Biological activity glass ceramics capable of cutting and its preparation method

A bioactive glass and ceramic technology, applied in the field of silicate materials, can solve the problems of difficult processing and difficult application of bioceramics, and achieve the effects of easy operation, good bioactivity and biocompatibility, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

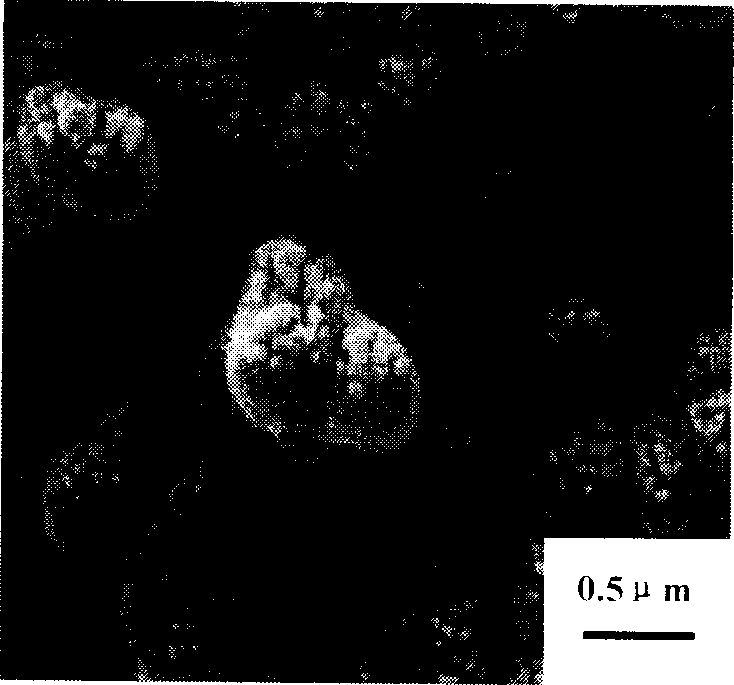

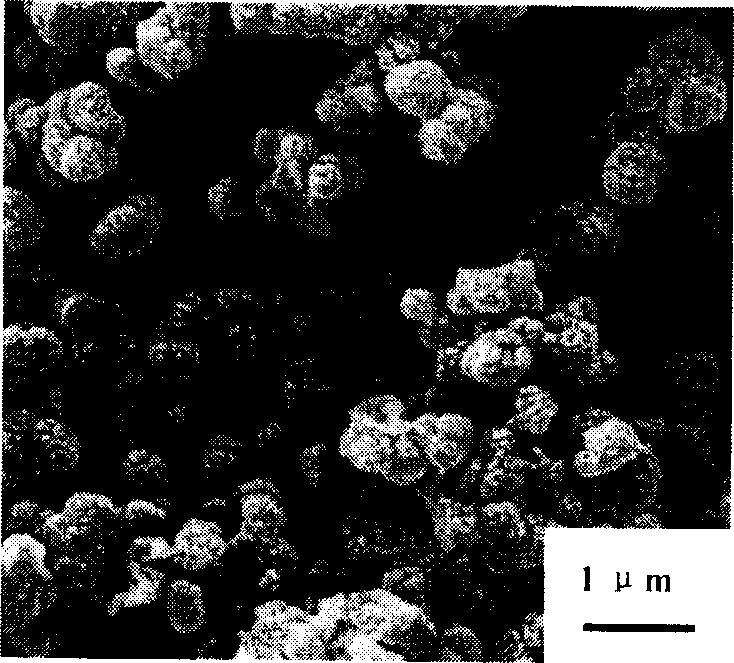

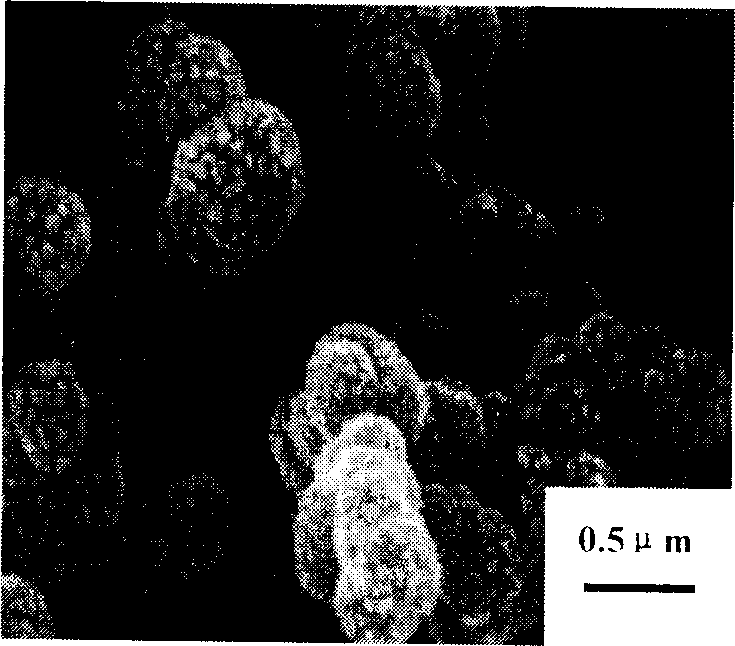

Image

Examples

Embodiment 1

[0013] Embodiment 1: by SiO 2 51.6%, Al 2 o 3 10.4%, MgO13.3%, NaF14.8%, CaHPO 4 6.3%, CaCO 3 2.7%, CaF 2 Mix 1.0% ingredients; pour into an alumina crucible, melt in a silicon-molybdenum rod furnace at 1500°C for 2 hours, and the heating rate is 5°C / min; 74μm or less; these glass powders are remelted under the same conditions and then cast into graphite molds. Before that, the molds were heated to 500-600°C, and the graphite molds were immediately moved into the heating furnace and kept at 650°C for 1 hour. Cool to obtain a glass matrix; then heat the glass matrix from room temperature to 925°C for 6 hours at a heating rate of 10°C / min, and take it out after cooling to room temperature with the furnace. After processing and grinding the prepared glass ceramics, the size is 3×4×35mm. The flexural strength is 110MPa and the elastic modulus is 8GPa by using the three-point bending method on a CSS-44100 electronic universal testing machine.

[0014] Or after obtaining the g...

Embodiment 2

