Silicon-based gallium nitride epitaxial wafer and manufacturing method thereof

A manufacturing method and epitaxial wafer technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of high dislocation density in GaN epitaxy, and achieve good stress transfer and coordinated release effects , reduce thermal mismatch, reduce the effect of lattice mismatch and thermal mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

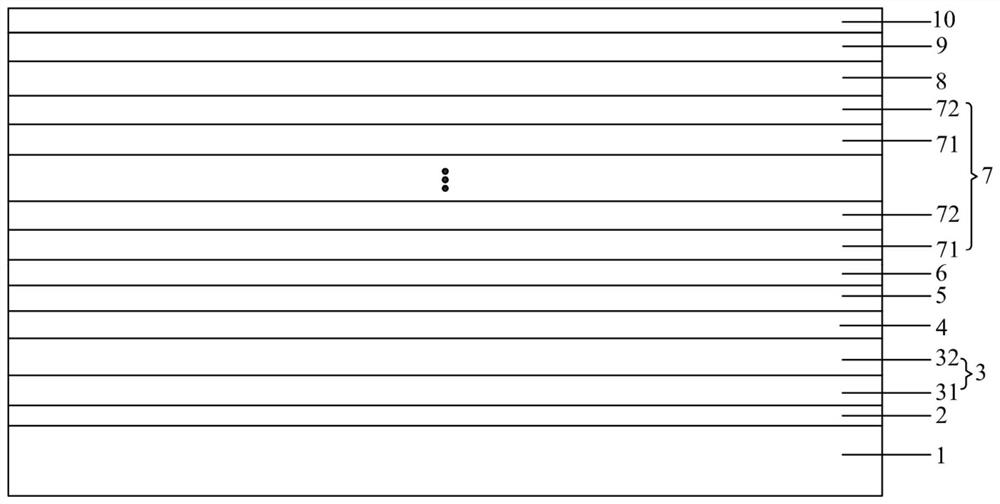

[0048] See figure 1 It is a structural diagram of a silicon -based nitrogen nitrogen -nitride extension of the embodiments of the present invention. In order to facilitate the explanation, only parts related to the embodiments of the invention are displayed. The film includes:

[0049] Silicon lining 1. AL layer on the silicon substrate 1 in sequence 2. ALN formation of nuclear layer 3. Stress variable layer 4. N. N, bits and fine -tuning layers 6, multi -quantum trap layer 7, electronic blocking layer, electronic blocking layer 8. P -shaped layer 9 and P type contact layer 10;

[0050] Aln formation nuclear layer 3 includes Aln three -dimensional nuclear layer 31 and ALN two -dimensional nuclear layer 32;

[0051] Stress Merrage 4 is Al x B y GA 1-x-y N layer, of which 0

[0052] The fine -tuning layer 6 is any or more combination of Aln layer, BN layer, and Bgan layer.

[0053] Among them, in one embodiment of the present invention, it uses silicon substrate ...

Embodiment 2

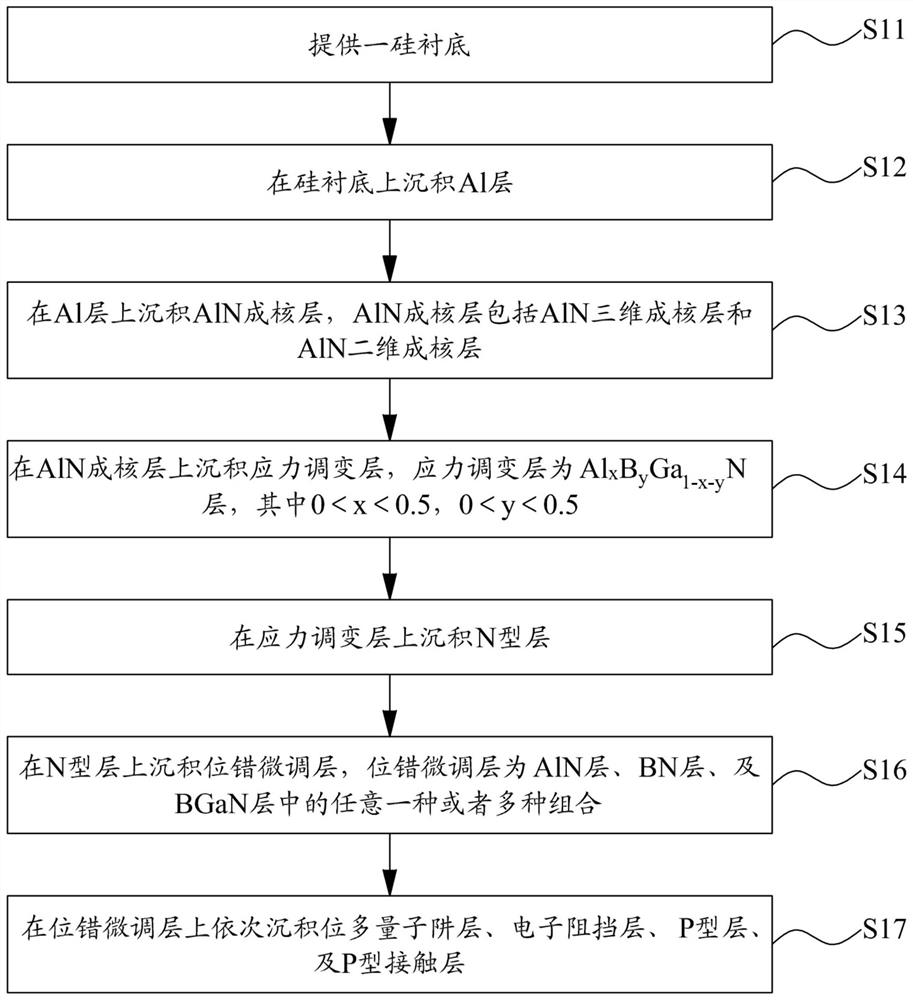

[0068] See figure 2 It is a silicon -based nitrogen -nitride extension chip preparation method in the second embodiment of the present invention, which specifically includes step S11 to step S17.

[0069] Step s1, provide a silicon substrate.

[0070] Among them, in the embodiments of the present invention, the specific use of silicon substrate is used as the extension of the substrate, and it can be graphical silicon substrate or flat silicon lining when used. Further, the present invention uses metal organic chemical gas deposition (MOCVD) equipment to grow extension. Among them, high -purity ammonia (NH 3 ) As a source of N (nitrogen), the three -based base (TMGA) as the source of GA (镓), the three -based 铟 (TMIN) is in (铟) source, and the triangular aluminum (TMAL) is used as Al (aluminum) source, Boron chloride (BCL 3 ) As a source of B (boron), the Sih (SIH 4 ) As a N -type dopant, Er Mao Magnesium (CP 2 Mg) as a P -type dopant. By adopting high -pure H 2 (Hydrogen) or n 2 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com