Laser modulation driving circuit having self-regulating constant current source

A driving circuit, constant current source technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as deviation from ideal design values, output voltage amplitude changes, and yield decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

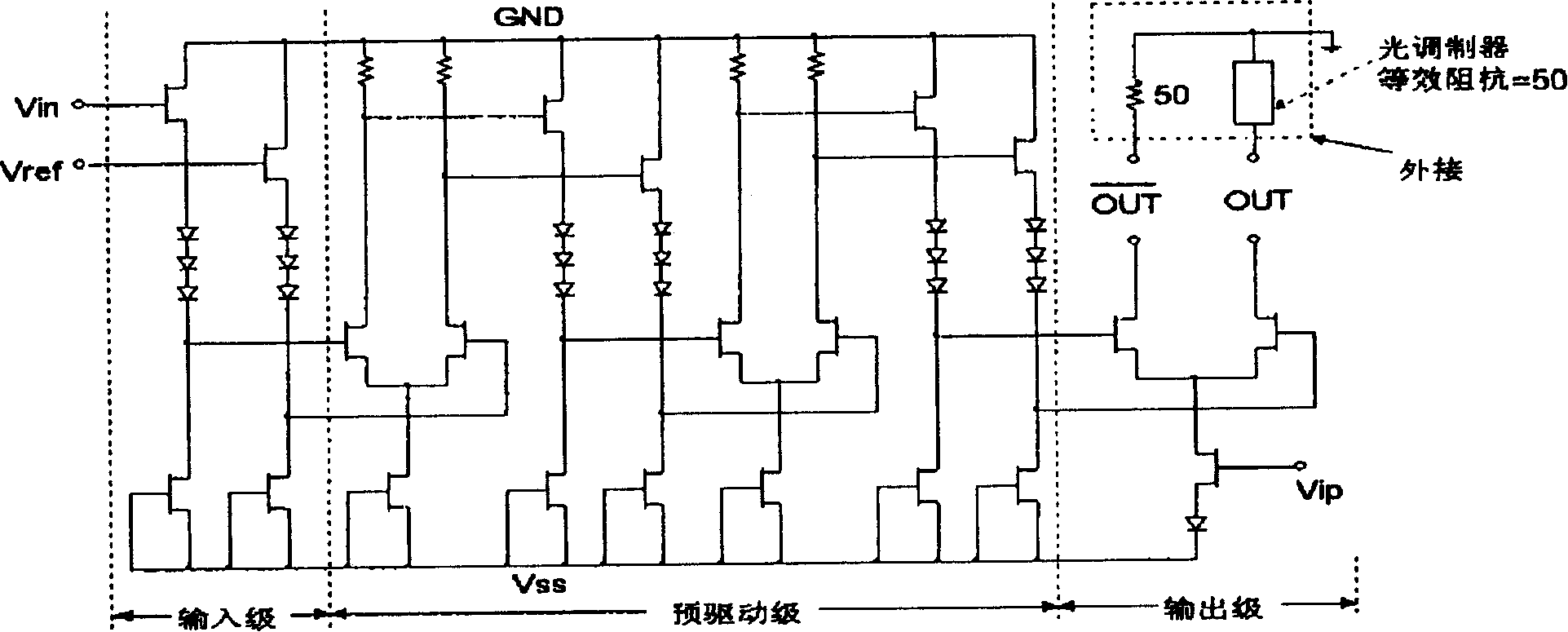

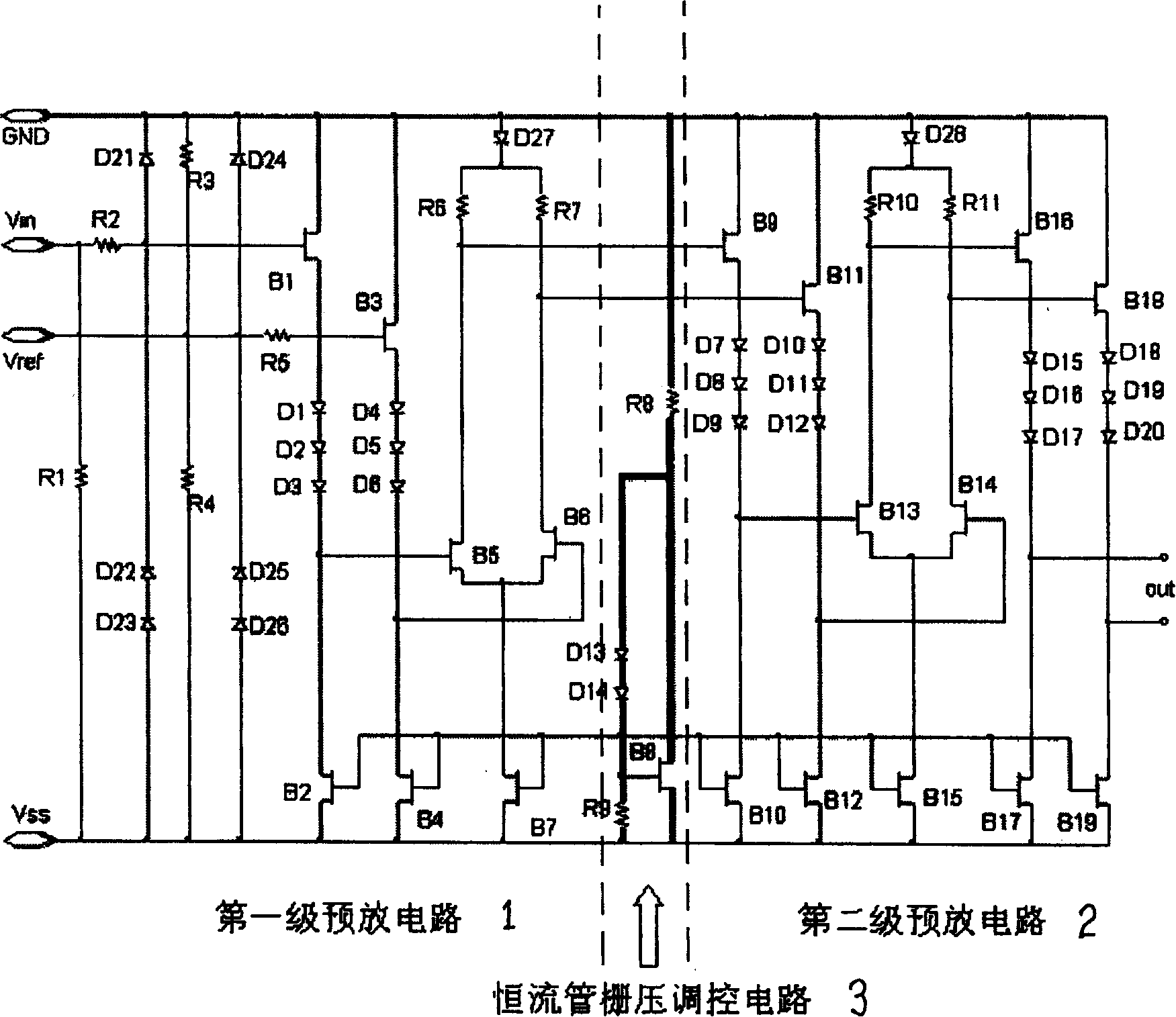

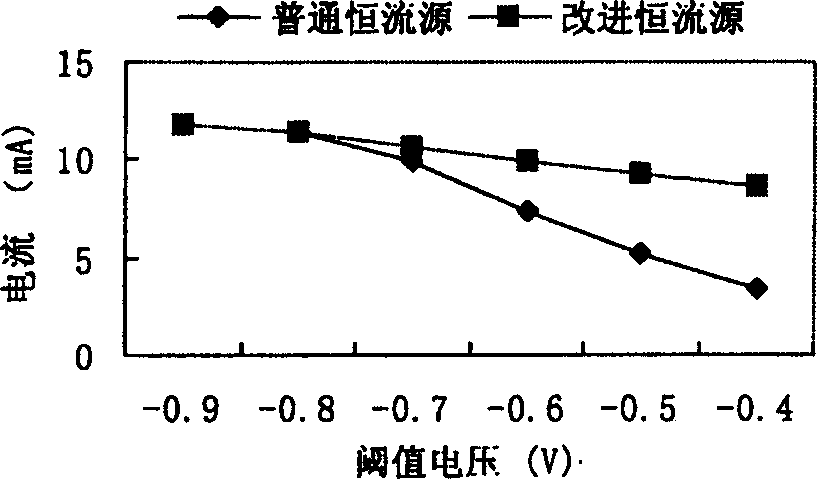

[0022] see figure 2 , the circuit with self-adjusting constant current source of the present invention is as follows figure 2 shown. The main difference between the present invention and the prior art is that the gate sources of all constant current source transistors in the prior art are short-circuited, and the drain current when the gate is zero-biased is used as the constant current current of the differential pair; the present invention The gate of the constant current tube is not directly connected to the source, but the drain current of the constant current tube is controlled by the gate voltage provided by another additional constant current tube gate voltage regulation circuit 3 as the constant current of the differential pair. The laser modulation driving circuit with self-adjusting constant current source includes: a first-stage pre-amplifier circuit 1 (in the prior art), a second-stage pre-amplifier circuit 2 (in the prior art), a constant-current tube grid Vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com