Water-based polyurethane resin and its electrophoretic paint composition and preparing method

A water-based polyurethane and resin technology, applied in the field of polyurethane electrophoretic paint and its manufacturing, can solve the problems of unsatisfactory comprehensive performance and achieve the effect of improving water resistance and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

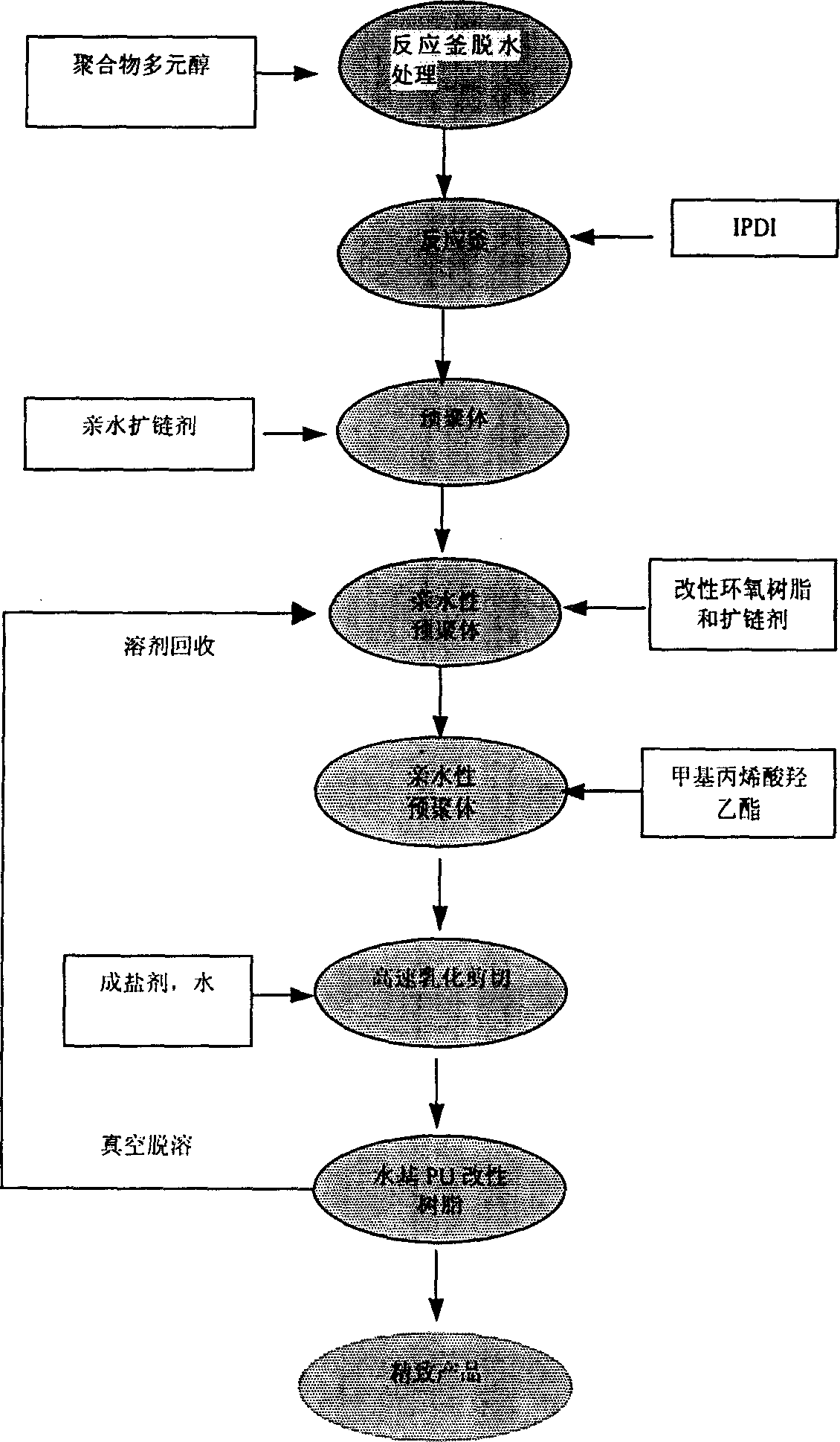

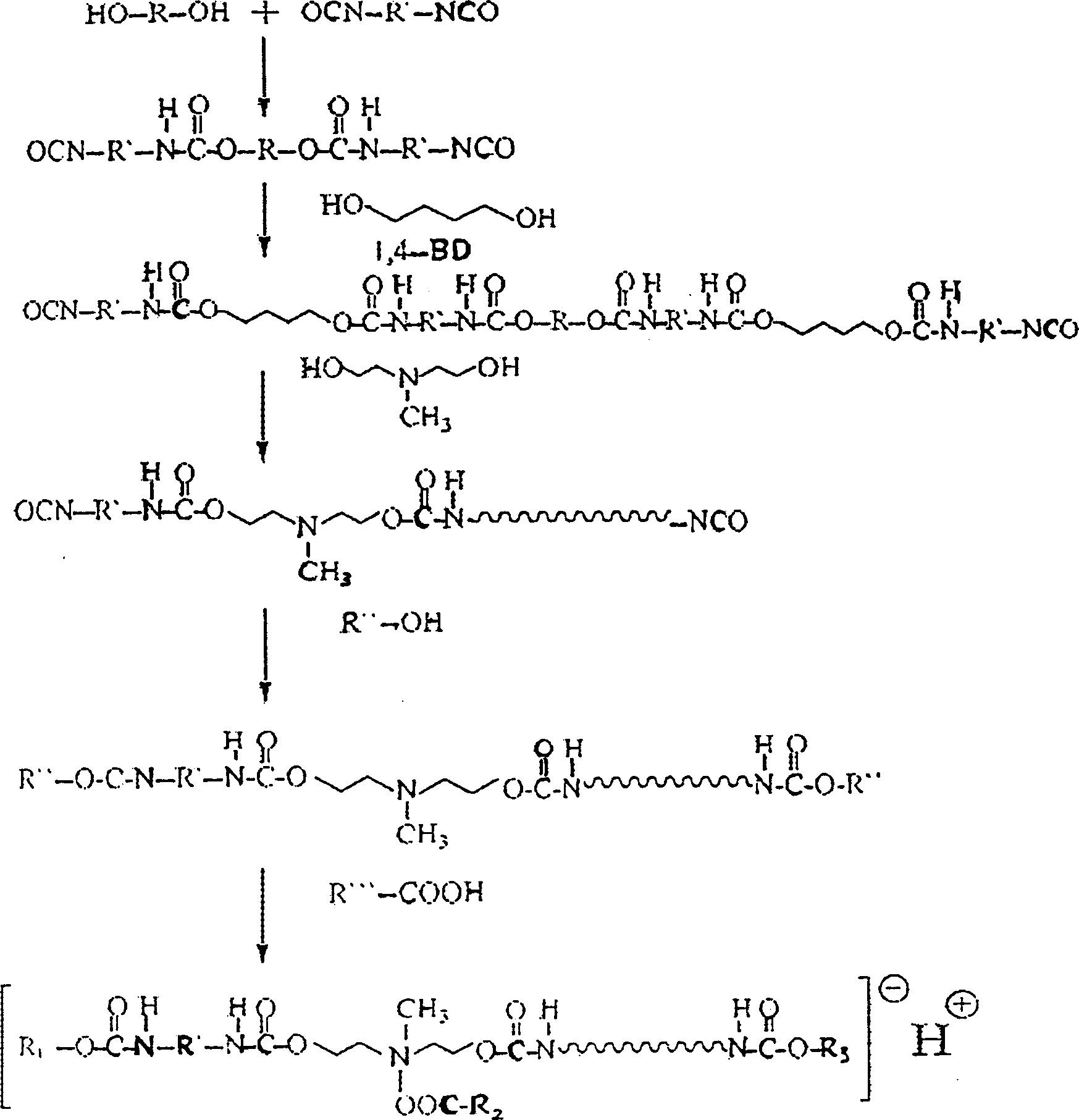

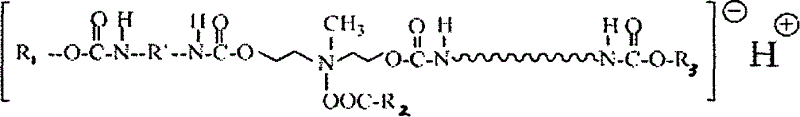

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: get the polyester polyol 23g that molecular weight is 5000, react 2 hours at 75 ℃ with isophore diisocyanate (1PDI) 36g, then in the presence of solvent dioxane, with dimethylolpropionic acid 10g React at 75°C for 2 hours, and then react with 16g of methacrylic acid modified hydroquinone epoxy resin, 8g of glycerol, and 8g of 1,4-butanediol at 75°C for 2 hours of chain extension reaction. Under the action of tin, carry out capping reaction with 5 g of hydroxyethyl methacrylate at 70° C. for 3 hours, finally cool down to 40° C., add 6 g of acetic acid for neutralization reaction for 0.5 hours to prepare water-based polyurethane resin.

[0049] Add 5g of photoinitiator benzoin ethyl ether, 3g of color paste, and 0.1g of defoamer to the above-mentioned water-based polyurethane resin. After emulsification and shearing in water, free radical polymerization occurs under the action of ultraviolet light after the colloidal particles are formed into a film. Polyure...

Embodiment 2

