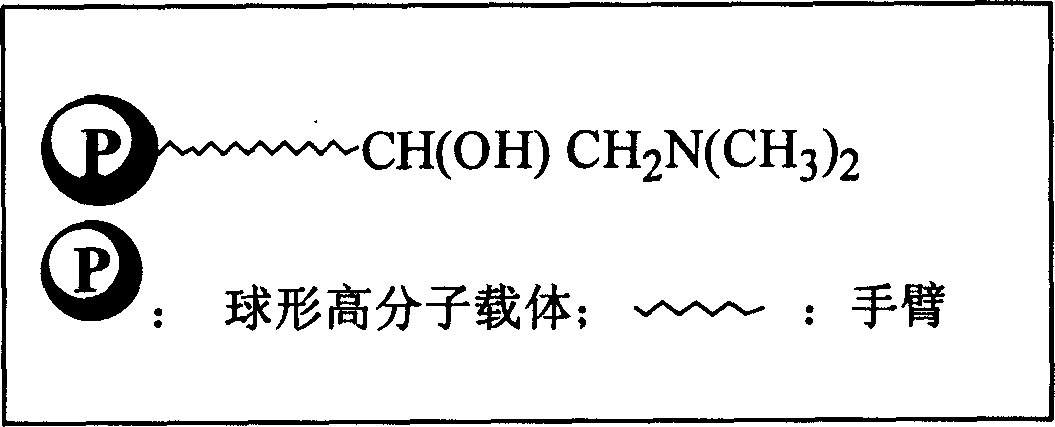

Endotoxin adsorbing agent and preparing method thereof

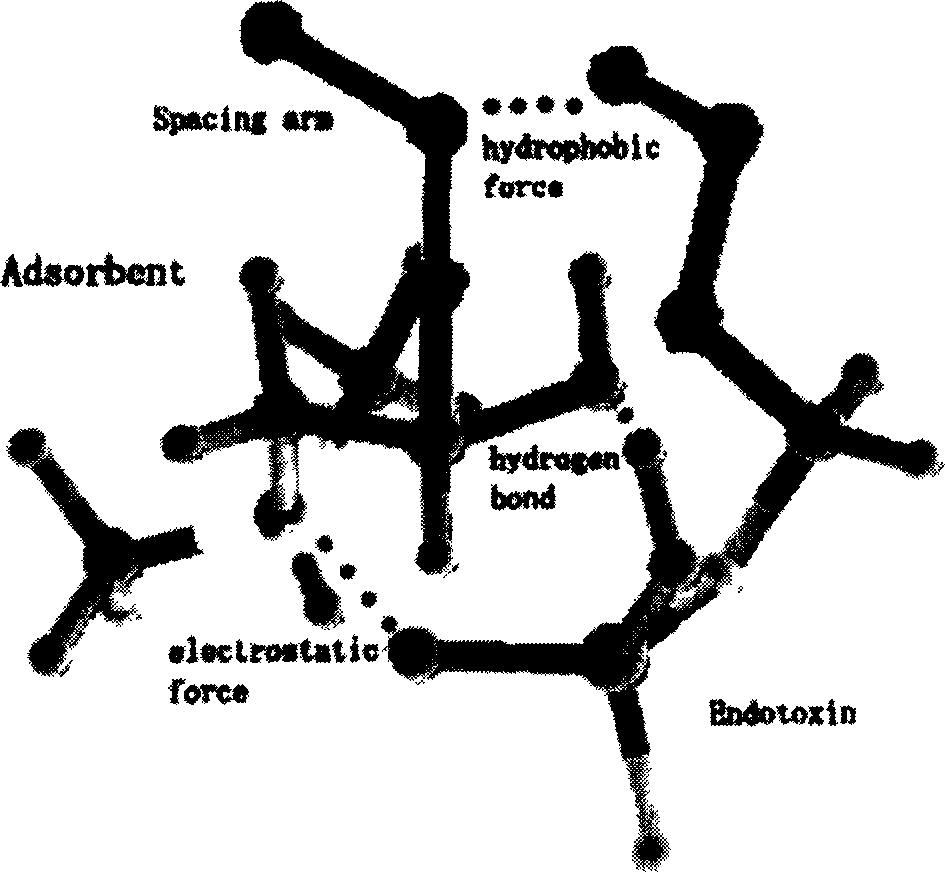

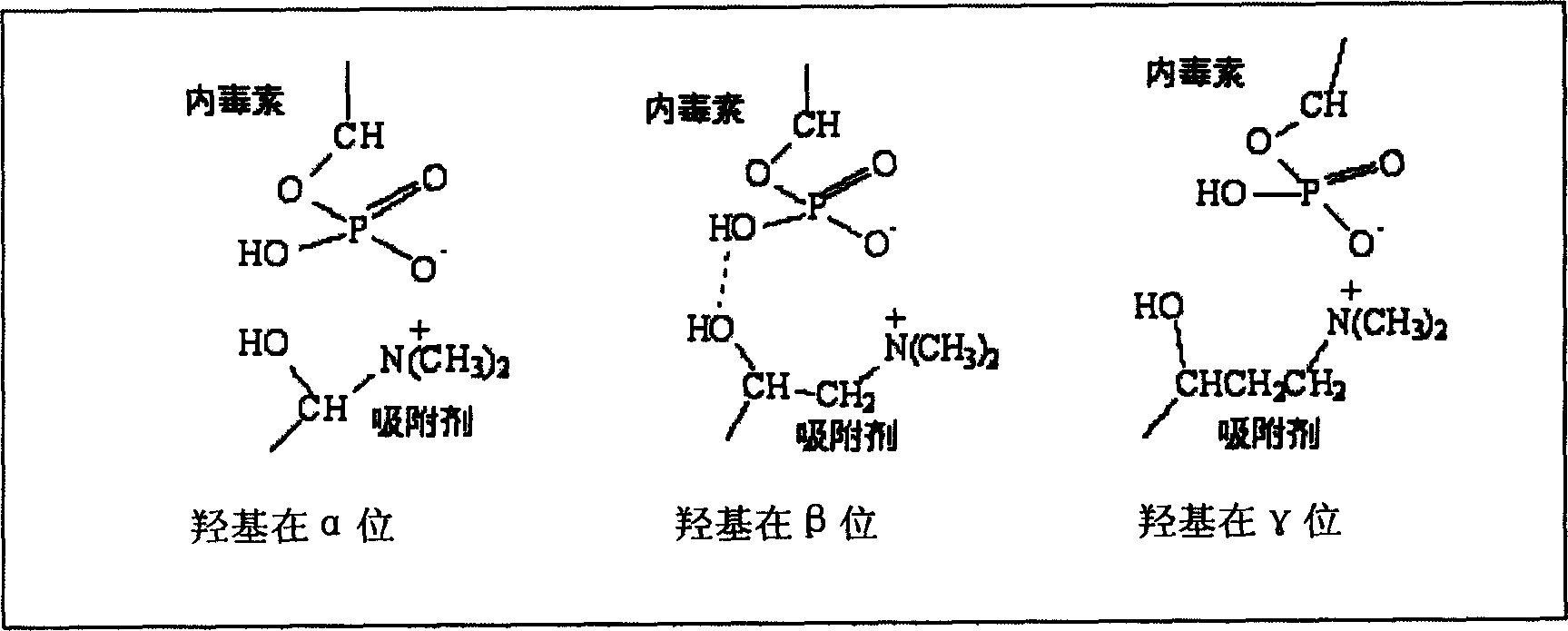

An adsorbent and endotoxin technology, applied in the fields of biochemical separation and biomedical materials, can solve the problems of polymyxin B, which is expensive, nephrotoxic, unsuitable for promotion, toxic and side effects, etc., and achieves high recognition ability, adsorption capacity, and low cost Low, less toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1-1 Preparation of polymethacrylate carrier

[0054] In a three-neck flask equipped with a stirrer, a reflux condenser, and a thermometer, 8.1 g of methyl methacrylate containing 0.414 g of benzoyl peroxide and 18.8 g of divinylbenzene mixed solution were added to a mixture containing 20% chlorinated Add 5-8 drops of 0.1% methylene blue to the aqueous phase (2-4 times the volume of the organic phase) of sodium and 0.5% gelatin. Adjust the stirring speed until the size of the liquid beads is suitable and the particle size is uniform, then raise the temperature to 67°C, and polymerize for two hours; then raise the temperature to 75°C, and polymerize for two hours; then raise the temperature to 85°C, and polymerize for two hours; then raise the temperature to 95°C, and keep the temperature for four hours Hours, the carrier PMMA was prepared. Repeated scrubbing with hot water, extraction with absolute ethanol for 8 hours, drying, and sieving to collect carriers with a pa...

Embodiment 2

[0090] 2-1 Preparation of Chitosan Resin

