Method and device for atmospheric plasma processing

A technology of atmospheric pressure plasma and treatment method, which is applied in the field of atmospheric pressure plasma treatment and its device, and can solve the problems of unfavorable industrial adoption, incapable of surface modification treatment, inability to obtain high-quality semiconductor components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Using the apparatus shown in FIG. 11, using nitrogen as a specific gas, plasma was generated under the following conditions while exhausting, and a 2-inch (100) silicon wafer was dry-etched. Where the solid dielectric is Al 2 O 3 , The plasma emission aperture is set to 1 mm, and the distance from the plasma blowing port to the base material is set to 2 mm.

[0116] Plasma treatment conditions:

[0117] Processing gas: oxygen 0.1SLM+CF 4 0.4SLM+argon 9.5SLM mixed gas

[0118] Discharge conditions: waveform a, rise / fall time 5 microseconds, output 200 watts, frequency 10kHz, treatment time 20 seconds, the plasma generated is uniform discharge without arc.

[0119] The surface of the obtained silicon wafer was measured by a scanning electron microscope cross-sectional observation method, and the etching depth was 0.2 microns.

Embodiment 2

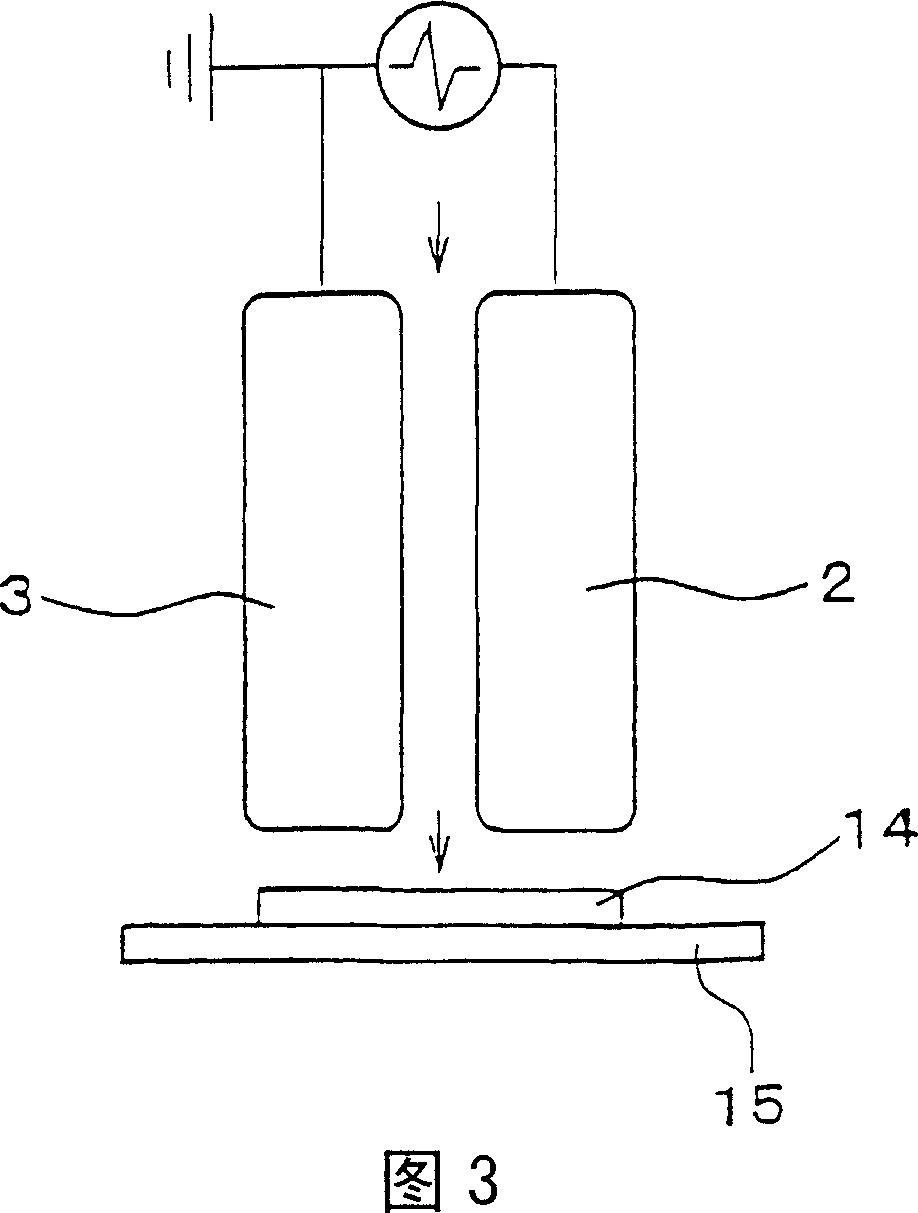

[0125] 4 Parallel plate electrodes made of stainless steel are used as the upper electrode 2 and the lower electrode 3, and aluminum with a thickness of 1 mm is used as the solid dielectric 4. In the space with a distance of 2 mm between the electrodes, a polyimide film 14 (size: The device shown in Figure 14 is used to contact the plasma with the object to be processed in a container filled with a specific gas, and nitrogen is formed on the base material. Silicon film. In the device shown in Figure 14, SUS30100×100mm, thickness 50 microns (300 mm wide×100 mm long×20 mm thick) is used as the film-forming base material, and conveyed by conveying rollers and winding rollers.

