Device and method for cleaning semiconductor wafer after wet etching of oxide layer

A wet etching and semiconductor technology, applied in the field of microelectronics, can solve problems such as low flow speed, reduced operating efficiency, particle pollution, etc., and achieve the effect of enhancing the scouring ability and increasing the scouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

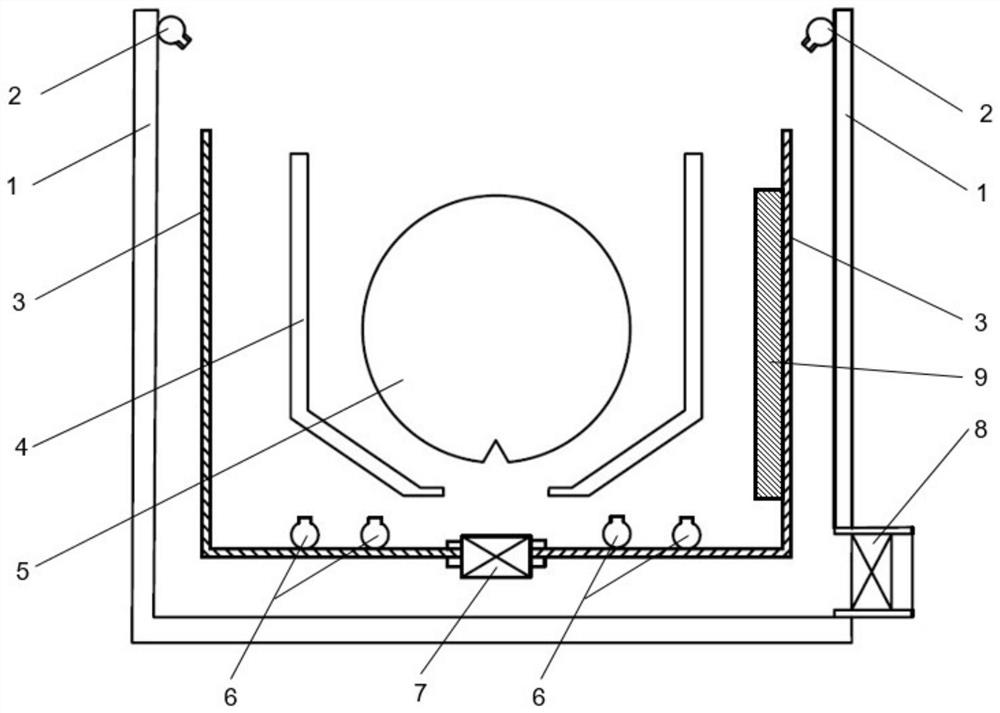

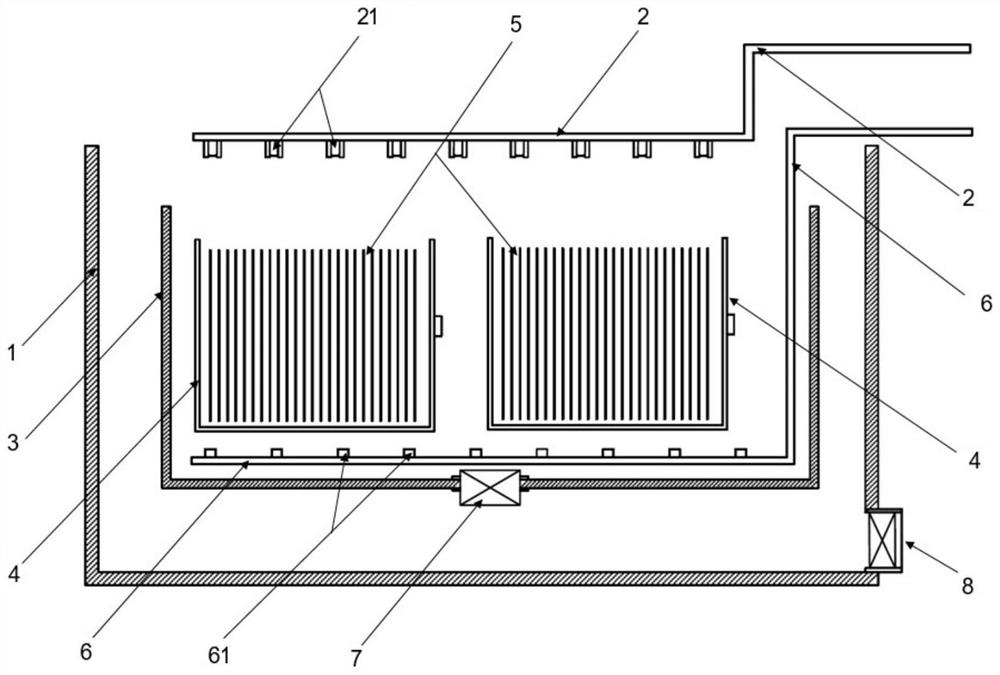

[0037] like figure 1 and figure 2 It is shown that the embodiment is used to clean the device of the semiconductor wafer of the rear semiconductor wafer of the wetting method of the wetting method, including outer slot 1, the inner slot 3 inside the outer slot 1, and the inner slot 3 is used to place it to clean the semiconductor crystal crystal The round Jingzhou 4, the top cloth of Jingzhou 4 is equipped with two spray water pipes 2 for spraying to clean the semiconductor wafer, and the spray water pipe 2 is installed on the left and right sides of the long side of the outer groove 1, which is higher than the height than Inner groove 3 overall height; the bottom of the inner slot 3 is provided with several water supply pipes 6 and the first fast drainage valve 7. In the present invention, the number of spray water pipe 2 and its diameter can be adjusted regularly according to actual needs.