[0091] To 5% chitosan acetic acid aqueous solution (5g chitosan+3ml glacial acetic acid+100ml water), add 1g Span 80 dissolved in 300ml toluene solution, and stir for 1.5 hours. 50ml of 50% glutaraldehyde aqueous solution was slowly added dropwise, the temperature was raised to 50°C, and the temperature was kept constant for 1.0 hour. Aqueous sodium hydroxide solution was added to adjust the pH of the reaction system to be slightly alkaline. Raise the temperature to 80°C and keep the temperature constant for 4 hours. The product is extracted with absolute ethanol, washed with water, weighed, and sieved to collect the carrier with a particle size of 280-900 μm. NaBH under alkaline conditions at room temperature 4 Restore for 24 hours, wash and set aside. The content of remaining amino groups was measured by acid-base titration method to be 101.3-120.7 μmol / g.

[0092] 2-1 Epoxy Activation

[0093] Add 1g of chitosan resin, 5ml of...

Embodiment 3

[0101] 3-1 Preparation of spherical agar carrier

[0102] Place a 500ml three-necked flask in a 60°C water bath, add 100ml of toluene, 50ml of carbon tetrachloride, and 0.5ml of Tween 80 into the bottle, and stir evenly. Weigh 4 grams of agar powder and add 30ml of distilled water, heat and melt, pour the melted agar into the toluene-carbon tetrachloride system, stir, and disperse the agar solution into droplets of suitable size in the organic phase. Cool to room temperature, pour out the organic solvent in the upper layer, screen the agar balls with a particle size of 280-900 μm, wash with water, transfer to an Erlenmeyer flask, and store in a wet state at 4°C.

[0103] 3-2 Epichlorohydrin activation

[0104] Take 20.0 grams of agar balls, add 29.6 milliliters of 2M sodium hydroxide, then add 13.3 milliliters of epichlorohydrin, react at 40 ° C for 2 hours, wash with water until neutral, and thoroughly wash off the remaining epichlorohydrin, Epoxy-activated gel balls were o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com