Catalyst for deeply removing olefin in aromatic hydrocarbon and preparation method thereof

An olefin catalyst and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, hydrogenation and refining of aromatics, etc., can solve the problems of disrupting the continuity of industrial production, short life of clay catalysts, and non-renewable, so as to reduce solid waste The effect of generation, life extension, and loss of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

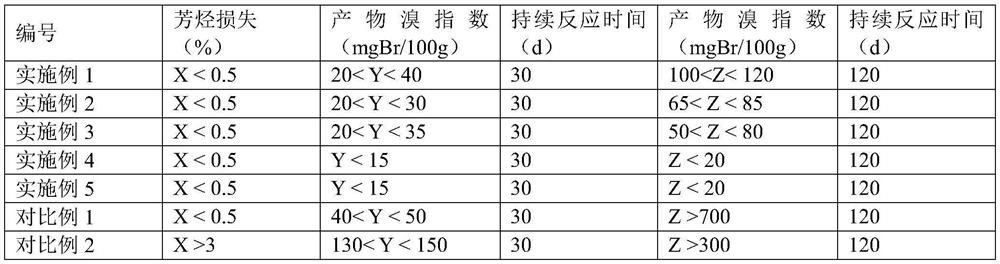

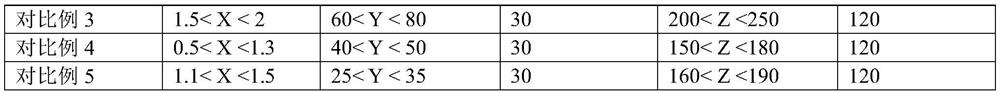

Examples

preparation example Construction

[0033] 1. Preparation of catalysts for deep removal of olefins in aromatics

[0034] The catalyst includes 50-150% by mass of molecular sieve, 5-40% by mass of binder, 0-20% by mass of metal and / or metal oxide, and 0-10% by mass of auxiliary agent.

[0035] Wherein, the metal is one or more of hydrogenation metal and alkaline earth metal, the hydrogenation metal is platinum, palladium, rhodium, nickel, cobalt, iron, copper or molybdenum, and the alkaline earth metal is beryllium, magnesium, calcium, strontium or barium .

[0036] Molecular sieve is one or more of Y molecular sieve, MWW series molecular sieve, X molecular sieve, USY molecular sieve, SBA-15 molecular sieve, ZSM-5 molecular sieve, β molecular sieve, AIPO-5 phosphorus-aluminum molecular sieve, MWW series molecular sieve is MCM-36, MCM-49 or MCM-56 molecular sieve.

[0037] The binder is one or more of silica sol, alumina, natural clay, water glass, methyl cellulose, paraffin, starch, plastic resin, bentonite, an...

Embodiment 1

[0049] The catalyst for deep removal of olefins in aromatic hydrocarbons includes 55% mass fraction of Y molecular sieve, 15% mass fraction of MCM-36 molecular sieve, 26% mass fraction of alumina, 8% mass fraction of beryllium oxide and 1% mass fraction of molybdenum oxide, 4% mass fraction of turmeric powder.

[0050] The preparation method of above-mentioned deep removal of olefin catalyst in aromatics comprises the steps:

[0051] (1) fully mix the Y molecular sieve, MCM-36 molecular sieve, alumina and succulent powder respectively after pulverizing;

[0052] (2) mixing after adding the nitric acid solution to the above-mentioned mixture, the liquid-solid mass ratio after adding the solvent is 0.5:1, and then extrusion molding obtains a clover-shaped molding catalyst;

[0053] (3) The shaped catalyst was impregnated with 8% mass fraction of beryllium oxide and 1% mass fraction of molybdenum oxide by the equal volume method, then dried, and calcined at 500° C. for 3 hours t...

Embodiment 2

[0056] The catalyst for deep removal of olefins in aromatic hydrocarbons includes 70% mass fraction of ZSM-5 molecular sieve, 26% mass fraction of alumina, 0.2% mass fraction of platinum, 1% mass fraction of molybdenum oxide, 5% mass fraction of barium oxide, 4 % mass fraction of turmeric powder.

[0057] The preparation method of above-mentioned deep removal of olefin catalyst in aromatics comprises the steps:

[0058] (1) fully mix ZSM-5 molecular sieve, alumina and succulent powder respectively after pulverizing;

[0059] (2) mixing after adding the nitric acid solution to the above-mentioned mixture, the liquid-solid mass ratio after adding the solvent is 0.5:1, and then extrusion molding obtains a clover-shaped molding catalyst;

[0060] (3) The shaped catalyst was impregnated with 0.2% mass fraction of platinum, 1% mass fraction of molybdenum oxide and 5% mass fraction of barium oxide by the equal volume method, then dried and calcined at 400° C. for 4 hours to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com