Preparation of oligose from alpha-L-arabglycosidase

A technology of arabinosidase and xylooligosaccharides, which is applied in the field of preparation of xylooligosaccharides by α-L-arabinosidase, which can solve the problems of affecting the efficiency of enzymatic hydrolysis, inability to combine and decompose, and affecting the quality of xylooligosaccharides , to achieve the effect of improving quality and purity, increasing content, and increasing xylobiose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: (1) get the air-dried corn cob fiber that particle diameter is about 3mm, centrifugally remove moisture after soaking with clear water earlier, add sodium hydroxide solution by solid-liquid ratio 7~10: 1, final concentration is 1%~3 %, leaching at room temperature or high temperature, then collecting the filtrate and neutralizing it to slightly acidic with acid, and then precipitating with three times the volume of ethanol to obtain xylan.

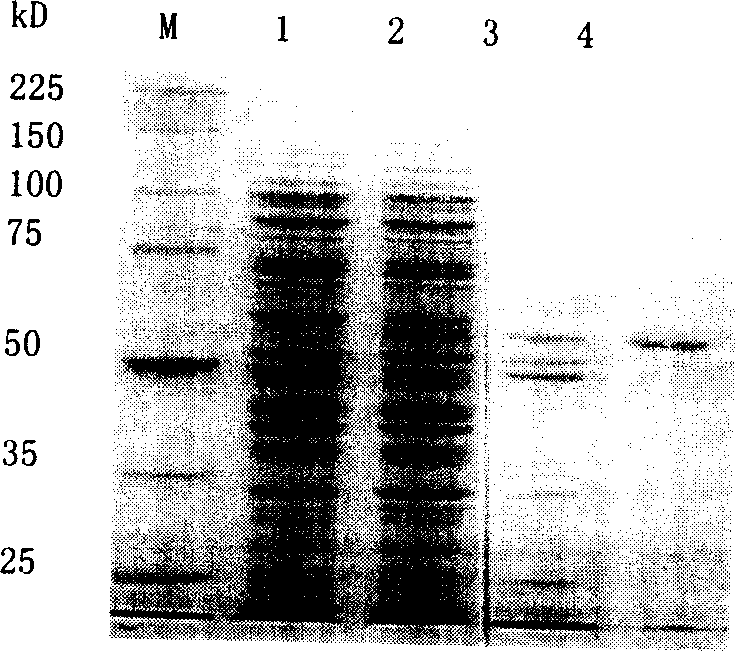

[0027] (2) Preparation of heat-resistant enzyme

[0028]Two pairs of primers were designed according to the sequences of xynB and ara in Genbank, and the genomic DNA of T. maritima was used as a template for PCR amplification. The Tm-xymB-N-terminal primer is (5'-CCGTTCCATGGACTACAGGATGTGC-3'), and the Tm-xymB-C-terminal primer is (5'-CCGCTCGAGCGGATATATCTTTTCTTCCCTT-3'). Tm-ara-N: 5-GGGGGTACCATGTCCTACAGGATAGTG-3 with EcoRV restriction site and start codon; Tm-ara-C: 5-AACTGCAGTCACTCGAGCAATTCTACCTCAAT-3 with an XhoI res...

