Method of preparing positive electrode composite material of Lithium ion cell contg, ferrous phosphate lithium salt-carbon

A technology for lithium ferrous phosphate and lithium-ion batteries, which is applied in electrode manufacturing, battery electrodes, phosphorus compounds, etc. It can solve the problems of difficult control of product purity, complicated preparation process, and high price, and achieve excellent cycle performance and high purity. , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix 0.5 mole of lithium hydroxide and 0.5 mole of iron phosphate, put it into a nylon tank, and add 80ml of alcohol, mix it on a ball mill for 2 hours, then blend the mixture into 14 grams of polypropylene and put it in a tube furnace, and heat it at 5 Under a nitrogen atmosphere of 1 / min, the temperature was raised to 700°C at a rate of 5°C / min, kept at this temperature for 10 hours, and then cooled to room temperature.

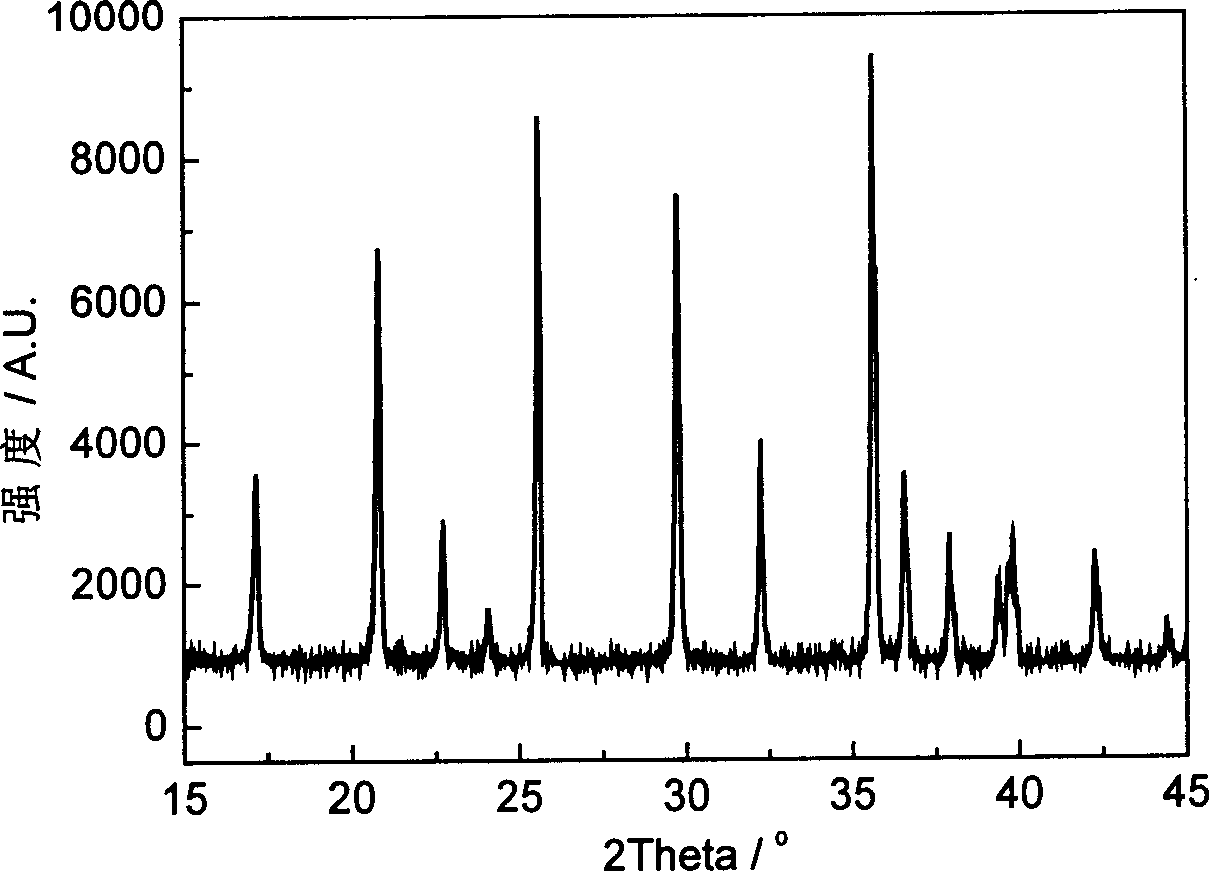

[0019] The measured carbon content in the resulting composite material is 2.5%, and its XRD spectrum is shown in figure 1 , compared with the standard card, it is olivine LiFePO with intact crystal form 4 , while no carbon diffraction peak was observed.

