Irradiant polymer/nanometer sulfide composite material and its preparation

A technology of light-emitting polymers and composite materials, applied in the direction of light-emitting materials, chemical instruments and methods, etc., can solve the problems of high surface free energy, difficulty in stabilizing the system, large surface area, etc., and achieve controllable polymerization process, clear product structure, The effect of increased reactive functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Synthesis of poly-o-methyl-acrylamide-benzoic acid

[0024] (1) Synthesis of monomeric methyl-acrylamido-benzoic acid

[0025] 40ml-80ml tetrahydrofuran, 5.5g-11g anthranilic acid, stirred and dissolved in an ice-water bath, then added triethylamine with a molar ratio of 1.2:1 to anthranilic acid, stirred for half an hour, slowly added methacryloyl chloride ( The molar ratio to anthranilic acid is 1.2:1), react in an ice-water bath for 0.5h-1h, continue to react at room temperature for 3h-5h, stop the reaction, filter with suction, wash the filtrate with ether, and drop it into the washed solution while stirring Add hydrochloric acid to obtain a white powder, filter it with suction, and dry it in vacuum to obtain methyl-acrylamido-benzoic acid.

[0026] (2) Atom transfer radical polymerization of meth-acrylamido-benzoic acid

[0027] In meth-acrylamido-benzoic acid, sodium hydroxide, ligand 2,2'-bipyridyl molar ratio 50:50:3, add N,N'-dimethylformaldehyde w...

Embodiment 2

[0028] Example 2: Using poly-o-methyl-acrylamide-benzoic acid as a template to generate nano-ZnS in situ

[0029] Mass ratio is 1: 1-10: 1 poly-o-methyl-acrylamido-benzoic acid and zinc acetate, add deionized water (make the zinc ion concentration in the solution be about 9.2 × 10 -2 mol / l--9.2×10 -3 mol / l), stirred at room temperature for 48h-72h, filtered, washed with water and dried to obtain poly-o-methyl-acrylamide-benzoic acid-Zn. Poly-o-methyl-acrylamide-benzoic acid-Zn is stirred with an aqueous solution of excess sodium sulfide for 3h-5h, filtered, washed with water and dried to obtain poly-o-methyl-acrylamide-benzoic acid-ZnS.