[0017] Embodiment 2: by SiO 2 51.6%, Al 2 o 3 10.4%, MgO13.3%, NaF14.8%, CaHPO 4 6.3%, CaCO 3 2.7%, CaF21.0% ingredients and mix well; pour into alumina crucible, melt in silicon molybdenum rod furnace at 1500°C for 2 hours, heating rate is 5°C / min; pour molten glass into water to cool, After drying, ball mill to less than 74μm; these glass powders are remelted under the same conditions and cast into graphite molds. Before that, the molds were heated to 500-600°C, and the graphite molds were immediately moved into the heating furnace and kept at 650°C. After 1 hour, cool with the furnace to obtain the glass matrix; then raise the temperature of the glass matrix from room temperature to 1050°C for 6 hours at a heating rate of 10°C / min, and take it out after cooling to room temperature with the furnace. After processing and grinding the prepared glass ceramics, the size is 3×4×35mm. The flexural strength is 129MPa and the elastic modulus is 11GPa by three-point bending metho...

Embodiment 3

[0021] Embodiment 3: by SiO 2 45.9%, Al 2 o 3 9.2%, MgO11.8%, NaF13.1%, CaHPO 4 12.6%, CaCO 3 5.4%, CaF 2 Mix 2.0% ingredients; pour into an alumina crucible, melt in a silicon-molybdenum rod furnace at 1500°C for 2 hours, and the heating rate is 5°C / min; pour the molten glass into water to quench, dry and ball mill to 74μm or less; these glass powders were remelted under the same conditions and then cast into graphite molds; before the mold was heated to 500-600°C, the graphite mold was immediately moved into the heating furnace and kept at 650°C for 1 hour and then the furnace Cool to obtain a glass matrix; then heat the glass matrix from room temperature to 925°C for 6 hours at a heating rate of 10°C / min, and take it out after cooling to room temperature with the furnace. The obtained glass-ceramic samples are processed and polished, and the size is 3×4×35mm. The flexural strength is 134MPa and the elastic modulus is 12GPa by three-point bending method on a CSS-44100 e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com