Fermentation product and process for producing the same

A manufacturing method and a technology for treating objects, which are applied in chemical instruments and methods, food preparation, food science, etc., and can solve the problems of strengthening without considering the effect of antioxidant activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Manufacture of fermentation treatment product

[0036] The rhizome 30g of dried turmeric is pulverized to a particle diameter of 0.1-3mm, and put into a container. 150 g of water and 0.9 g of molasses were added to the container containing the turmeric. Carbon dioxide is supplied to the container with pulverized turmeric, and at the same time, after cultivating the bacteria of Lactobacillus plantarum, Streptococcus thermophilus, and Bacillus subtilis, mix them in a ratio of 1:1:1, and use 10% of the weight of turmeric. % ratio, airtight container, fermented by static culture. The fermentation temperature is 40°C, and the fermentation time is 72 hours. Thereafter, it was dried at 60° C. with a drier so that the water content would be 10% by weight or less. Sterilize (130° C. steam, 5-15 seconds) to obtain 30 g of fermented turmeric.

Embodiment 2

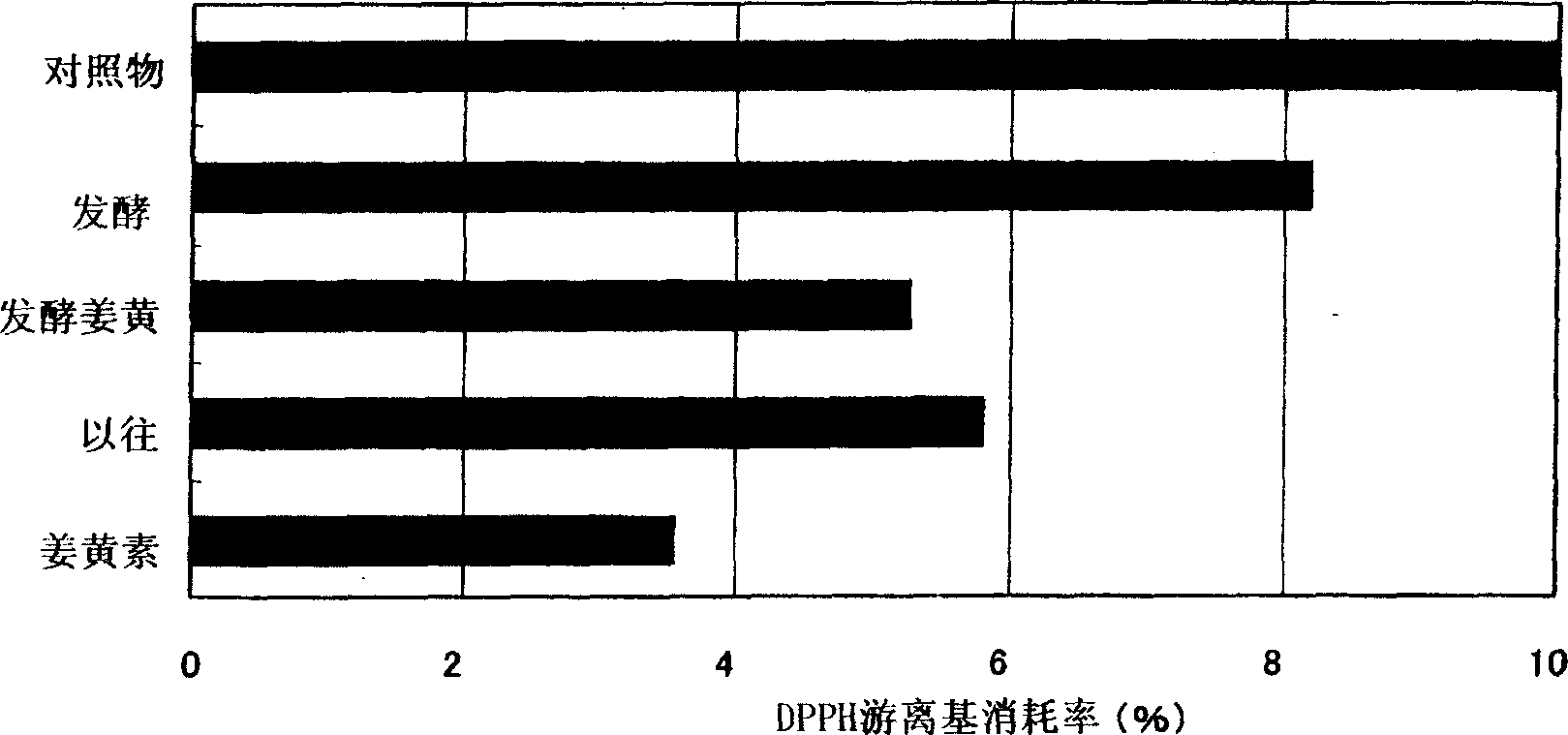

[0037] Example 2: Determination of Antioxidant Activity of Fermentation Treatment

[0038] Using the fermented turmeric prepared in Example 1, 1 mg of the fermented turmeric was extracted with 1 mL of 80% ethanol to prepare a sample. To 0.05 mL of the sample, 0.95 mL of 0.05 M Tris-HCl buffer solution (pH 7.4) (manufactured by Wako Co., Ltd.), 1.0 mL of 0.1 mM DPPH-ethanol solution (manufactured by Wako Co., Ltd.) and 1.0 mL of 100% ethanol were added and mixed. mL of the resulting reagent. The absorbance (517 nm) before and 30 seconds after the addition of the reagent was measured using a spectrophotometer (UV-1200V manufactured by Shimadzu Corporation). Water was used as a control, and the difference in absorbance before and after adding the reagent was taken as 100 for the control, and the difference in absorbance before and after adding the reagent in the sample was used as the free radical consumption rate. The results are shown in Table 4.

