Radiation-sensitive resin composition, patterned resin film, method for formation of the film, and use thereof

A resin composition and sensitive technology, applied in the field of forming resin pattern films, can solve the problems of low productivity, inability to obtain heat discoloration resistance, inability to maintain transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] Hereinafter, the present invention will be described more concretely with reference to synthesis examples, examples, and comparative examples. "Parts" and "%" in each example are based on mass (weight basis) unless otherwise specified.

Synthetic example 1

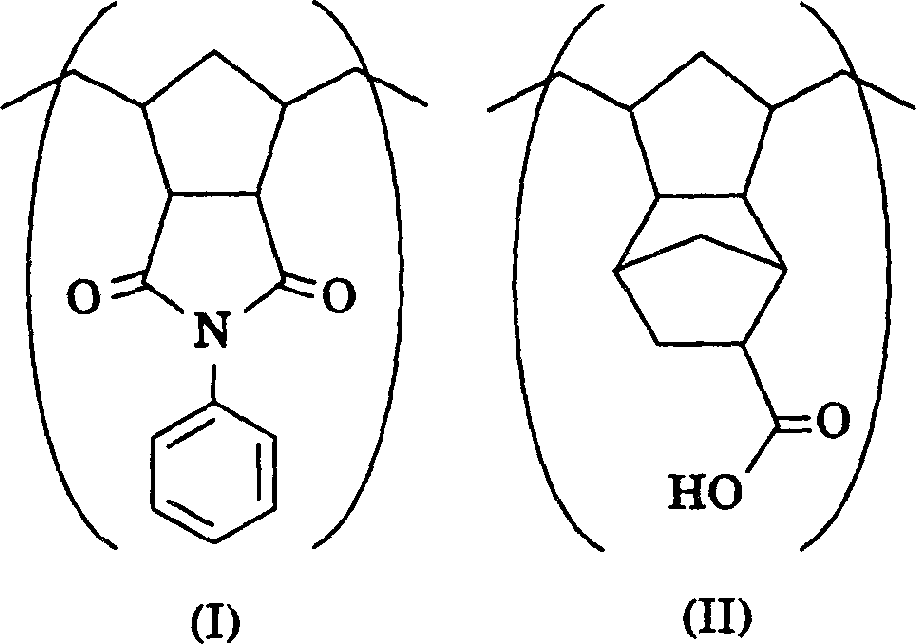

[0097] 8-methyl-8-methoxycarbonyltetracyclo[4.4.0.1 as an alicyclic olefin monomer 2,5 .1 7,10 ] 60 parts of dodec-3-ene, 40 parts of N-phenyl-(5-norbornene-2,3-dicarboxyimide), 72 parts of 1-hexene and 300 parts of toluene, add nitrogen gas In the reaction vessel, after heating to 60°C, add 0.248 parts of triethylaluminum 1.5 mol / liter toluene solution and modify under the condition of tert-butanol / methanol / tungsten=0.25 / 0.3 / 1 (molar ratio) WCl 6 3.7 parts of the solution (0.05 mol / liter) were stirred at 80° C. for 3 hours to perform ring-opening polymerization to obtain a ring-opened copolymer having a weight average molecular weight of 17,000. The polymerization conversion was about 100%.

[0098] Then, 1,000 parts of the obtained ring-opening copolymer solution was added to the autoclave, and RuHCl(CO)[P(C 6 h 5 ) 3 ] 19.5 parts, then add the air pressure to be 100Kg / cm 2 hydrogen gas, while stirring at a reaction temperature of 165° C. for 3 hours to carry out a hy...

Synthetic example 2

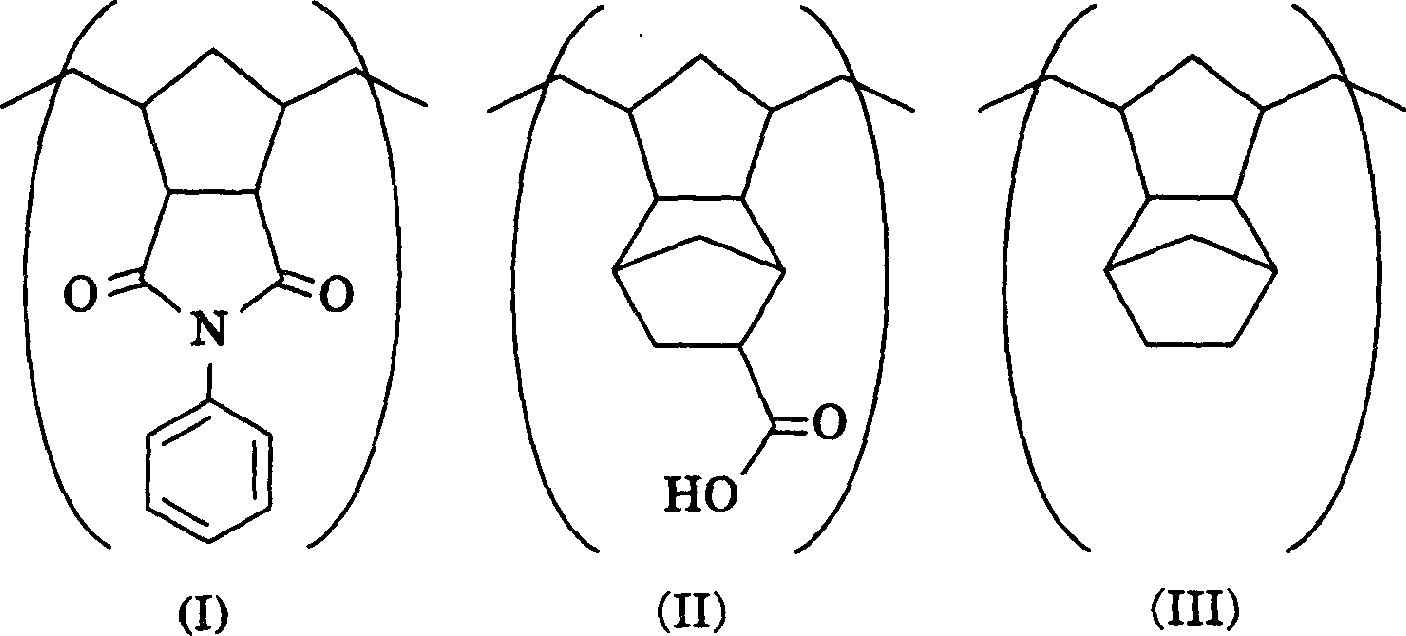

[0104] In addition to the composition of the alicyclic olefin monomer becomes 8-methyl-8-methoxycarbonyl tetracyclic [4.4.0.1 2,5 .1 7, 10 ] 70 parts of dodec-3-ene, 20 parts of N-phenyl-(5-norbornene-2,3-dicarboxyimide) and tetracyclo[4.4.0.1 2,5 .1 7,10 ] Except for 10 parts of dodec-3-ene, the others are the same as in Synthesis Example 1. After the ring-opening polymerization, the overlapping conversion rate is about 100%, the weight average molecular weight is 21,100, the hydrogen addition rate is 100%, and the hydrolysis rate is 97%. % of cycloaliphatic olefin resin (polymer A2).

[0105] This polymer A2, after 1 H-NMR spectrum analysis confirmed that it was a substance having repeating units (I), (II) and (III) represented by the following formulae.

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com