Composite and prepn process of electronic ceramic material with superhigh temperature stability

A technology of electronic ceramics and ceramic materials, which is applied in the field of functional ceramic materials and its manufacturing, can solve the problems of inability to provide dielectric properties, and achieve the effects of good market prospects, high dielectric constant, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

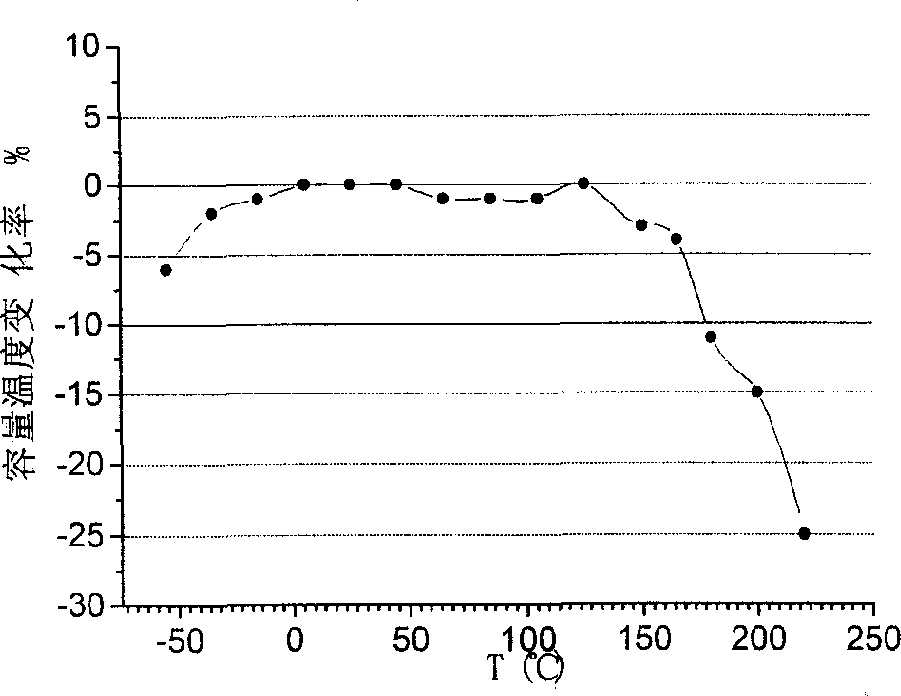

Embodiment 1

[0020] Analytical pure B 2 o 3 , PbO, Bi 2 o 3 , SnO 2 、TiO 2 For raw materials according to B 2 o 3 22g, PbO9g, Bi 2 o 3 26g, SnO 2 3g, TiO 2 11g was mixed and melted, that is, the temperature was raised to 900°C at a rate of 6°C / min and kept for 8 hours, then quenched and cooled with ZrO 2 Ball milling with deionized water for 15 hours, drying in an electric oven at 120°C and passing through a 40-mesh sieve to obtain self-made additives; 3 , niobium oxide and magnesium oxide and BaCO 3 and self-made additives as raw materials according to BaTiO 3 96g, Nb 2 o 5 1.7g, MgO 0.6g, BaCO 3 1.1g, additive 17g ratio mixed, with ZrO 2 Ball milling with deionized water for 10 hours, drying in an electric oven at 120°C, adding paraffin, passing through an 80-mesh sieve, pressing under a pressure of 80MPa to form a disc-shaped green body with a diameter of about 20mm and a thickness of about 1mm, and then sintering. That is, after raising the temperature to 500° C. at...

