Electrodialysis method for separating sugar and acid in biomass hydrolysate

A hydrolyzate and biomass technology, applied in dialysis, sugar derivatives, sugar derivatives, etc., can solve problems such as difficult use and maintenance, long time, complicated equipment, etc., to reduce power and equipment costs, and increase sugar content , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

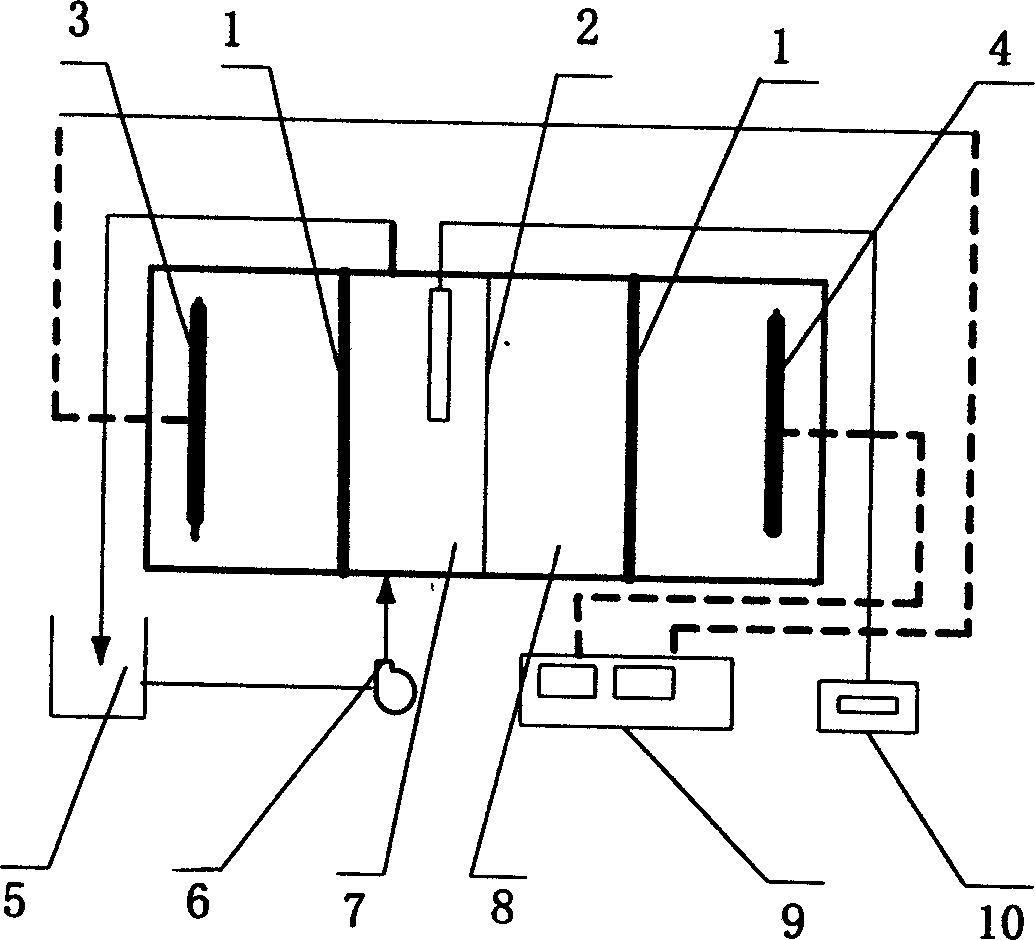

Image

Examples

Embodiment 1

[0020] 500ml of biomass hydrolyzate after vacuum filtration (total sugar mass percentage concentration is 5.82%, hydrochloric acid mass percentage concentration is 1.21%, acetic acid mass percentage concentration is 0.76%), is driven into the treatment chamber by the pump, and the constant flow pump is opened to make the treatment The hydrolyzate in the chamber forms a closed loop, adjusts the output voltage of the DC stabilized source power supply, controls the operating voltage at 45V, and starts the electrodialysis method (the bipolar membrane used is the BP-1E bipolar membrane produced by Japan Tokuyama (Soguyama) Co. Membrane; anion-exchange membrane is the A501SB anion-exchange membrane produced by Japan Asahi Chemical (AsahiChemical) company) separation process of sugar and acid. Use a digital pH meter to measure the pH value of the treatment chamber in real time, and record the operating current regularly. When the pH value of the treatment chamber rises to 5.5, the su...

Embodiment 2

[0022] The operating voltage is 40V, and other process conditions are the same as in Example 1. The operation time of the whole process is 248 minutes, the average current is 1.20A, the recovery rate of acid is 98.5%, and the loss rate of sugar is 2.86%.

Embodiment 3

[0024] The operating voltage is 35V, and other process conditions are the same as in Example 1. The operation time of the whole process was 326 minutes, and the average current was 0.94 A. The acid recovery was 98.5%, and the sugar loss was 3.17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com