high-density polyethylene is polyphenylmethylsiloxane-grafted high-density polyethylene, the grafting rate is 15wt%, and the polysiloxane is polybenzyl Siloxane, molecular weight is 2500g / mol, the supplier is China Hubei Yongkuo Technology Co., Ltd., the melt flow rate of HDPE is 1.0g / (2.16kg, 10min), the grade is 5000S, the manufacturer is China Petrochemical Yangzi Branch; the fluorine-containing macromolecular graft linear low-density polyethylene copolymer...

Embodiment 2

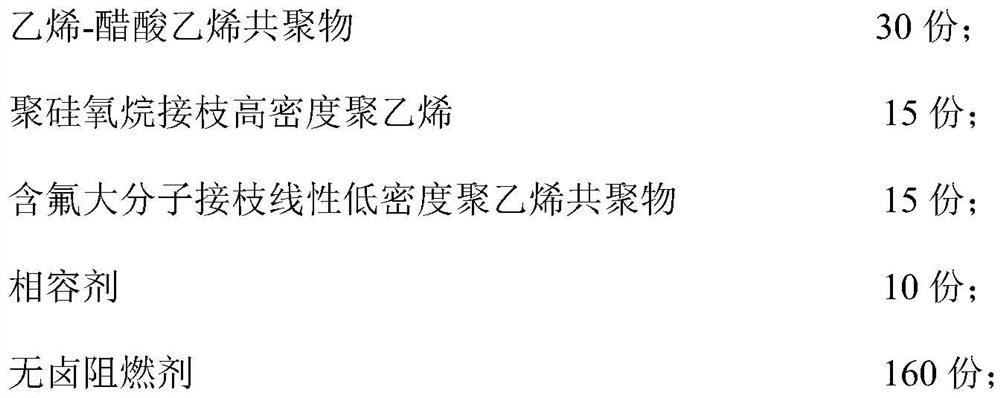

[0040] The present embodiment provides a thermally conductive halogen-free flame retardant polyolefin cable material for automobile wires, which is composed of the following raw materials in proportions by weight:

[0041]

[0042] Wherein, the ethylene-vinyl acetate copolymer is an ethylene-vinyl acetate copolymer with a vinyl acetate monomer content of 28% by weight, the trade name is Evatane 28-03, and the melt flow rate is 4.0g / (2.16kg, 10min), The manufacturer is French Atofina; the polysiloxane-grafted high-density polyethylene is polyphenylmethylsiloxane-grafted high-density polyethylene, the grafting rate is 20wt%, and the polysiloxane is polybenzyl Siloxane, molecular weight is 2600g / mol, the supplier is China Hubei Yongkuo Technology Co., Ltd., the melt flow rate of HDPE is 3.0g / (2.16kg, 10min), the grade is 5000S, the manufacturer is China Petrochemical Yangzi Branch; the fluorine-containing macromolecular graft linear low-density polyethylene copolymer is a fluo...

Embodiment 3

[0049] The present embodiment provides a thermally conductive halogen-free flame retardant polyolefin cable material for automobile wires, which is composed of the following raw materials in proportions by weight:

[0050]

[0051] Wherein, the ethylene-vinyl acetate copolymer is an ethylene-vinyl acetate copolymer with a vinyl acetate monomer content of 28% by weight, the trade name is Evatane 28-03, and the melt flow rate is 1.0g / (2.16kg, 10min), The manufacturer is French Atofena; the polysiloxane-grafted high-density polyethylene is polyphenylmethylsiloxane-grafted high-density polyethylene, the grafting rate is 30wt%, and the polysiloxane is polybenzyl Siloxane, molecular weight is 2700g / mol, the supplier is China Hubei Yongkuo Technology Co., Ltd., the melt flow rate of HDPE is 2.0g / (2.16kg, 10min), the grade is 5000S, the manufacturer is China Petrochemical Yangzi Branch; the fluorine-containing macromolecular graft linear low-density polyethylene copolymer is a fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com