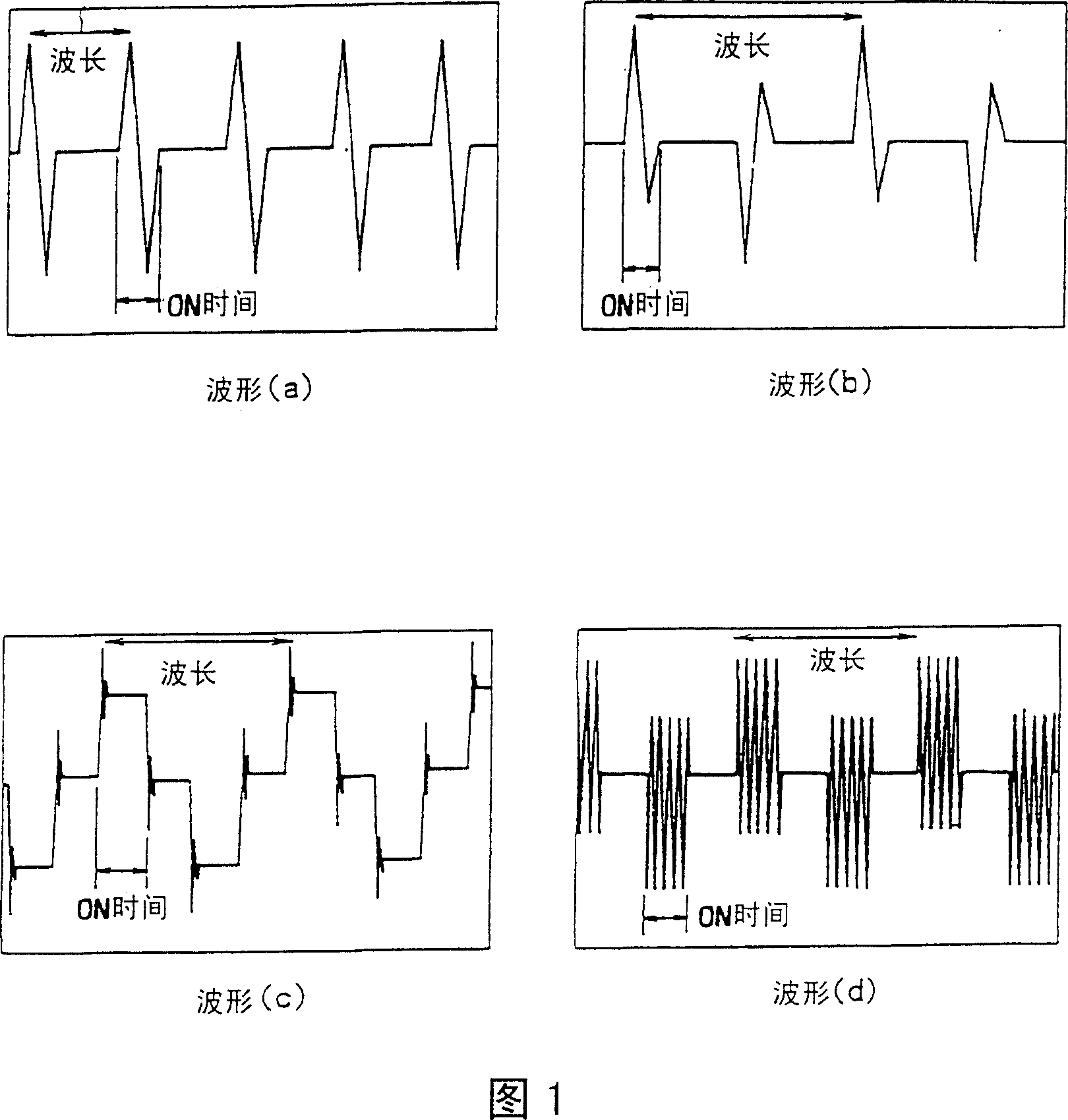

[0126] Using 0.16% tetramethylsilyl and 16% ammonia diluted with argon as the processing gas, it is supplied along the white empty arrow, and the waveform of Figure 1(a) is applied between the upper electrode 2 and the lower electrode 3. A pulse waveform, a rise time of 5 microseconds, and a pulsed electric fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com