Embodiment 2

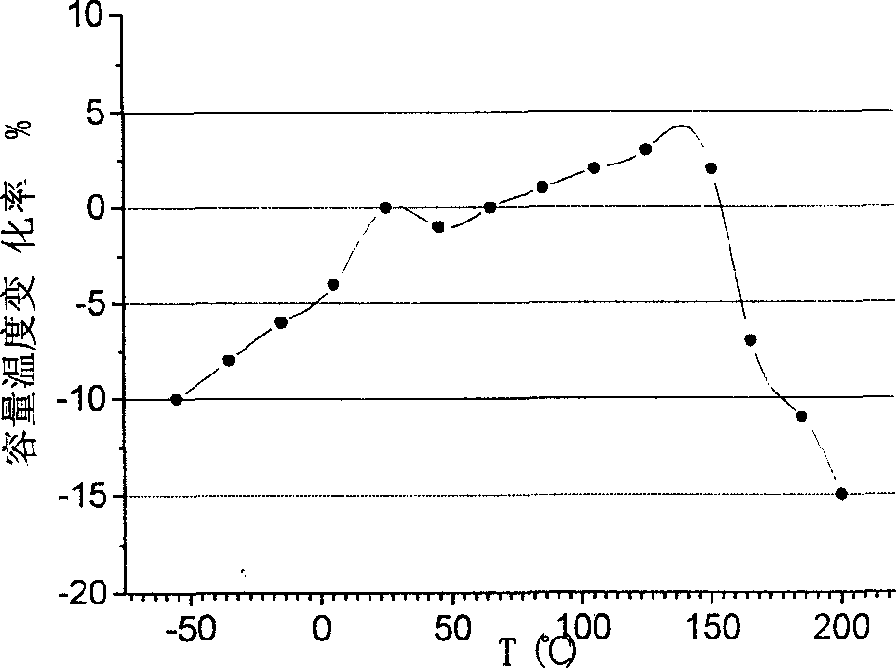

[0023] Analytical pure B 2 o 3 , PbO, Bi 2 o 3 , SnO 2 、TiO 2 For raw materials according to B 2 o 3 24g, PbO14g, Bi 2 o 3 15g, SnO 2 4g, TiO 2 12g was mixed and melted, that is, the temperature was raised to 900°C at a rate of 6°C / min and kept for 9 hours, then quenched, and ZrO 2 Ball milling with deionized water for 15 hours, drying in an electric oven at 120°C and passing through a 40-mesh sieve to obtain self-made additives; 3 , niobium oxide and magnesium oxide and BaCO 3 and self-made additives as raw materials according to BaTiO 3 96g, Nb 2 o 5 1.7g, MgO 0.6g, BaCO 3 1.5g, additive 14g ratio mixed, with ZrO 2 Ball milling with deionized water for 10 hours, drying in an electric oven at 120°C, adding paraffin, passing through an 80-mesh sieve, pressing under a pressure of 80MPa to form a disc-shaped green body with a diameter of about 20mm and a thickness of about 1mm, and then sintering. That is, after raising the temperature to 500° C. at a heating...

Embodiment 3

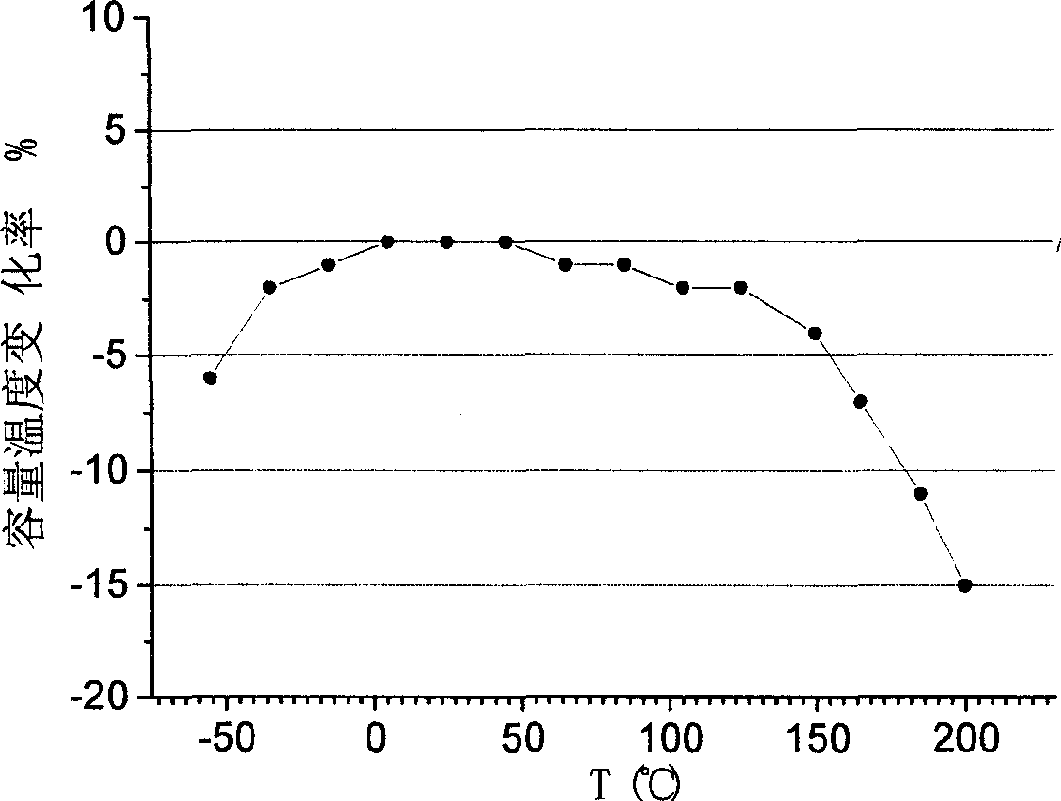

[0027] Analytical pure B 2 o 3 , PbO, Bi 2 o 3 , SnO 2 、TiO 2 For raw materials according to B 2 o 3 24g, PbO9g, Bi 2 o 3 5g, SnO 2 4g, TiO 2 9g was mixed and melted, that is, the temperature was raised to 900°C at a rate of 6°C / min and kept for 3 hours, then quenched and cooled with ZrO 2 Ball milling with deionized water for 15 hours, drying in an electric oven at 120°C and passing through a 40-mesh sieve to obtain self-made additives; 3 , niobium oxide and magnesium oxide and BaCO 3 and self-made additives as raw materials according to BaTiO 3 95g, Nb 2 o 5 2g, MgO 0.6g, BaCO 3 1.1g, additive 13g ratio mixed, with ZrO 2 Ball milling with deionized water for 5 to 15 hours, drying in an electric oven at 120°C, adding paraffin, passing through an 80-mesh sieve, pressing under a pressure of 80MPa to form a disc-shaped green body with a diameter of about 20mm and a thickness of about 1mm, and then Sintering, that is, after raising the temperature to 500° C. at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com