Water soluble spherical holing agent and its preparing process and use

A porogen and water-soluble technology, applied in the field of materials, can solve the problems of small channels, inability to prepare large-volume three-dimensional scaffolds, and difficult control of channel shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

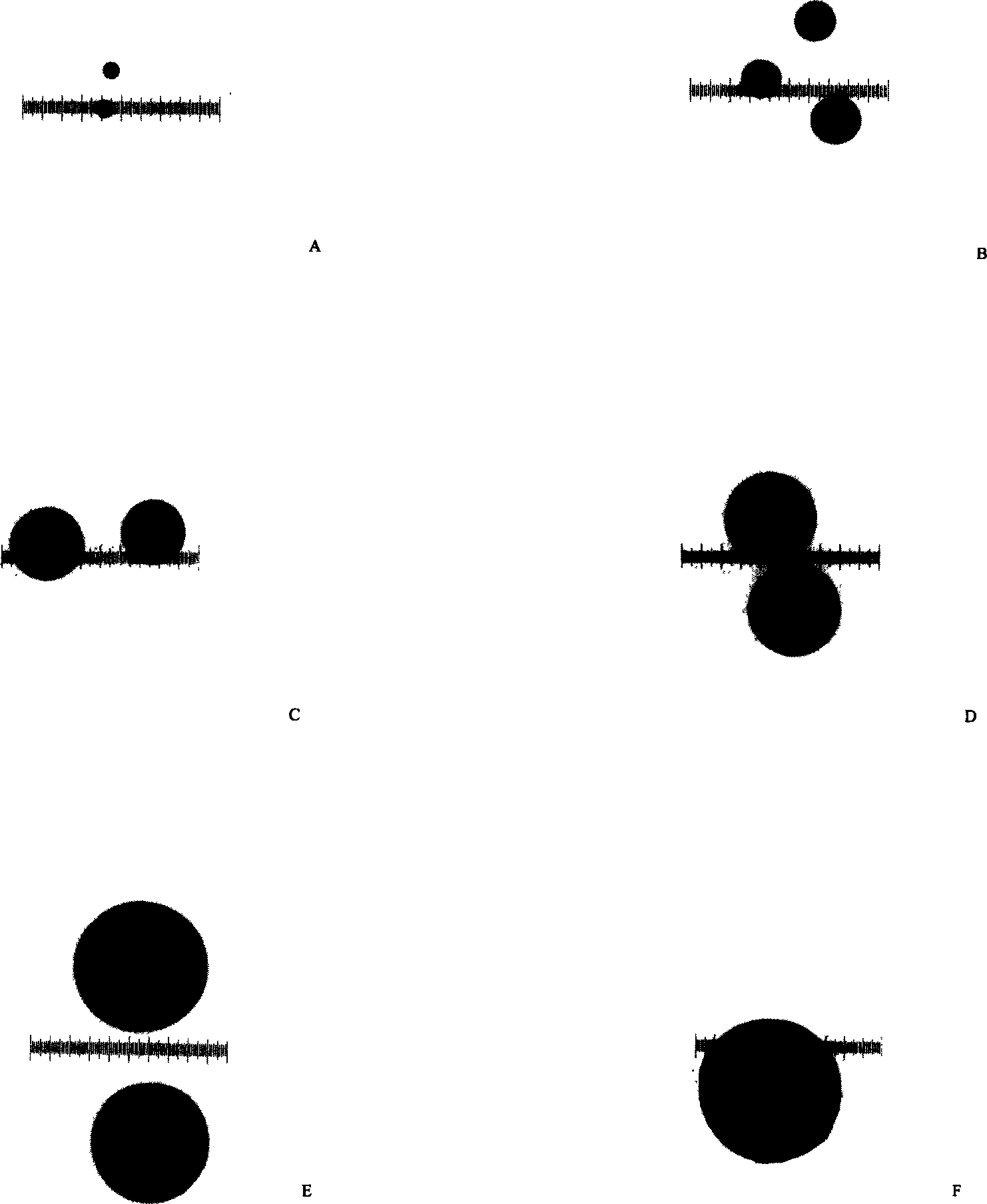

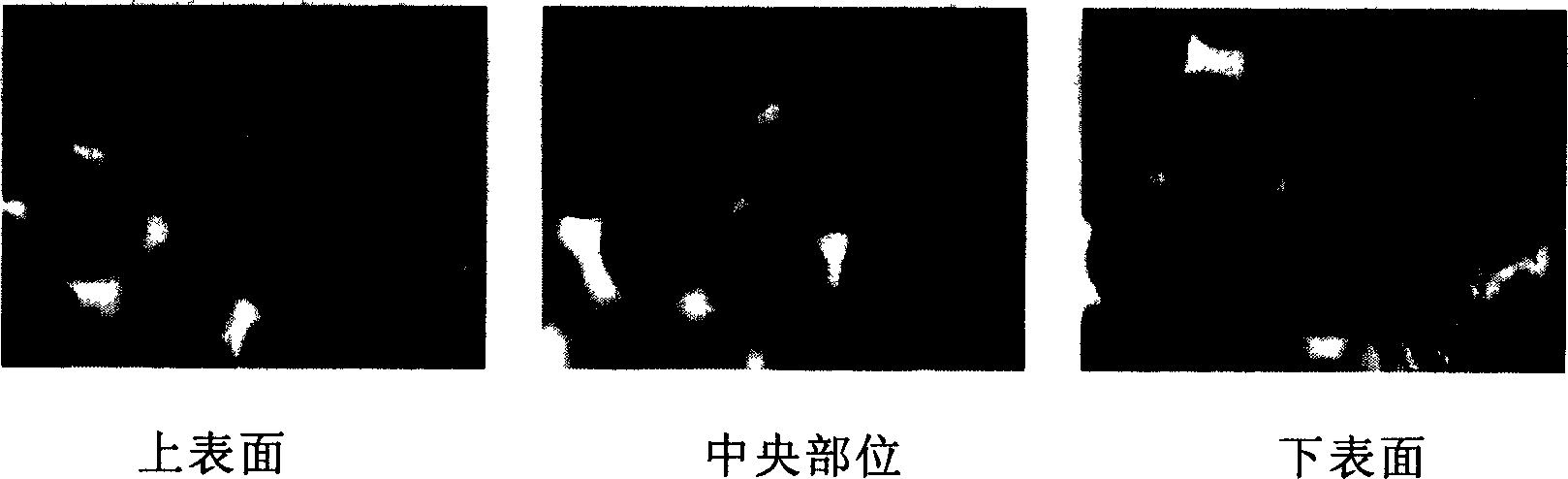

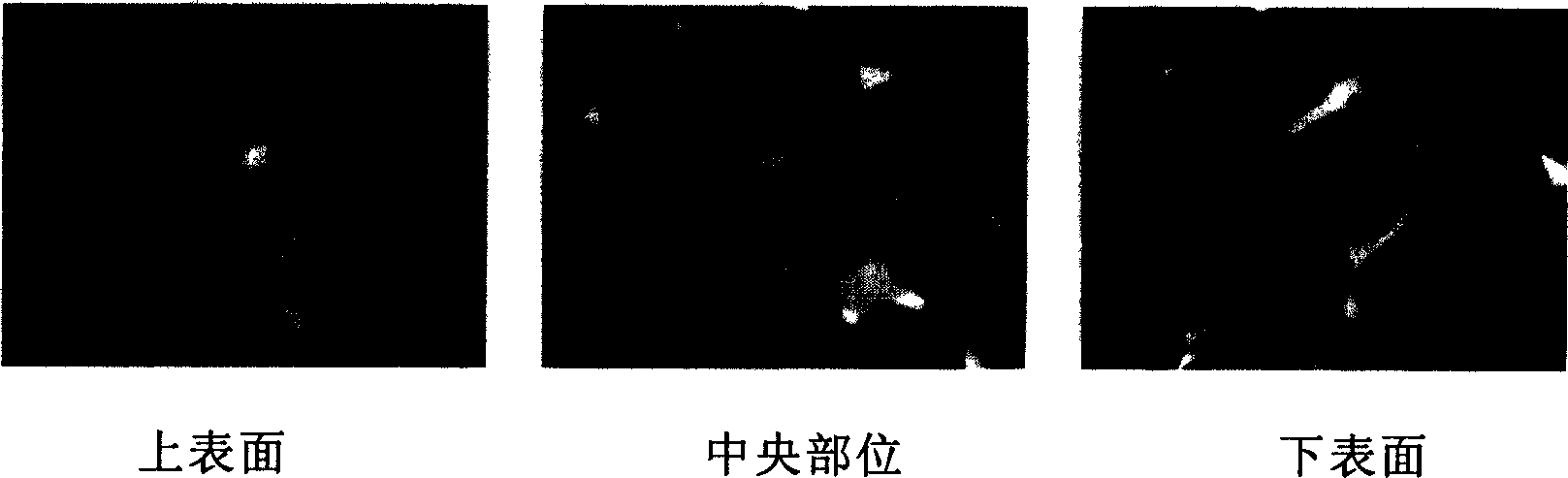

Method used

Image

Examples

preparation example Construction

[0053] The invention provides a method for preparing a spherical water-soluble porogen, which comprises the steps of:

[0054] (a) Mix the porogen raw material with the dispersant to form a mixture

[0055] The selection criteria that can be used for the porogen raw material of the present invention are: the porogen raw material has crystalline properties, good water solubility, suitable hygroscopicity, suitable melting point (preferably lower than 260 degrees), non-toxic or low toxicity , a wide range of sources, low