Embodiment 2

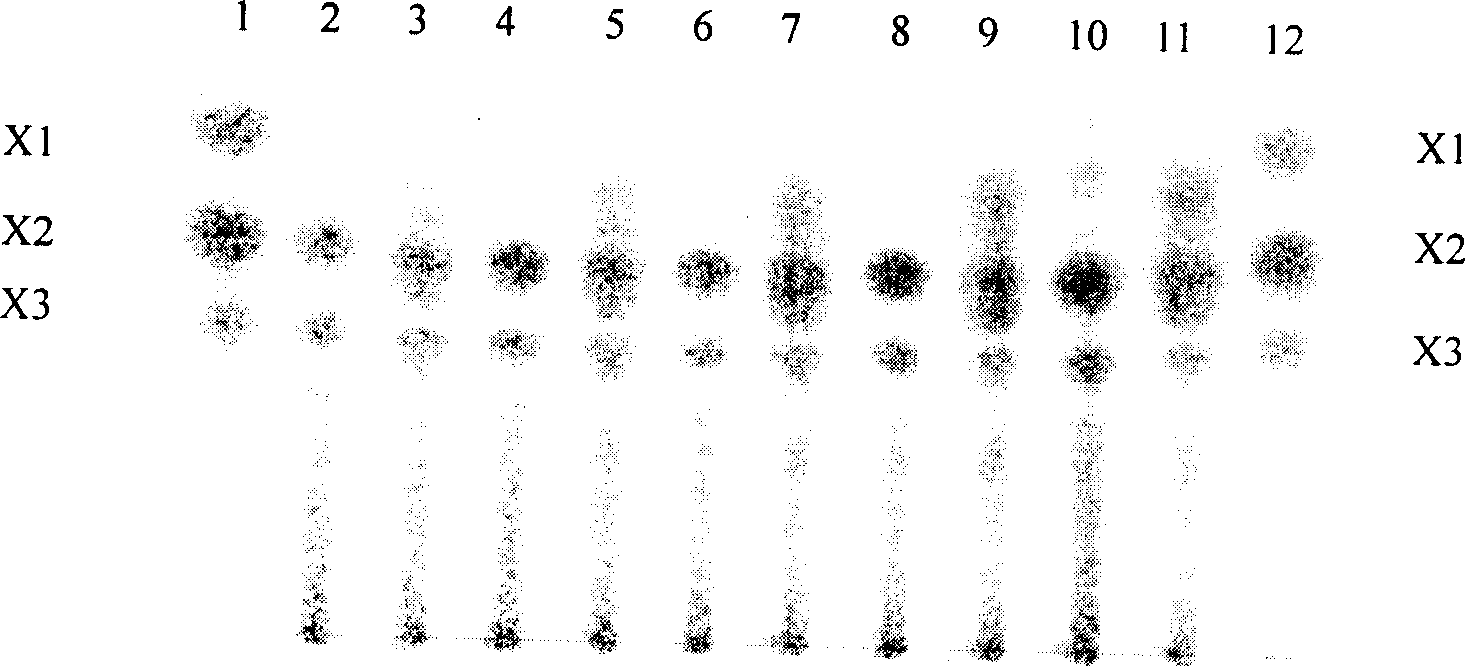

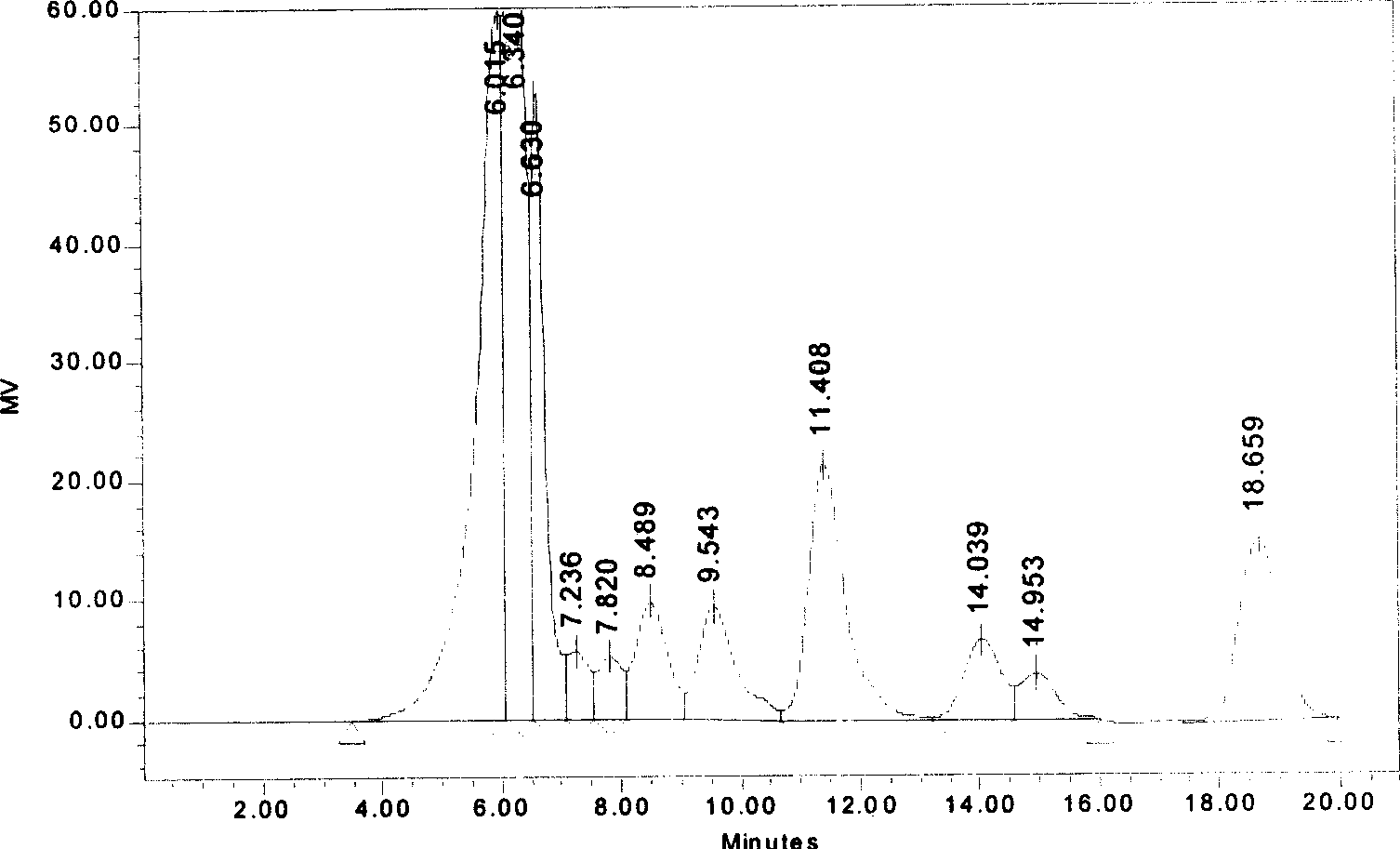

[0036] Example 2: basically the same as Example 1, the difference is that the hydrolysis temperature is 95°C, the xylan is hydrolyzed for 12 hours, and samples are taken for TLC analysis at 1.5h, 3h, 5h, 8h, and 12h of hydrolysis respectively, as figure 2 Shown; Hydrolysis 12 hours gained product carries out ion chromatographic analysis as Figure 4 shown.

Embodiment 3

[0037] Example 3: Basically the same as Example 1, the difference is that only heat-resistant xylanase is added to carry out xylan hydrolysis at 95°C for 12 hours, and samples are taken at 1.5h, 3h, 5h, 8h, and 12h of hydrolysis Perform TLC analysis, such as figure 2 Shown; Hydrolysis 12 hours gained product carries out ion chromatographic analysis as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com