Nitrogen doped titanium oxide mesoporous photocatalysis material and preparation method thereof

A photocatalytic material, titanium oxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of titanium oxide lattice deformation, the difficulty of controlling the ratio of anatase and rutile mixed crystals, etc. problems, to achieve the effect of improving utilization efficiency, good industrial production prospects, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

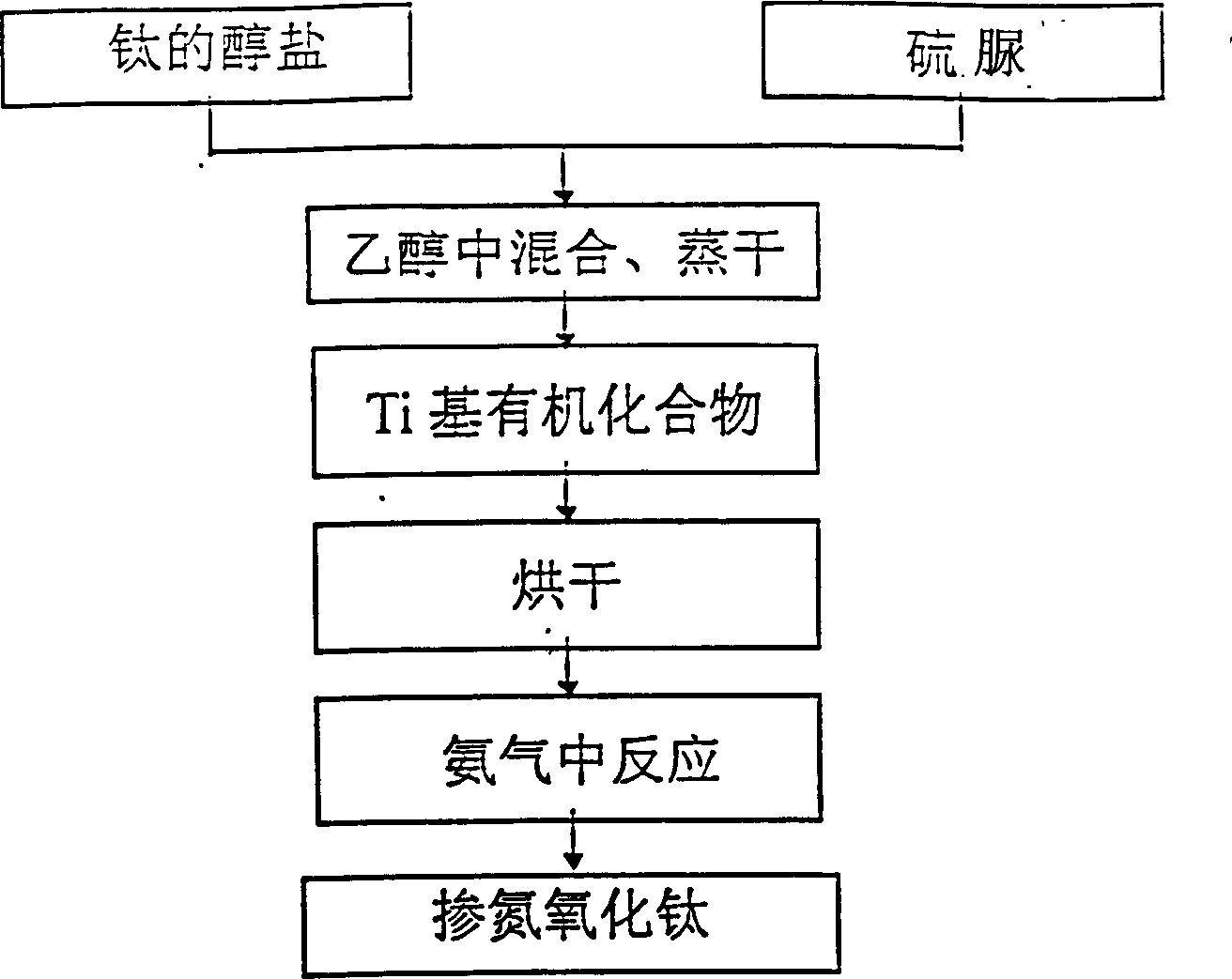

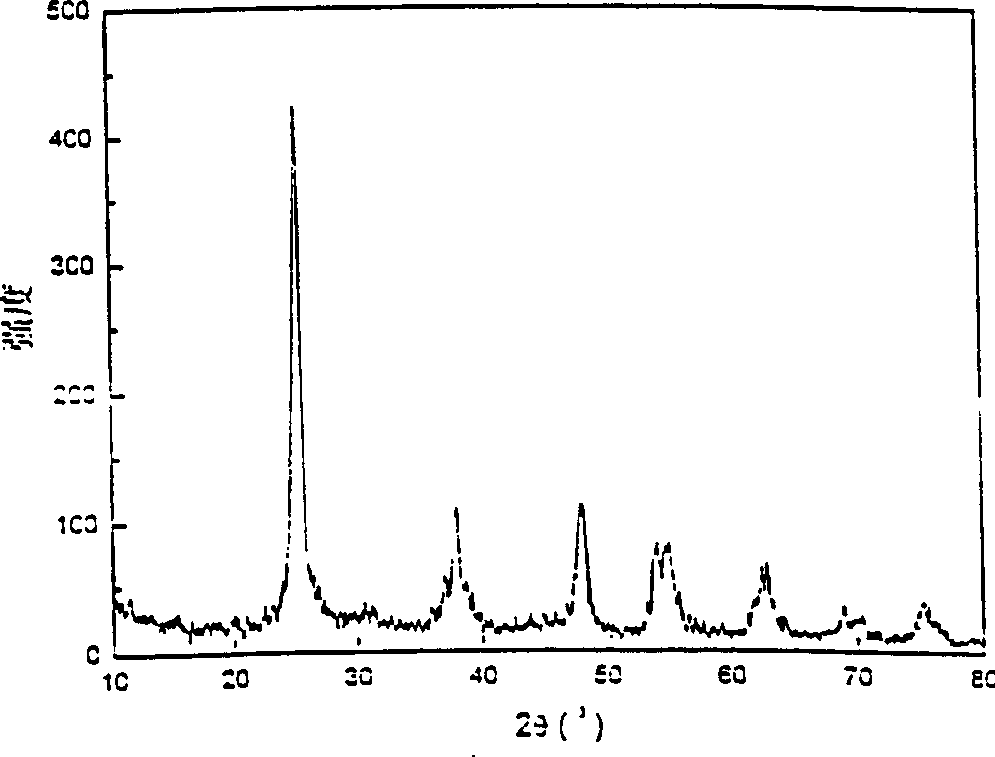

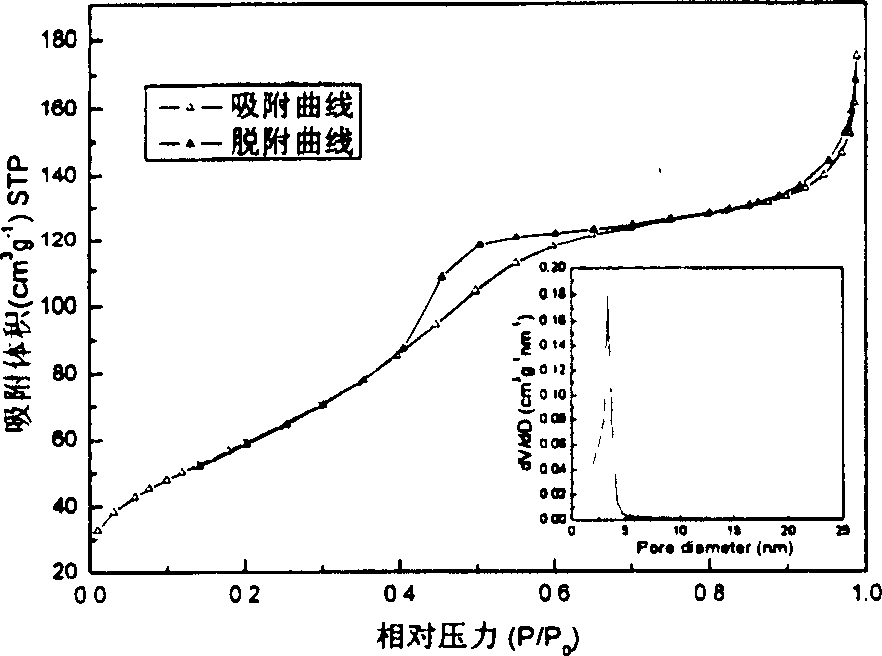

[0035] 34.0g butyl titanate and 30.4g thiourea were mixed and stirred in ethanol solvent for 2 hours, then evaporated to remove ethanol, dried at 80~C to obtain white precursor powder, and then treated in ammonia flow at 450~C for 6 hours, The obtained reddish-brown substance is N-doped titanium oxide powder after grinding. The particle size of the powder is 10-40nm. A 300W high-pressure mercury lamp with a cut-off wavelength of 400nm was used as a light source, and 0.3g of photocatalyst was suspended in 400ml of 50mg / L methylene blue aqueous solution to test its photocatalytic performance. figure 2 Its XRD pattern shows titanium oxide in the anatase phase. image 3 It is the nitrogen adsorption / desorption curve and the corresponding pore size distribution diagram, showing an average pore size of 4.2nm and a specific surface area of 217m2 / g. Elemental analysis indicated that the sample contained 2.2% nitrogen. Figure 4 For the UV-vis absorption spectrum plant, the (c) c...

Embodiment 2

[0037] Nitrogen-doped anatase titanium oxide powder was obtained by treating the precursor at 500°C for 3 hours in an ammonia flow. Other experimental steps are the same as in Example 1. Elemental analysis indicated that the sample contained 7.6% nitrogen. The prepared photocatalyst can degrade 89% of methylene blue after 4 hours of visible light irradiation.

Embodiment 3

[0039] Nitrogen-doped anatase titanium oxide powder was obtained by treating the precursor at 550°C for 3 hours in an ammonia flow. Other experimental steps are the same as in Example 1. Elemental analysis indicated that the sample contained 1.6% nitrogen. The prepared photocatalyst can degrade 85% of methylene blue after 4 hours of visible light irradiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com