Purification agent for decolour in making sugar, purification method for declour of sugar juice and technology for directing producing fine white sugar thereof

A detergent and decolorization technology, which is applied in sucrose production, sugar production, sugar juice purification, etc., can solve the problems of post-process influence, inconvenient operation, and high price, so as to improve the quality of sugar products and achieve good removal effect , The effect of light decolorization burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1 Preparation of sugar decolorizing detergent containing high molecular weight aluminum polymer

[0083] Raw material preparation:

[0084] (1) Metal aluminum: There is no limit to the shape and specification, mostly in block shape, with a purity of 97% or more.

[0085] (2) Metal mixture: a small amount of iron powder, zinc powder, manganese powder, copper powder, mercury.

[0086] (3) Hydrochloric acid: qualified product.

[0087] (4) Sodium sulfide (industrial grade)

[0088] (5) Activated carbon powder (industrial grade)

[0089] step:

[0090] (1) Manually wipe off the oxide layer on the surface of the aluminum block, subject to the nature of the aluminum.

[0091] (2) The aluminum block from which the surface oxide layer is removed is completely immersed in a 0.5-6N HCl solution for 30 seconds. A large number of bubbles are generated on the surface of the aluminum block to activate the aluminum block.

[0092] (3) Place the activated aluminum block in the meta...