[0038] In the present invention, the inner slot is set in the outer groove, and the spra...

Embodiment 2

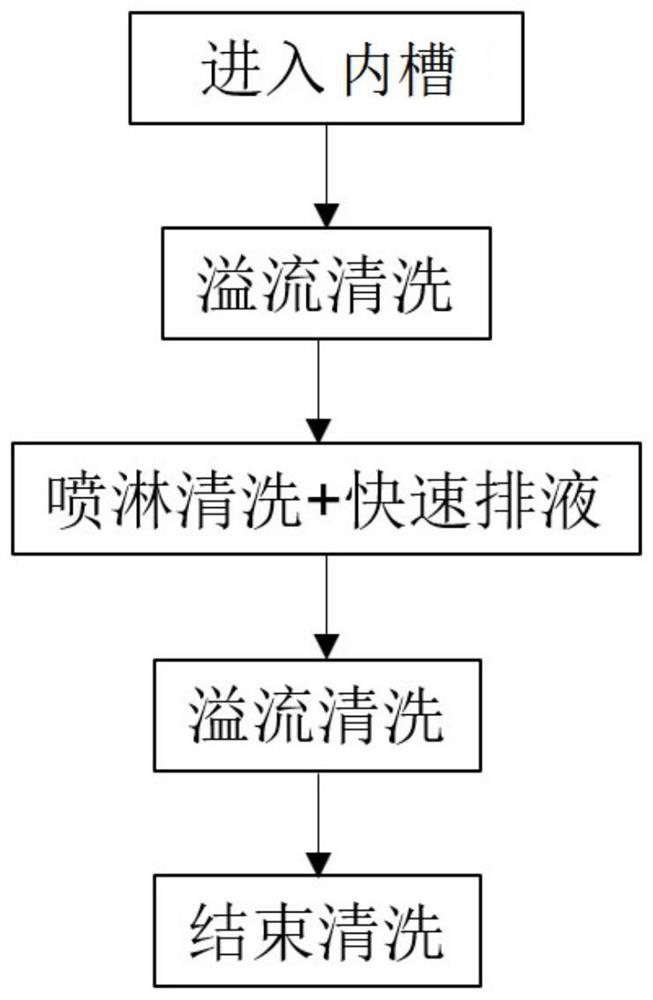

[0045] A method for cleaning the wet etching oxide layer's rear semiconductor wafer, specifically the device used in an embodiment 1 for cleaning the wet etching oxidation layer's rear semiconductor wafer Cleaning treatment of the rear semiconductor wafer) of the oxygen layer, the schematic diagram of the cleaning process is image 3 It includes the following steps:

[0046] S1. Place semiconductor wafer 5 after the completion of the wet etching oxide layer is placed in Jingzhou 4, put it into the inner slot 3, open the first fast drain valve 7, and open the spray water pipe 2 at the same time. Under the condition of 40L / min, the washing semiconductor wafer was scrubbed at 150s. In this step, in the traditional cleaning scheme, due to the adsorption of chemicals, and the pellets due to the pressure of the wafer surface, the particles are only under the pressure of the water pressure and have no internal cutting effect. The cleaning effect of the particles is not ideal. Based on thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com