cost, insoluble in organic solvents, relatively stable chemical properties. Suitable porogen raw materials are compounds selected from the group consisting of sodium chlorate, succinimide, urea, sodium thiocyanate, potassium thiocyanate, or mixtures thereof. The melting point of the porogen raw material is T1.

[0056] The dispersant that can be used in the present invention is an organic solvent whose flash point T2 is 50-100° C. higher than the melting point ...

Embodiment 1

[0088] Preparation of spherical porogen (porogen raw material is sodium chlorate)

[0089] 1. In a 500ml beaker, add 400ml H-201 methyl silicone oil (flash point greater than 300°C, specific gravity 0.96-0.975 / 25°C, viscosity 500cp / 25°C. Purchased from the Affiliated Factory of Hangzhou Normal University) and 10-20g chlorine Sodium acid, place the beaker on a temperature-controlled heating device, and install a mechanical stirring device. Adjust the stirring speed to 200 rpm. Under stirring, slowly heat the methyl silicone oil to 260-270°C [not higher than 280°C], so that the sodium chlorate becomes liquid microspheres; then, keep the stirring speed constant, Slowly cool down to 246°C at a rate of 2°C / min. At this moment, the liquid sodium chlorate microspheres are converted into solid state microspheres, and the stirring is stopped. Sodium chlorate) deposition, the methyl silicone oil in the upper layer is poured off, and the spherical porogen can be obtained by suction filt...

Embodiment 2

[0095] Preparation of spherical porogen (porogen raw material is succinimide)

[0096] The steps of Example 1 were repeated, except that 10-20 grams of succinimide was used to replace sodium chlorate, and the heating temperature was 130-140° C.

[0097] After drying the spherical porogen, sieve the sample with a sieve with a pore size of 600 μm, 450 μm, 355 μm, 220 μm and 100 μm to obtain a diameter of 600μm spherical porogen, sealed and stored in a desiccator.

[0098] As a result, spherical porogens with a diameter of 100-600 microns were also obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com