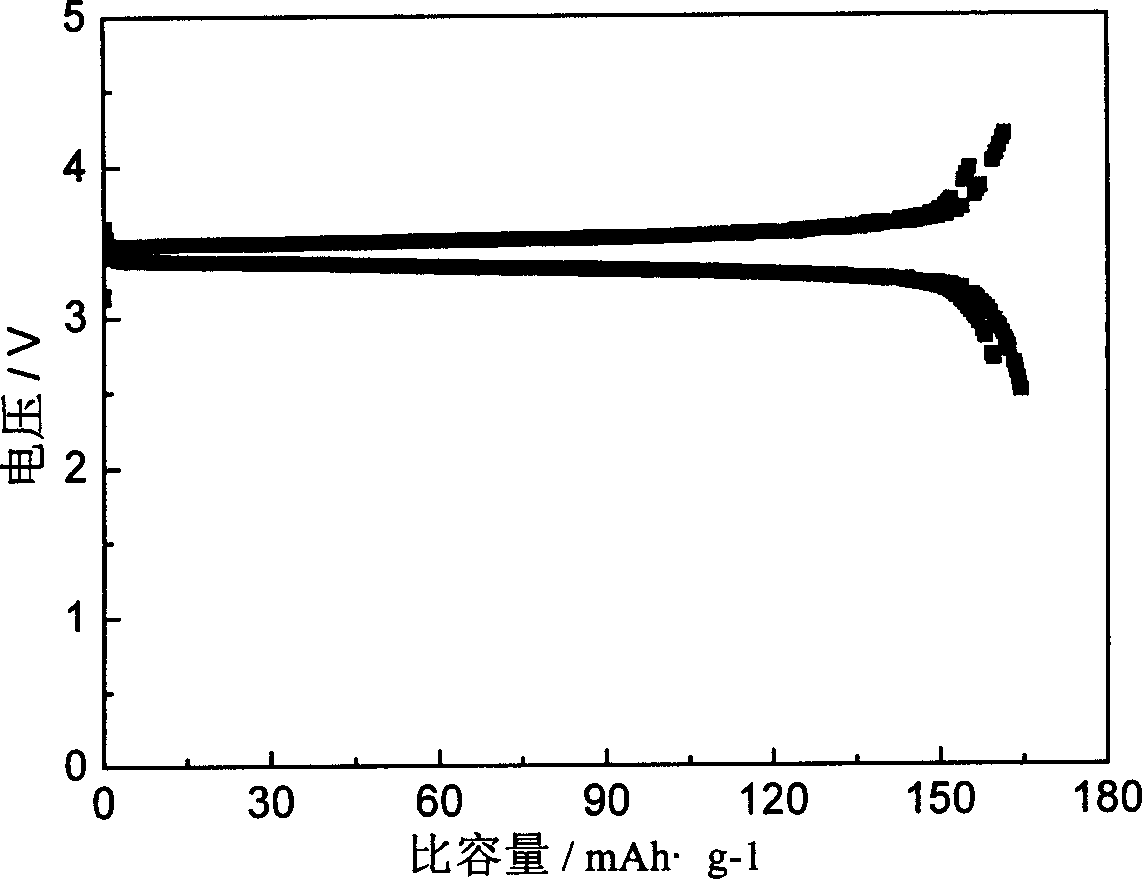

[0020] Using the composite material obtained in Example 1, an electrode was prepared in the following manner.

[0021] Take the composite material obtained in Example 1 at a mass ratio of 80: 10: 10: carbon black: polytetrafluoroethylene, and grind it evenly to make an electrode. 1.0mol / L LiPF in ...