[0039] Table 4 shows the r...

Embodiment 3

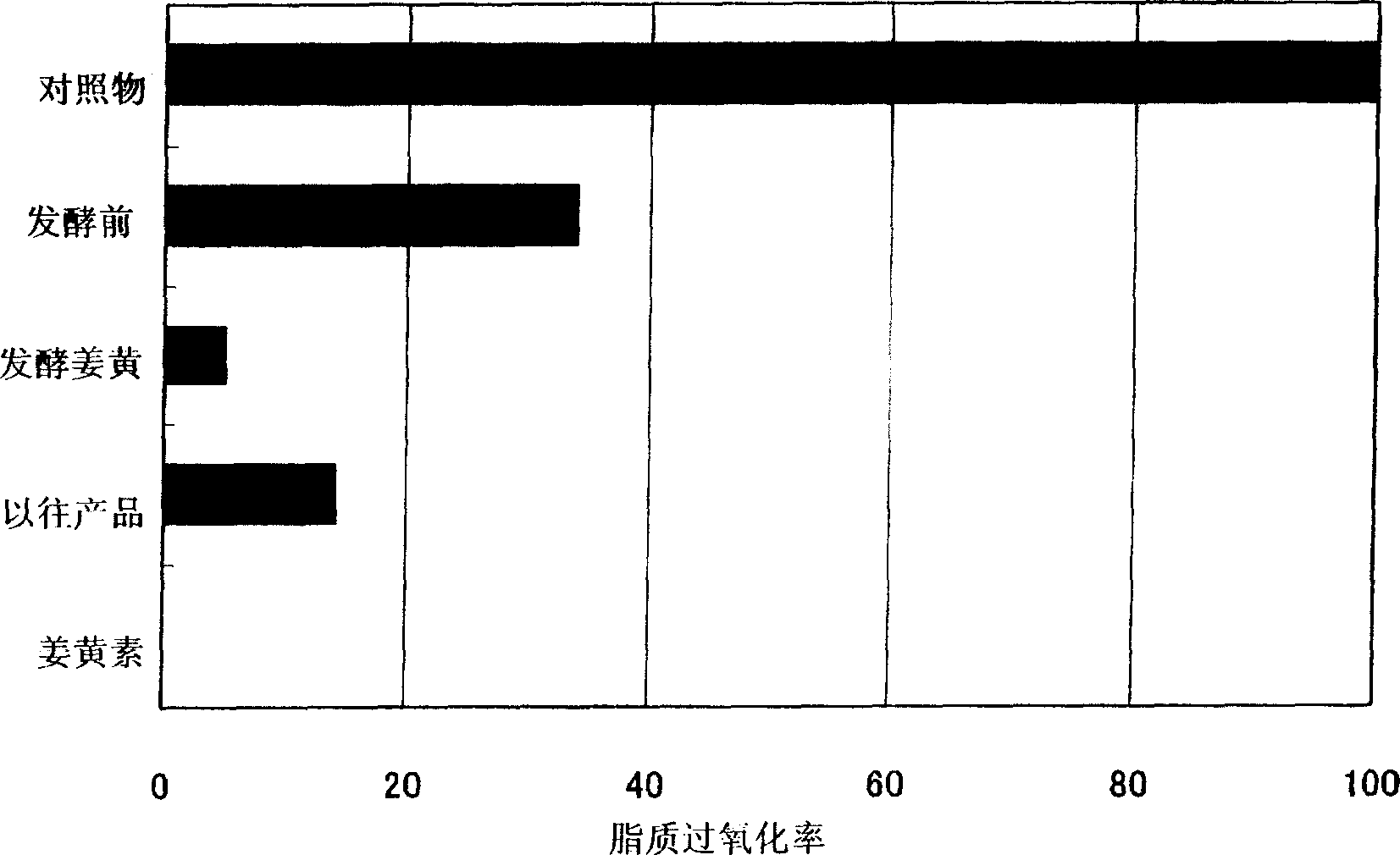

[0042] Example 3: Determination of Antioxidant Activity of Fermentation Treatment

[0043] Extract the fermented curcuma longa 1g that is made by embodiment 1 with 80% ethanol 50mL. Add 0.4mL of ethanol, 0.4mL of water, 0.8mL of 50mM phosphate buffer (pH7.0), 0.4mM of 2.5% linoleic acid / ethanol solution to 10mL of the extracted sample, and place it in a constant temperature bath at 40°C for 7 days . To this mixed liquid 0.1 mL were added 4.7 mL of 75% ethanol aqueous solution, 0.1 mL of 30% ammonium thiocyanate, and 0.1 mL of 20 mM ferrous chloride / 3.5% hydrochloric acid. The absorbance at a wavelength of 500 nm after 3 minutes was measured using a spectrophotometer (UV-1200V manufactured by Shimadzu Corporation). The results are shown in Table 5. As a control, an aqueous 80% ethanol solution was used, and the absorbance of the sample was determined as the lipid peroxidation rate with the difference in absorbance of the control sample being 100. The results are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com