[0050] Example 2: Take 30g of polyether polyol with a molecular weight of 3000, react with 25g of methyl diisocyanate at 40°C for 4 hours, then react with 7g of dimethylol butyric acid at 40°C in the presence of solvent acetone After 1 hour, with 20g of methacrylic acid modified hydroquinone epoxy resin and 10g of glycerol at 50°C for chain extension reaction for 2 hours, under the action of catalyst propyl lead, react with methacrylic acid hydroxyl at 50°C 3 g of ethyl ester was subjected to capping reaction for 5 hours, and finally the temperature was lowered to 10° C., and 5 g of lactic acid was added for neutralization reaction for 1 hour to prepare a water-based polyurethane resin.

[0051] Then add 5g of photoinitiator methyl ether to the above water-based polyurethane resin, emulsify and shear in water, and after the colloidal particles form a film, under the action of ultraviolet light, free radical polymerization occurs to cause secondary crosslinking to prepare polyur...

Embodiment 3

[0052] Embodiment 3: Get the polyether polyol 23g that molecular weight is 6000, and 2,4-diphenylmethane diisocyanate 25g react at 60 ℃ for 6 hours, then in the presence of solvent ethyl ketone, with dimethylol butyl React 8g of acid at 60°C for 6 hours, then react with 18g of methacrylic acid modified hydroquinone epoxy resin, 2g of malonic acid, 5g of xylitol, and 4g of diethylene glycol at 80°C for 2 hours after chain extension reaction , under the action of catalyst cycloalkyl tin, carry out capping reaction with 6g of hydroxyethyl acrylate at 80°C for 5 hours, and finally cool down to 60°C and neutralize with 7g of acetic acid for 2 hours to make water-based polyurethane resin.

[0053] Then add 6g of photoinitiator benzophenone to the above water-based polyurethane resin, emulsify and shear in water, and after the colloidal particles form a film, under the action of ultraviolet light, free radical polymerization occurs to cause secondary crosslinking. Polyurethane electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com