Inverse emulsion process of preparing amphoteric polymer

An amphoteric polymer and amphoteric monomer technology, applied in the field of water-soluble polymer synthesis, can solve the problems of low intrinsic viscosity of amphoteric polymers, difficult industrialization implementation, water solubility differences, etc., and achieves fast polymerization rate, high yield, molecular high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

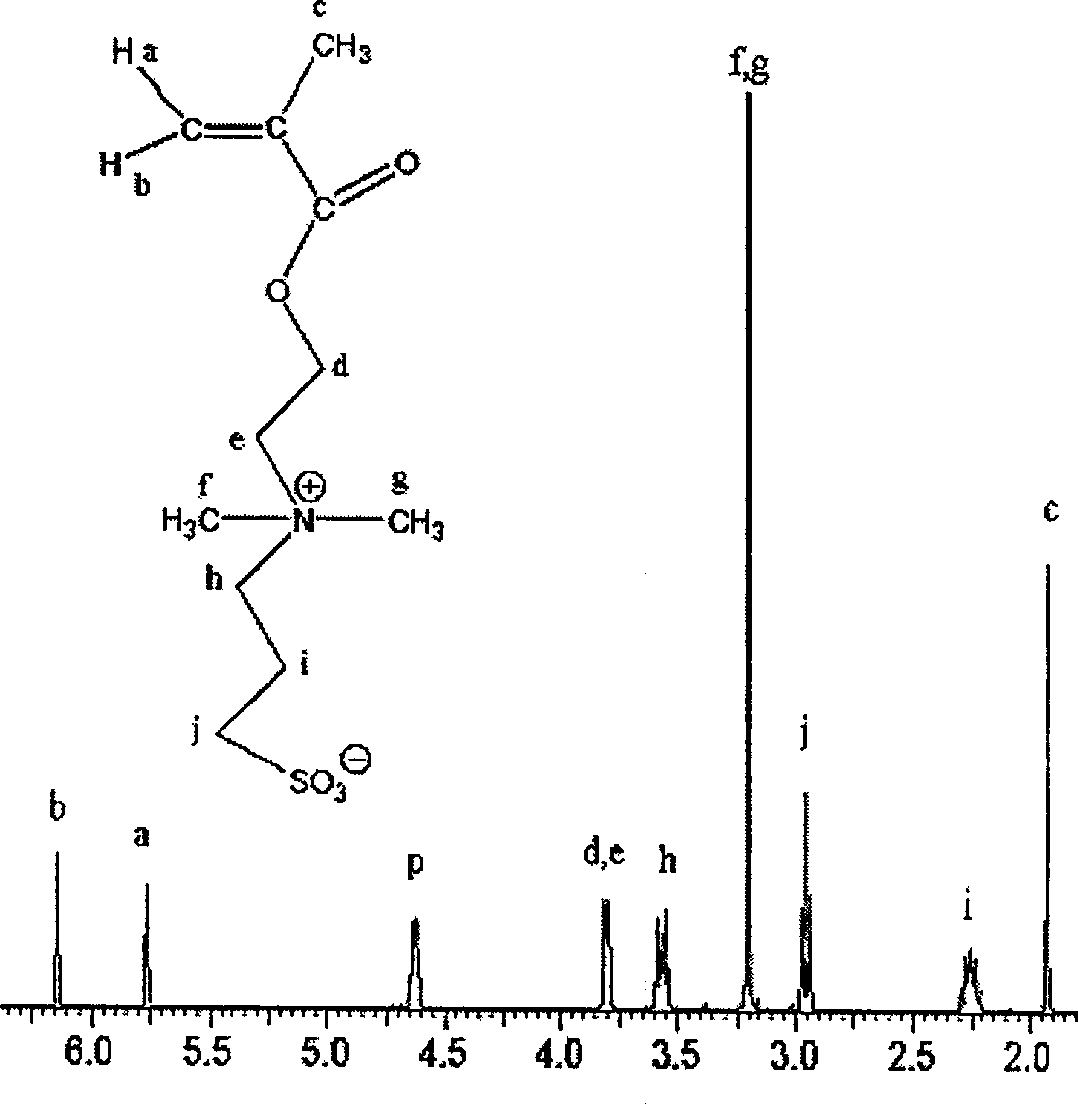

[0053] Embodiment 1. Preparation of amphoteric monomer DMPS

[0054] Weigh 20g of propane sultone and dissolve it in 60g of acetone, pour it into a 400mL four-necked bottle equipped with a condenser tube, a thermometer, a constant pressure dropping funnel and an electric stirrer, then put it in a constant temperature water bath at 30°C, and start stirring . Weigh 30g of DMAEMA and dissolve it in 40g of acetone, then pour it into a constant pressure dropping funnel and slowly drop it into a four-necked bottle for 2 hours, then raise the temperature to 35°C for 1 hour, stop the reaction, pour it into a Buchner funnel to filter, After rinsing three times with a little acetone, put into 50 ℃ of vacuum ovens and dry 4h, obtain white powdery product 46.4g, productive rate ≥ 92.8%, identify product as amphoteric monomer DMPS (such as figure 1 shown).