Embodiment 2

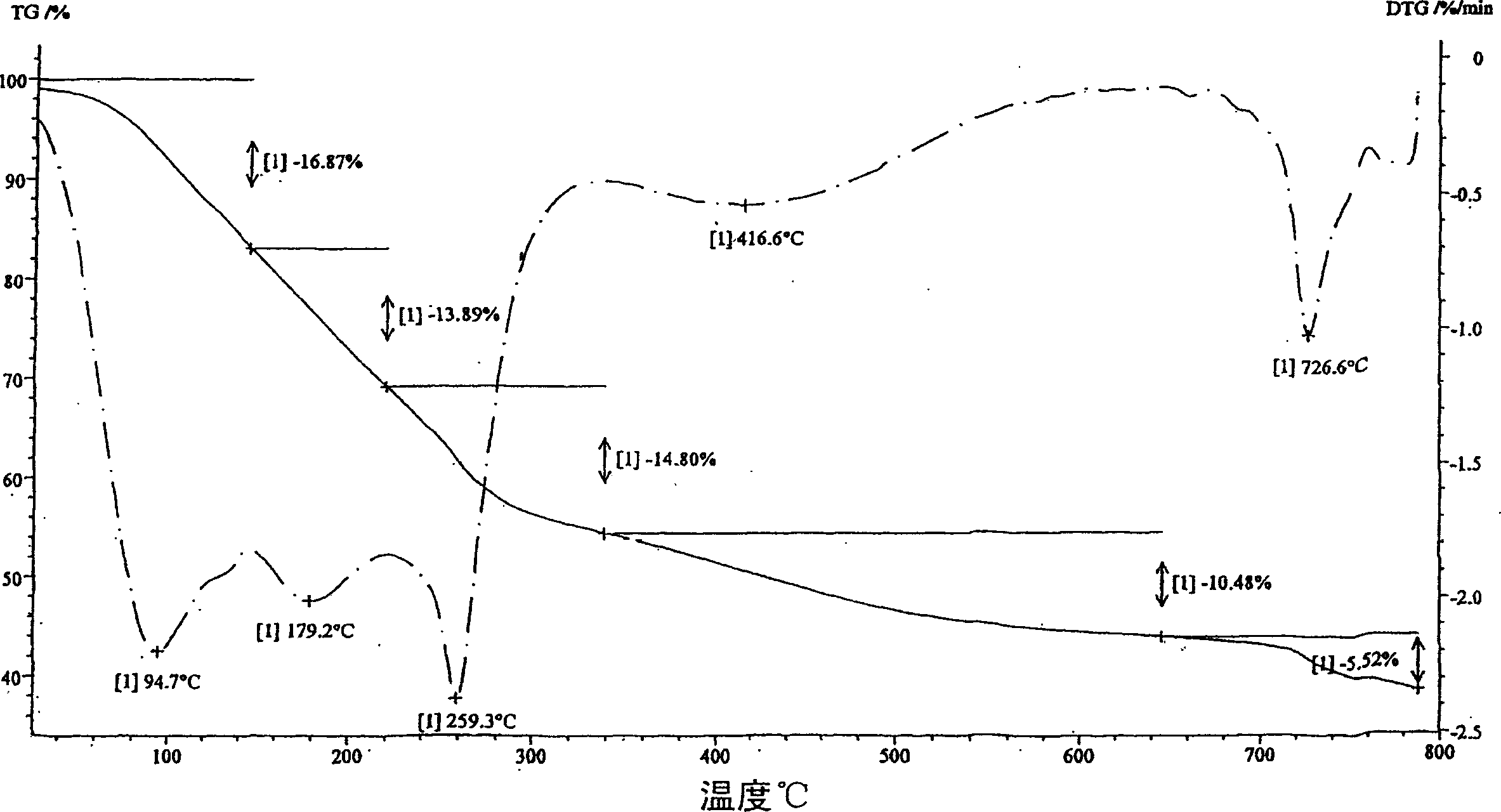

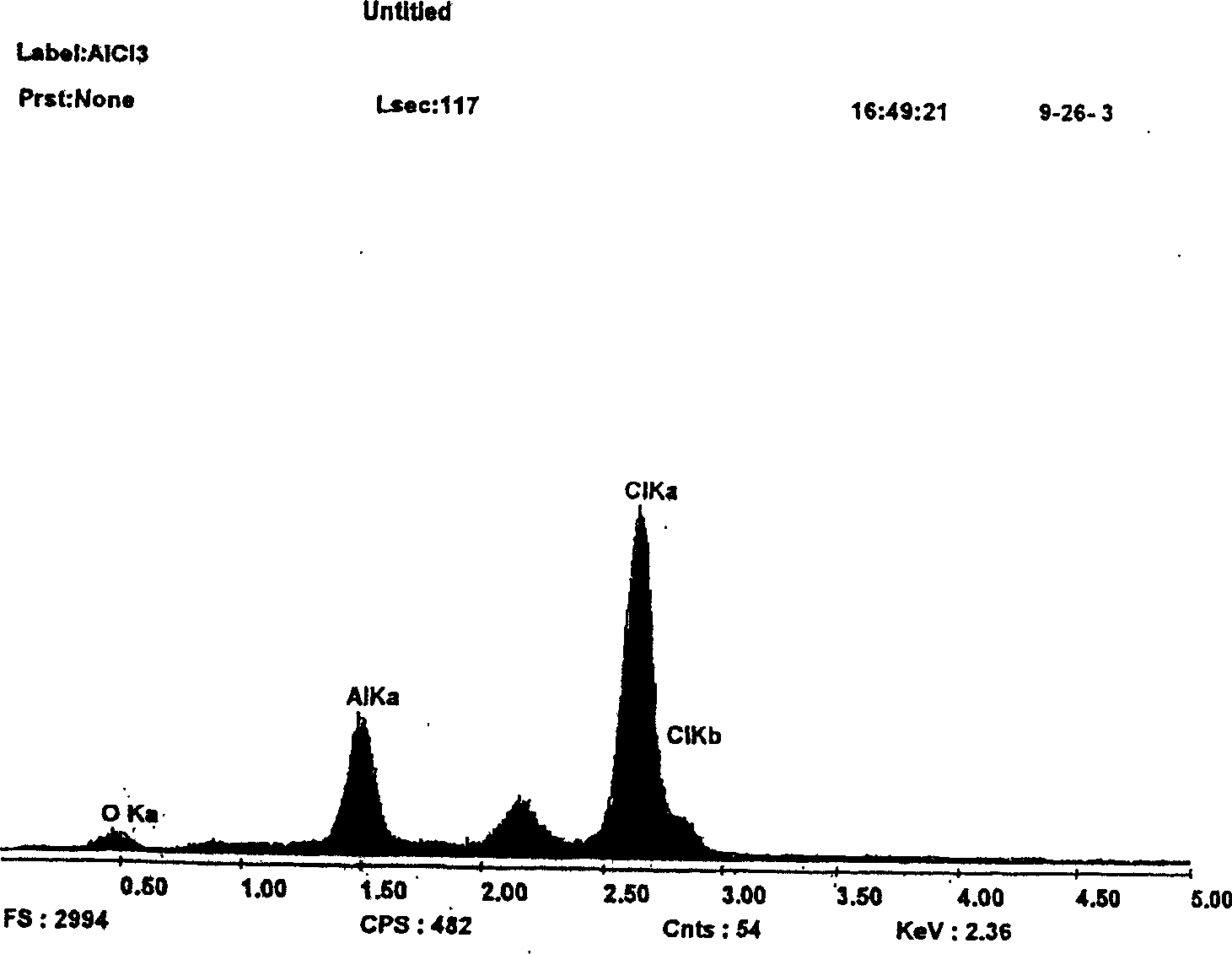

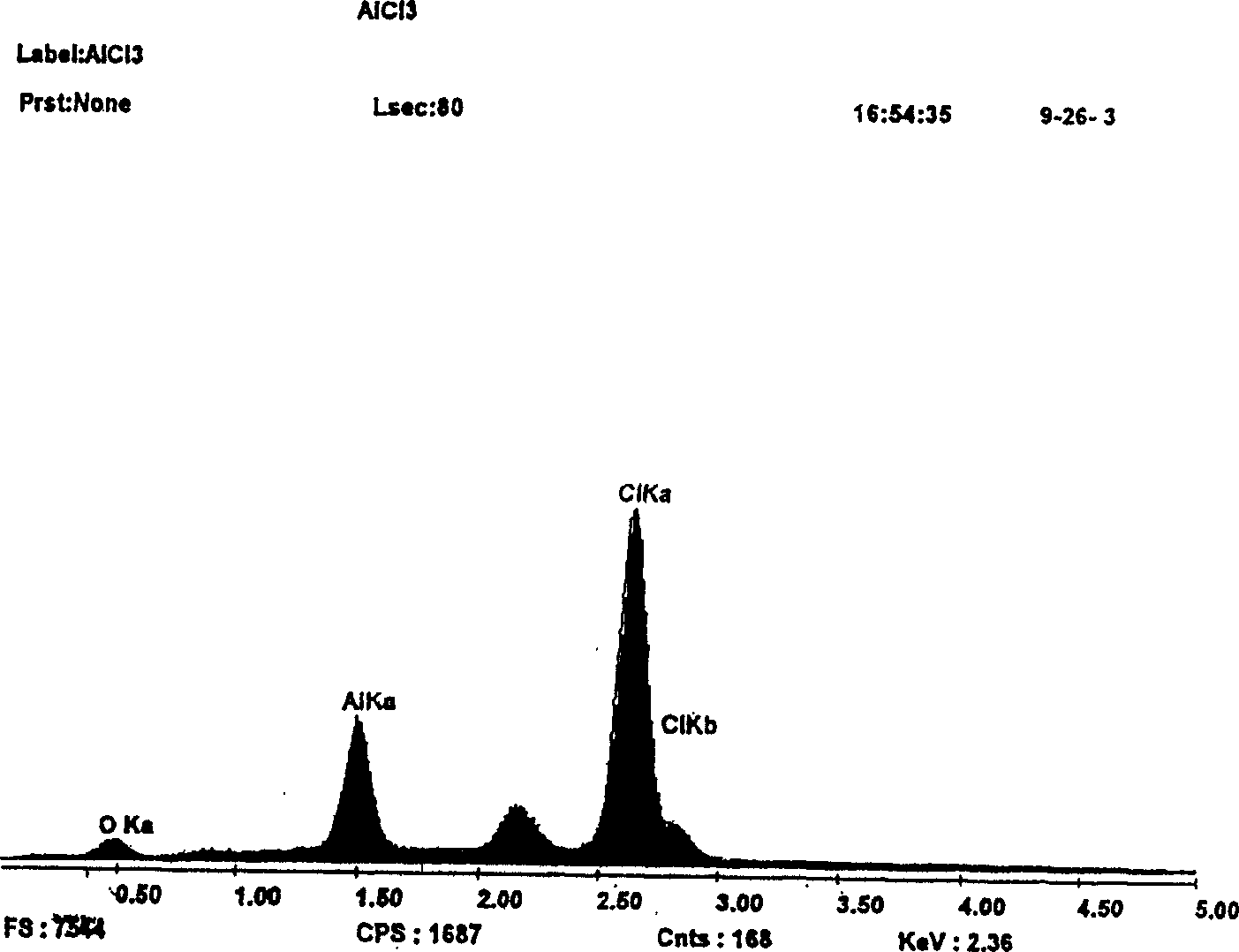

[0098] Example 2 Molecular weight analysis of high molecular weight aluminum polymer

[0099] Method: NMR spectrum analysis combined with scanning electron microscopy

[0100] result:

[0101] 1. NMR spectrum analysis

[0102] Sample: one part each of the white powder and colorless transparent liquid prepared in Example 1

[0103] Apparatus and test method: Superconducting nuclear magnetic resonance spectrometer AVANCE 400digital NMR from Bruker, Germany. 27 Al resonance frequency is 104.26MHz, measured with CP / MAS probe 27 Al solid spectrum, multi-core probe BBO measurement 27 Al liquid spectrum, the reference is 1M AlCl aqueous solution.

[0104] The measurement results:

[0105] (1) Example 1 CP / MAS of solid powder 27 Al-NMR spectrum: The influence of rotating sidebands is taken from this spectrum at different speeds (3K, 5K, 7K). It can be seen that the resonance absorption of Al in the two samples at about 2ppm and 69ppm is in line with the polyaluminum chloride The case of t...

Embodiment 3

[0109] Example 3 Preparation and molecular weight distribution of aluminum polymers with different Al:OH:Cl

[0110] Raw materials: see Example 1.

[0111] Step 1 is the same as the above. Step 2 is treated with 5N HCl to control the reaction time. Step 3 is properly treated with a metal mixture. Step 4 uses 2N HCl solution. The ratio of aluminum to hydrochloric acid solution is 1:8. Control the reaction temperature and time until the alumina is consumed. The final product was determined to contain about 60% of polymerized macromolecules or colloidal particles with a molecular weight of more than 50,000, about 40% of polynuclear hydroxyaluminum complexes with a molecular weight of less than 10,000, and no hexahydrate hydrated aluminum particles and mononuclear hydroxyaluminum complexes. The basicity is 90%. It can be made into solid powder as required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com