Embodiment 2

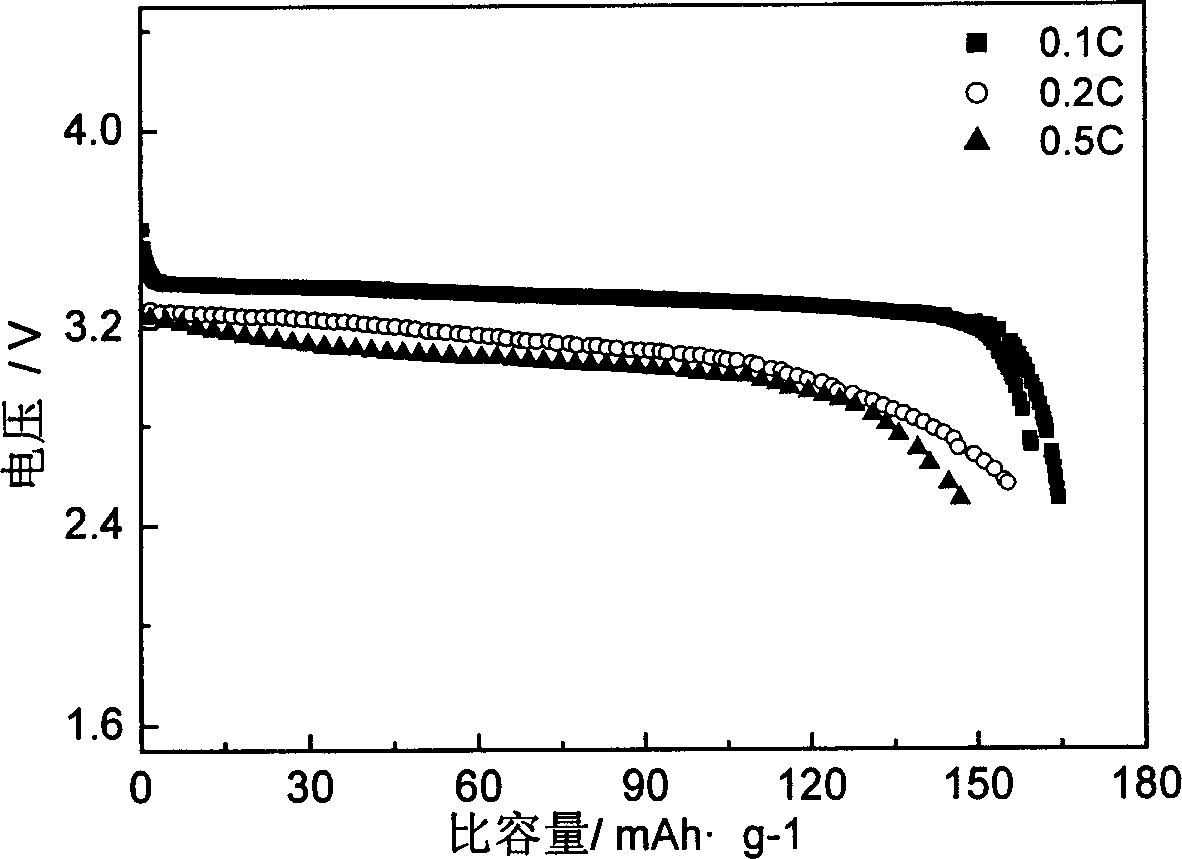

[0023] Mix 0.5 moles of lithium hydroxide, 0.25 moles of ferric oxide and 0.5 moles of ammonium dihydrogen phosphate and put them into a nylon tank, add 80ml of alcohol, mix well on a ball mill for 2 hours, then blend the mixture into 20 grams The polypropylene was placed in a tube furnace, and was raised to 700°C at a rate of 5°C / min under a nitrogen atmosphere of 5 liters / min, and kept at this temperature for 20 hours, and then cooled to room temperature. The carbon content of the obtained composite material was measured to be 4.6%. The electrode sheet was also prepared according to the method of Example 1. After being assembled into a battery, it was charged and discharged at a rate of 0.2C. The measured reversible capacity was 157mAh / g.

Embodiment 3

[0025] Mix 0.5 mole of lithium hydroxide and 0.5 mole of iron phosphate, put it in a nylon tank, and add 80ml of alcohol, mix it on a ball mill for 1 hour, then mix the mixture with 25 grams of polyethylene and put it in a tube furnace. Under a nitrogen atmosphere of liters / min, the temperature was raised to 500°C at a rate of 5°C / min, kept at this temperature for 24 hours, and then cooled to room temperature. The carbon content of the obtained composite material was measured to be 3.1%, and the electrode sheet was prepared according to the method of Example 1. After being assembled into a battery, it was charged and discharged at a rate of 0.5C, and the measured reversible capacity was 148mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com