Embodiment 2

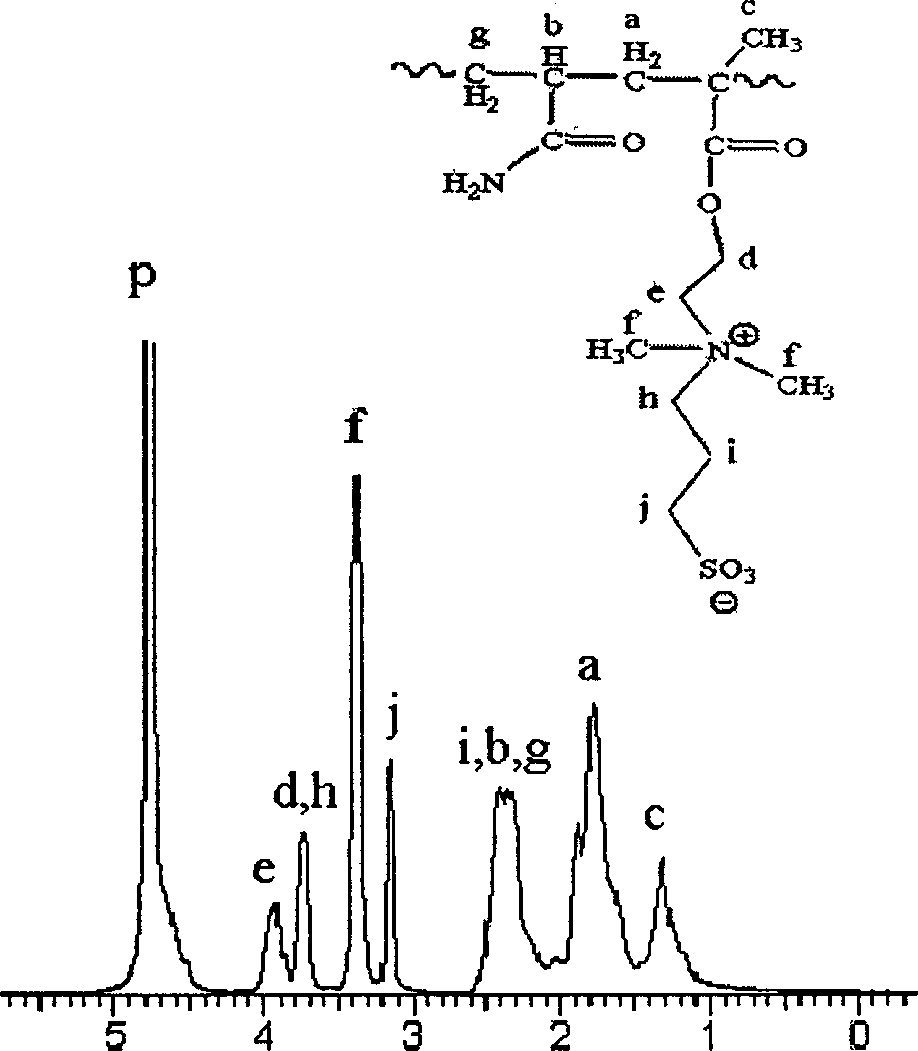

[0055] Embodiment 2. Preparation of amphoteric copolymer

[0056] Oil phase: Measure 20mL of cyclohexane, weigh 2.0g of Span 80 and dissolve it, add it to a four-neck flask equipped with a stirrer, condenser, nitrogen pipe and dropping funnel, and pass N under stirring. 2 Deoxygenation for half an hour. Water phase: weigh 9g AM and 8g DMPS and dissolve in 30mL water, then add 0.2mL (0.15mol L -1 ) of TMEDA and 0.2mL (0.15mol·L -1 ) DMAEMA solution, pass N 2 Deoxygenation for half an hour. In the case of high-speed stirring (speed ≥ 1100r / min), slowly add the water phase to the oil phase dropwise, 30 ~ 60min dropwise, and finally add KPS 0.065g (dissolved in 2mL water), stir quickly for 20min and then reduce the stirring speed Adjust to about 300r / min, and at the same time transfer to 30°C constant temperature water bath to react for 5h to obtain uniform viscous milky white latex. Precipitate with absolute ethanol, dry, and pulverize to obtain 15.6g of amphoteric copolymer...

Embodiment 3

[0057] Example 3. As described in Example 2, the difference is that the monomer feed ratio is AM 13g, DMPS 4g, and the amphoteric copolymer powder product 15.8g is obtained, and the intrinsic viscosity is 8.5dL g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com