Organic/inorganic composite three-dimensional porous nanofiber tissue engineering scaffold as well as preparation method and application thereof

A tissue engineering scaffold and organic nanofiber technology, applied in the medical field, can solve problems such as poor mechanical strength, improve mechanical properties, facilitate ingrowth and proliferation, and promote blood vessel regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] SiO 2 Preparation of Nanofibrous Membranes:

[0030]Ethyl orthosilicate, deionized water, and phosphoric acid are mixed in a molar ratio of 1:11:0.01, and stirred for 30 hours to obtain a silica sol solution; PVA and deionized water are mixed in a mass ratio of 1:9, and then heated and stirred until PVA is completely dissolved to form a uniform PVA aqueous solution with a mass fraction of 10%;

[0031] The first electrospinning solution was obtained by mixing the above-mentioned silica sol solution with the above-mentioned PVA aqueous solution, adding it into a syringe, installing it on a propelling pump, connecting the high voltage and setting the electrospinning high voltage to be 20kV, and the propelling speed to be 1mL / h, Aluminum foil was used as the receiving device, and the receiving distance was 20 cm, and SiO was obtained by electrospinning. 2 / PVA nanofiber membrane;

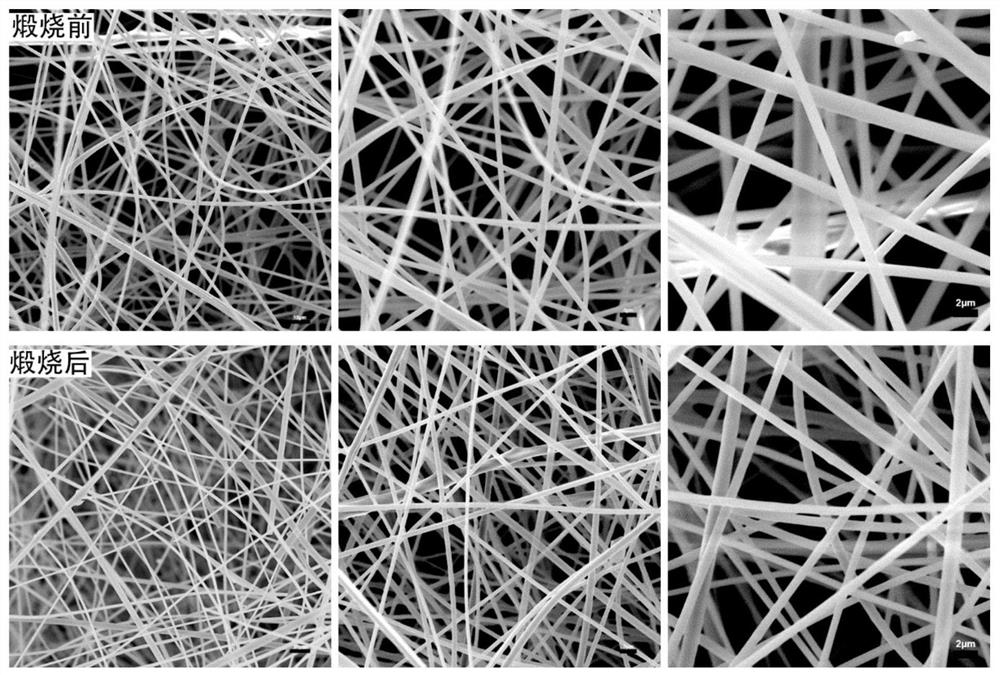

[0032] the SiO 2 / PVA nanofiber membrane was calcined at 800 °C for 2 h to obtain pure S...

Embodiment 2

[0035] Preparation of PLLA / Gelatin nanofiber membranes:

[0036] Gelatin and PLLA were mixed and dissolved in hexafluoroisopropanol at a mass ratio of 5:1 (the total mass of gelatin and PLLA dissolved in hexafluoroisopropanol per milliliter was 0.1 g) to form a second electrospinning method. Silk liquid, add it to the syringe, install it on the propelling pump, connect the high voltage, set the high voltage for electrospinning to 15kV, the propelling speed to 3mL / h, the aluminum foil as the receiving device, the receiving distance to be 10cm, and electrospinning to obtain PLLA / Gelatin nanofiber membrane.

Embodiment 3

[0038] Preparation of organic / inorganic composite three-dimensional porous nanofibrous tissue engineering scaffolds:

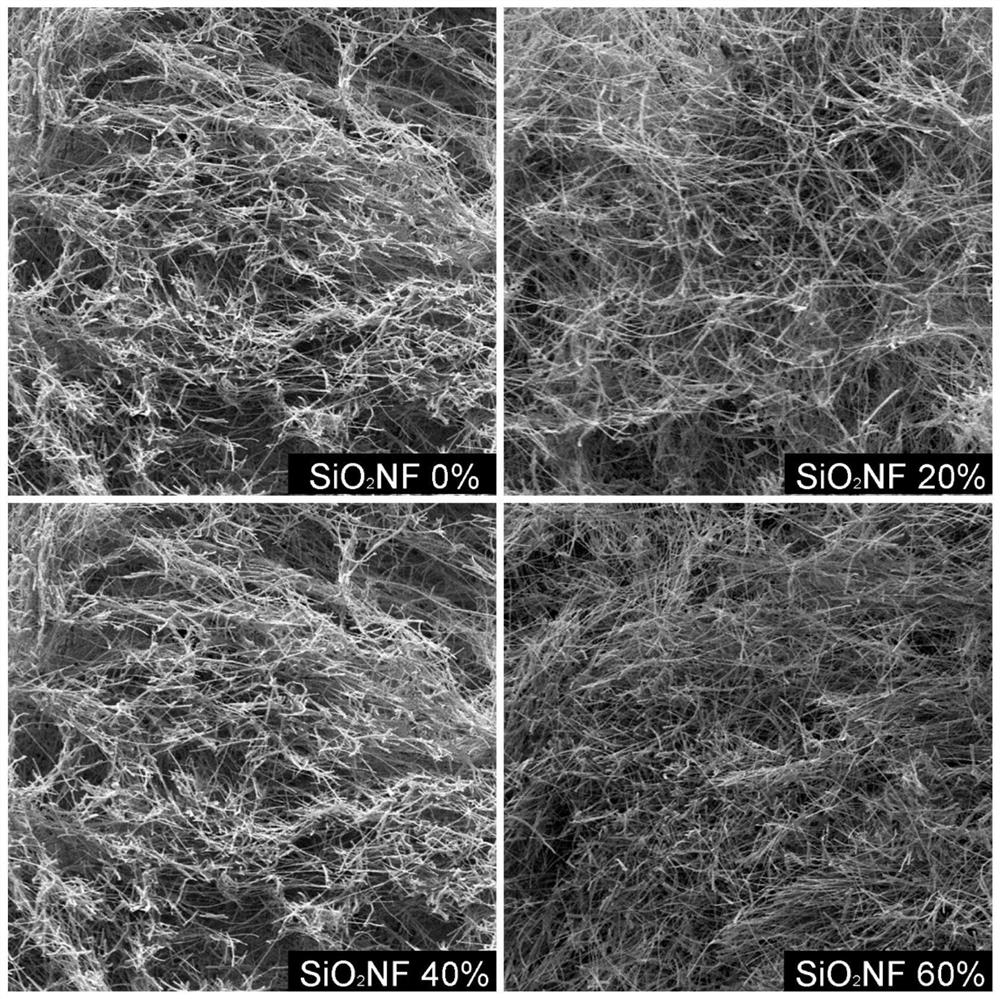

[0039] Take the SiO in Example 1 2 A total of 2.5 g of the nanofiber membrane and the PLLA / Gelatin nanofiber membrane in Example 2 formed mixed nanofibers, in which SiO 2 The proportion of the nanofiber membrane to the total mass of the mixed nanofibers is 0%, 20%, 40%, 60%, and the mixture is cut into pieces of 1cm×1cm size;

[0040] Add 2.5g of mixed nanofibers to 100mL of tert-butanol, and use a high-speed homogenizer to homogenize and smash into a uniform mixed nanofiber solution;

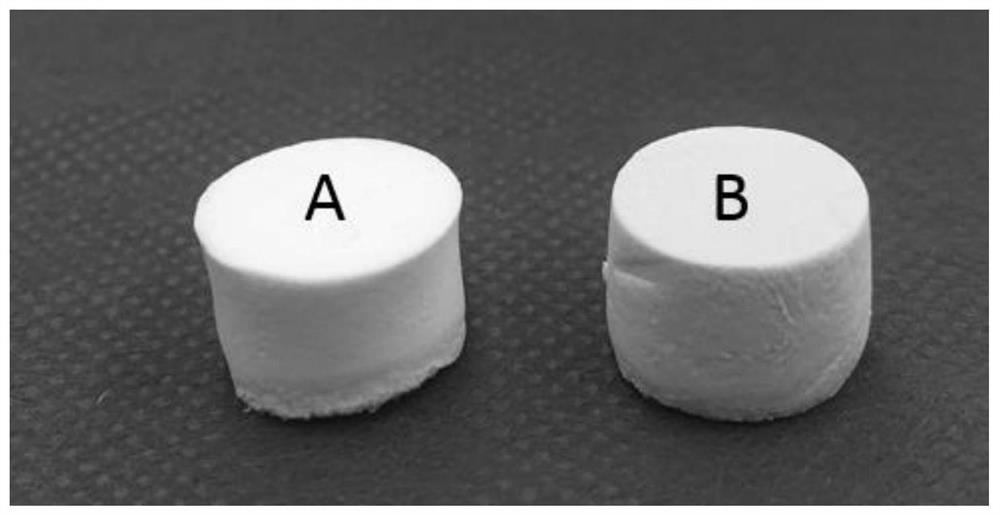

[0041] Pour the mixed short nanofiber solution into the mold, freeze it in a -80°C refrigerator for 24 hours, then take it out and place it in a freeze dryer for 3 days of freeze drying to obtain an uncrosslinked organic / inorganic composite nanofiber tissue;

[0042] The cross-linked organic / inorganic composite nanofibrous tissue was placed in a muffle furnace and heated to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com