Split-charging nano composite functional coating

A technology of nanocomposite and functional coatings, which is applied in the direction of coatings and devices for coating liquid on the surface, which can solve the problems of unstable function and quality of nanocomposite coatings, inability to exert nano-efficiency, and poor efficacy of nano-materials, and achieve improved Functional effects, improved scrub resistance, and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The first step A component preparation

[0019] Weigh 5.0g composite nanopowder (TiO 2 , 3.5g, ZnO 0.5g, SiO 2 1.0g) in 500ml deionized water, carry out primary ultrasonic dispersion for 2h, then add water-soluble polymer polyvinyl alcohol aqueous solution (CMC 1.0%), the addition amount is 1000ppm of the dispersion liquid weight, add film-forming agent silica sol (SiO 2 8%), the dosage is 10% of the weight of the dispersion liquid, and continue to ultrasonically disperse for 48 hours (continuously replenishing the water lost in the process) to obtain component A.

[0020] The second step B component preparation

[0021] Mix 100ml deionized water, 0.75ml defoamer (NXZ), 0.5ml wetting agent (X-405), 1.5ml dispersant (SN-5040), 4.0ml dispersant (SN-5027), 10ml antifreeze propylene glycol , 1.0ml of pH regulator (AMP-95) was added to a 1000ml high-speed mixer, 75.0g of rutile titanium dioxide (CR-828), 30.0g of calcined kaolin (1250 mesh), 50.0g of heavy calcium (800 m...

Embodiment 2

[0030] Step 1 Preparation of Component A

[0031] Prepare component A in the same manner as in Example 1.

[0032] Step 2 Component B Preparation

[0033] 90ml deionized water, 1.5ml defoamer (NXZ), 1.0ml wetting agent (X-405), 1.5ml dispersant (SN-5040), 1.5ml dispersant (SN-5027), 1.5ml pH adjustment Add AMP-95, 13ml propylene glycol to a 1000ml high-speed mixer, then add 125.0g rutile titanium dioxide (CR-828), 25.0g calcined kaolin (1250 mesh), 25.0g heavy calcium carbonate (800 mesh) , 25.0g of barite powder (800 mesh) was subjected to high-speed sand milling for 30min, then added 50.0ml of 3.0% hydroxyethyl cellulose aqueous solution, continued high-speed sand milling for 0.5-1h, and transferred the pigment and filler slurry into the paint mixing tank, at low speed Stir, add 170.0ml of pure acrylic emulsion (1135), 14ml of alcohol ester-12, 2.0ml of thickener (SN612), 1.5ml of defoamer (CF-16), and continue to stir at low speed for 0.5~1h to prepare component B.

[00...

Embodiment 3

[0039] Step 1 Preparation of Component A

[0040] Weigh 10.0g composite nanopowder (TiO 2 , 6.0g, ZnO 1.5g, SiO 2 2.5g) add 500ml of deionized water, carry out primary ultrasonic dispersion for 2h first, then add water-soluble polymer polyvinyl alcohol aqueous solution (1% CMC), the addition amount is 1000ppm of dispersion liquid weight, add film-forming agent silica sol (SiO 2 8%), the amount added is 10% of the dispersion liquid weight, and the ultrasonic dispersion is continued for 48 hours, and the lost moisture is replenished in the process.

[0041] Step 2 Component B Preparation

[0042] Prepare according to the same method as in Example 1.

[0043] The third step A, B component compound

[0044] Make according to the same method of embodiment 1.

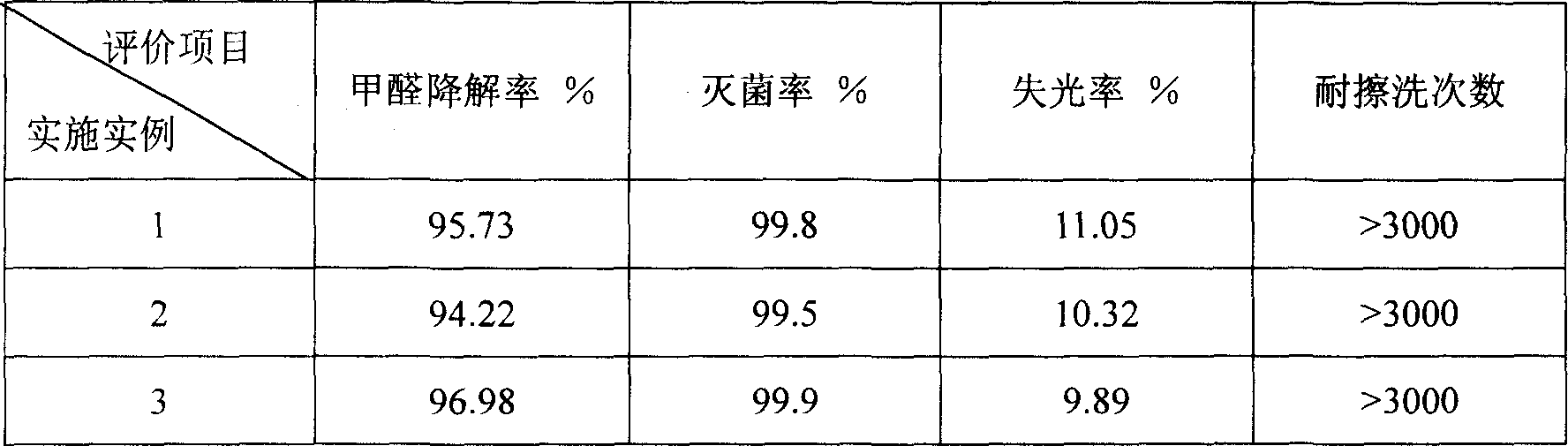

[0045] The fourth step is to evaluate the performance of nanocomposite functional coating film

[0046] According to the same method evaluation of embodiment 1, performance index is shown in table 1.

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com