Liquid nanometer simple substance silver antibacterial agent and preparation method thereof

A nano-element, antibacterial agent technology, applied in the field of antibacterial agents, can solve the problems of prolonged production cycle, application limitation, large product particle size, etc., and achieves the effects of high content of active ingredients, reduced production cost, and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the preparation process of nano-silver, the requirements for water are very strict. Generally adopt distilled water, pure water in the prior art, although tap water is cheap and good-looking, but seldom adopts, this is because tap water contains more Cl - , will react with silver ions to form white AgCl precipitates, on the one hand, it will reduce Ag + At the same time, the AgCl particles generated are equivalent to adding a nucleating agent to make the generated nano-silver particles larger. Therefore, in the prior art, in the process of preparing nano-silver, distilled water or pure water must be used to exclude Cl - interference. After repeated studies, the applicant has tested again, although the silver nitrate or silver sulfate solution prepared by tap water is due to some Ag + It turns into AgCl and becomes white and turbid, but after mixing with silver complexing agent and stirring for a period of time, the white precipitate will disappear and become a col...

Embodiment 1

[0040] (1) 0.5% betaine type polymer and 47% tap water are mixed to be betaine type polymer aqueous solution; Then 0.5% hydrogen peroxide and 50% tap water are mixed into hydrogen peroxide solution;

[0041] (2) Add the betaine type polymer aqueous solution in the reaction kettle, add 2% silver nitrate at the stirring speed of 800r / min in the high-speed disperser, and stir for about 1.5 hours to make the silver ion and the betaine type polymer The solution fully undergoes a complexation reaction;

[0042] (3) Finally, the aqueous hydrogen peroxide solution is sprayed in the solution obtained in step (2) through the sprayer and under the flow control of 1000ml per minute. After the spraying ends, continue to stir the reaction and stir for 1 hour, and then The liquid nanometer elemental silver antibacterial agent is obtained.

Embodiment 2

[0044] (1) 5% polymaleic acid is mixed with 44% distilled water to be polypolymaleic acid aqueous solution; Then 3% sodium borohydride and 45% distilled water are mixed into sodium borohydride aqueous solution;

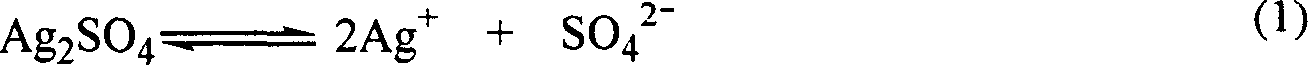

[0045] (2) Add the polymaleic acid aqueous solution in the reaction kettle, add 3% silver sulfate under the stirring speed of 700r / min in the high-speed disperser, stir for 1 hour to make the silver ion and the polymaleic acid solution fully intertwine Combined reaction;

[0046] (3) Finally, the aqueous solution of sodium borohydride is sprayed into the solution obtained in step (2) through the sprayer and under the flow control of 800ml per minute. After the spraying ends, continue to stir the reaction and stir for 1 hour, and then The liquid nanometer elemental silver antibacterial agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com