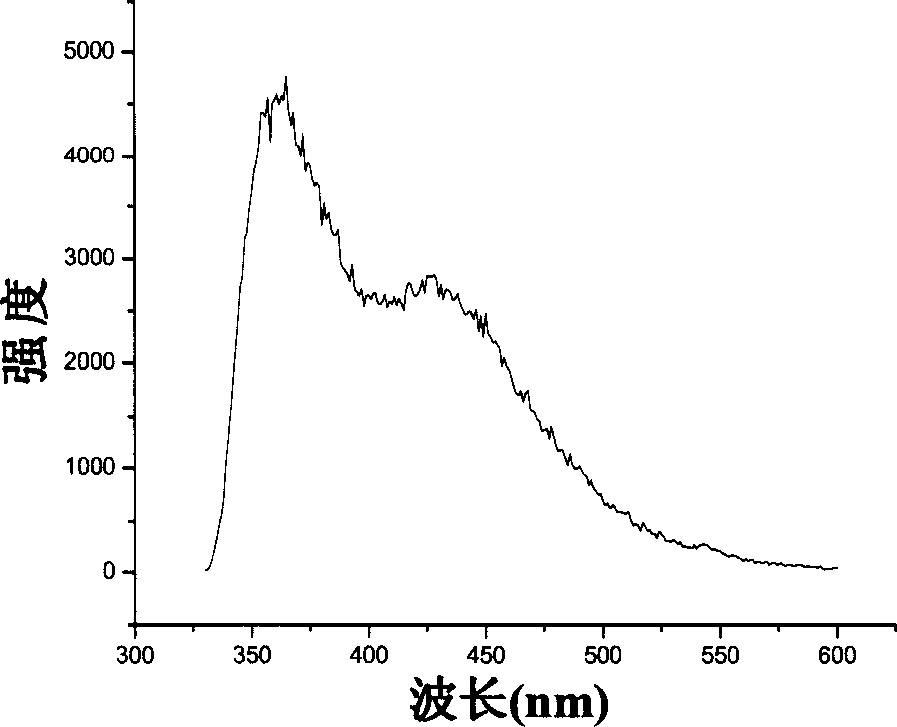

[0030] The fluorescence spectrum of the composite system after generating ZnS is shown in the attached figure 1 Shown: Under the excitation wavelength of 314nm, the composite system has emission peaks at 370nm and 425nm, which are respectively the emission peak of poly-o-methyl-acrylamide-benzoic acid and the self-activation peak of ZnS.

Embodiment 3

[0031] Example 3: In situ generation of nano-ZnS with poly-o-methyl-acrylamide-benzoic acid as a template

[0032] Mass ratio is 1: 1-10: 1 poly-o-methyl-acrylamido-benzoic acid and zinc acetate, add deionized water (make the zinc ion concentration in the solution be about 9.2 × 10 -2 mol / l--9.2×10 -3 mol / l), stirred at room temperature for 48h-72h, filtered, washed with water and dried to obtain poly-o-methyl-acrylamide-benzoic acid-Zn. Poly-o-methyl-acrylamide-benzoic acid-Zn and excess thioacetamide aqueous solution were stirred and reacted at 80°C for 60-100 minutes, filtered, washed with water and dried to obtain poly-o-methyl-acrylamide-benzene Formic acid-ZnS.

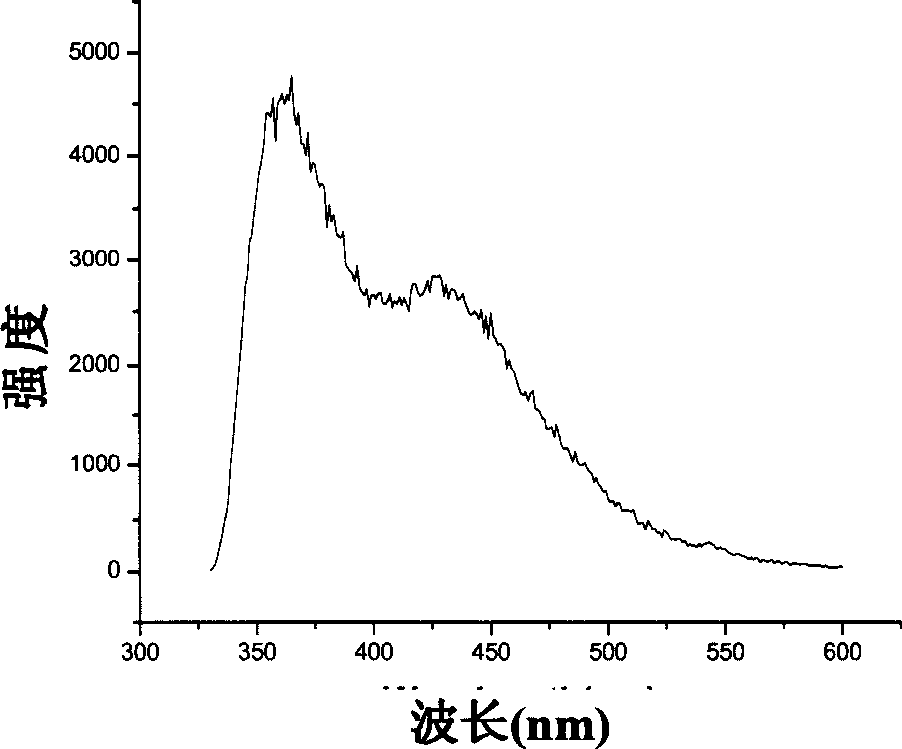

[0033] The fluorescence spectrum of the composite system after generating ZnS is shown in the attached figure 2 Shown: Under the excitation wavelength of 314nm, the composite system has emission peaks at 370nm and 425nm, which are respectively the emission peak of poly-o-methyl-acrylamide-benzoic acid and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com